Essential Maintenance Strategies for Industrial Welding Equipment

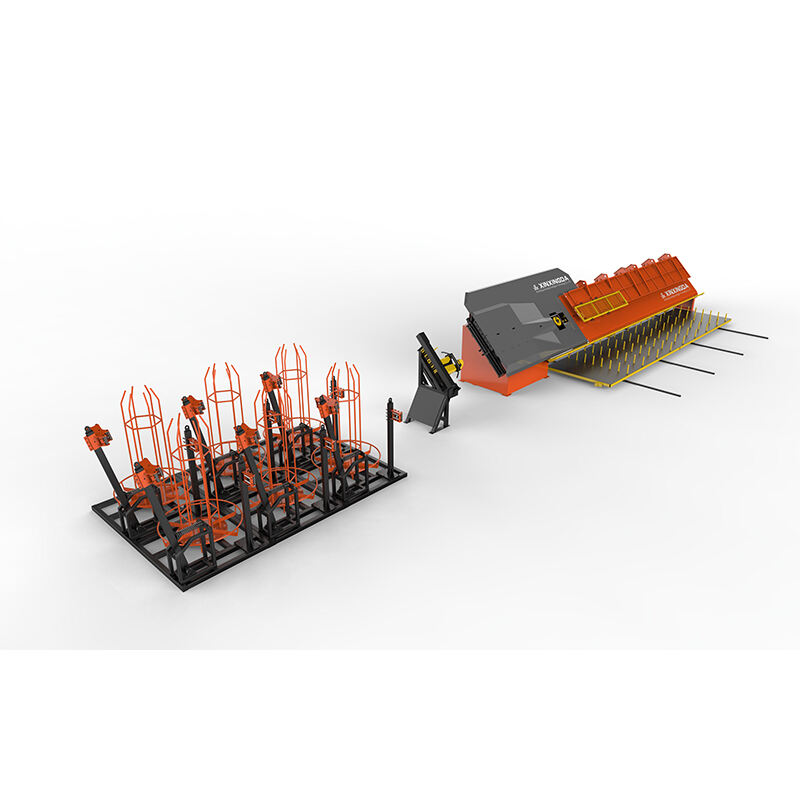

Industrial welding equipment represents a significant investment for manufacturing facilities, and proper maintenance is crucial for ensuring optimal performance and longevity. Steel cage roll welding machines, in particular, require systematic care and attention to maintain their precision and reliability. Understanding and implementing the right maintenance practices not only extends equipment lifespan but also ensures consistent production quality and reduces costly downtime.

Regular maintenance of a steel cage roll welding machine goes beyond simple cleaning and occasional repairs. It encompasses a comprehensive approach that includes preventive measures, systematic inspections, and timely interventions. This detailed guide will explore the vital maintenance practices that help maximize the service life of your welding equipment while maintaining peak performance.

Preventive Maintenance Fundamentals

Daily Inspection Protocols

The foundation of effective maintenance begins with daily inspection routines. Before each shift, operators should examine the steel cage roll welding machine for any visible signs of wear, damage, or misalignment. This includes checking the welding rolls for proper alignment, inspecting electrical connections, and verifying the smooth operation of all moving parts.

Daily maintenance tasks should include cleaning welding surfaces, checking coolant levels, and ensuring proper lubrication of moving components. These simple yet crucial steps help prevent debris accumulation and premature wear while maintaining optimal operating conditions for the steel cage roll welding machine.

Weekly Maintenance Schedule

Weekly maintenance involves more detailed inspection and servicing procedures. This includes thorough cleaning of the entire machine, checking and adjusting belt tensions, and inspecting all electrical systems. The welding rolls should be examined for wear patterns and rotated if necessary to ensure even wear distribution.

Documentation of weekly maintenance activities helps track equipment performance and identify potential issues before they develop into serious problems. This proactive approach helps maintain the steel cage roll welding machine's efficiency and prevents unexpected breakdowns.

Critical Component Care

Welding Roll Maintenance

The welding rolls are the heart of the steel cage roll welding machine and require special attention. Regular inspection for wear, proper alignment, and surface condition is essential. Rolls should be cleaned thoroughly after each production run to prevent material buildup and ensure consistent welding quality.

Proper calibration of roll pressure and alignment is crucial for achieving optimal weld quality. Technicians should regularly check and adjust these parameters according to manufacturer specifications. When wear becomes evident, rolls should be resurfaced or replaced to maintain precise welding operations.

Electrical System Care

The electrical components of a steel cage roll welding machine require regular inspection and maintenance to ensure safe and efficient operation. This includes checking all connections for tightness, examining wiring for signs of wear or damage, and testing safety systems regularly.

Regular thermal imaging inspections can help identify potential electrical issues before they cause equipment failure. Maintaining clean and dry electrical cabinets prevents moisture-related problems and extends component life.

Lubrication and Cooling Systems

Proper Lubrication Practices

Implementing a comprehensive lubrication program is essential for maintaining the steel cage roll welding machine's mechanical components. This includes using the correct type and grade of lubricants, maintaining proper oil levels, and adhering to recommended lubrication schedules.

Regular oil analysis helps monitor equipment health and determines when oil changes are necessary. Clean oil not only reduces friction and wear but also helps maintain optimal operating temperatures and extend equipment life.

Cooling System Maintenance

The cooling system plays a vital role in preventing overheating and maintaining consistent welding quality. Regular inspection and cleaning of cooling channels, heat exchangers, and radiators ensure efficient heat dissipation. Coolant levels and quality should be checked regularly, with replacement performed according to manufacturer recommendations.

Proper maintenance of the cooling system helps prevent thermal stress on components and ensures stable operation of the steel cage roll welding machine. This includes checking for leaks, cleaning filters, and maintaining proper coolant flow rates.

Environmental and Safety Considerations

Workspace Management

The environment surrounding the steel cage roll welding machine significantly impacts its performance and longevity. Maintaining a clean, temperature-controlled workspace helps prevent contamination and ensures consistent operation. Proper ventilation systems should be maintained to remove welding fumes and maintain air quality.

Regular cleaning of the work area, including removal of metal debris and dust, prevents these contaminants from affecting machine operation. Implementing proper storage practices for materials and tools helps maintain an organized and safe working environment.

Safety System Maintenance

Regular inspection and testing of safety systems are crucial for protecting both operators and equipment. This includes checking emergency stops, safety guards, and warning systems. All safety devices should be tested according to manufacturer specifications and regulatory requirements.

Maintaining detailed safety inspection records helps ensure compliance with workplace safety regulations while protecting the investment in your steel cage roll welding machine.

Frequently Asked Questions

How often should professional maintenance be performed on a steel cage roll welding machine?

Professional maintenance should be scheduled at least quarterly, with more frequent service intervals for machines operating in heavy-duty applications or multiple shifts. Additionally, annual comprehensive inspections are recommended to assess overall machine condition and address any developing issues.

What are the signs that welding rolls need replacement?

Key indicators include uneven wear patterns, decreased weld quality, unusual noise during operation, and visible surface damage. Regular measurements of roll diameter and surface condition help determine when replacement is necessary.

How can operators maximize the efficiency of daily maintenance routines?

Implementing a standardized checklist, providing proper training, and establishing clear communication channels between shifts helps ensure thorough daily maintenance. Digital maintenance tracking systems can also improve efficiency and accountability in maintenance procedures.

What role does operator training play in equipment maintenance?

Proper operator training is essential for early problem detection and maintaining equipment condition. Well-trained operators can identify potential issues before they become serious, perform basic maintenance tasks correctly, and operate the equipment within design parameters to prevent premature wear.