Understanding Industrial-Grade Metal Forming Technology

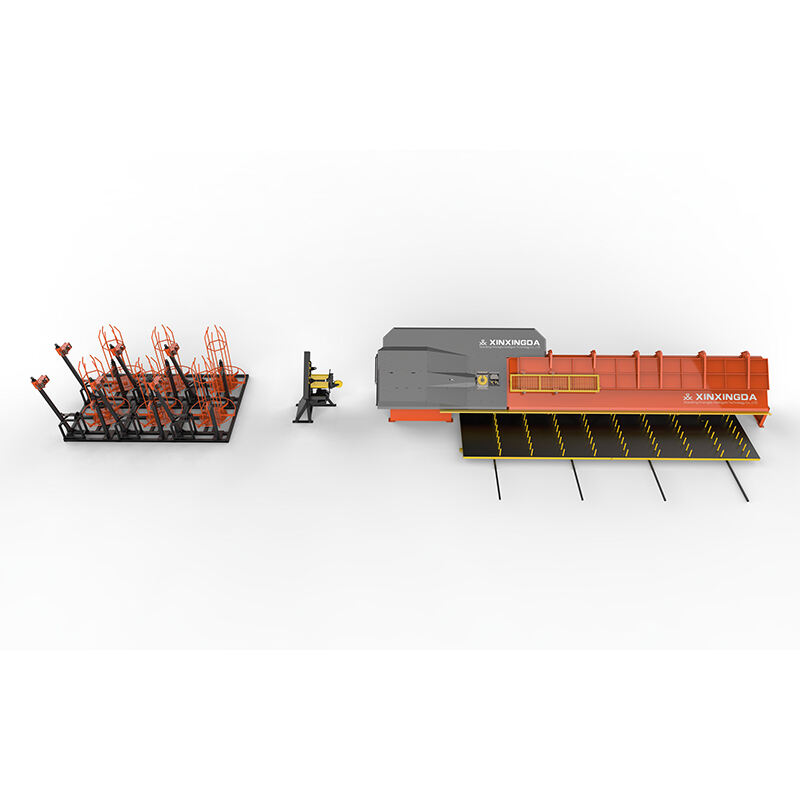

The construction industry relies heavily on precision and power when it comes to shaping metal components for major infrastructure projects. Large-scale bending machines represent the pinnacle of metal forming technology, capable of manipulating massive steel plates, beams, and pipes with exceptional accuracy. These sophisticated systems combine robust mechanical engineering with advanced control systems to handle the most demanding construction requirements.

Core Components and Capabilities of Heavy-Duty Bending Systems

Advanced Hydraulic Systems and Power Distribution

The heart of large-scale bending machines lies in their sophisticated hydraulic systems. These systems generate the immense force needed to bend thick metal plates and structural components. Modern hydraulic configurations utilize synchronized cylinders and precision-controlled pressure distribution to ensure uniform bending across the entire workpiece. The latest machines incorporate smart pressure sensors and real-time monitoring to maintain consistent force application throughout the bending process.

Structural Framework and Support Mechanisms

To handle extreme loads, large-scale bending machines feature reinforced steel frames and enhanced support structures. The main frame must withstand not only the direct bending forces but also the reactive forces generated during operation. Support rollers and guide systems help distribute the weight of heavy materials while ensuring precise positioning throughout the bending cycle. These structural elements are engineered with significant safety margins to prevent deflection and maintain accuracy even under maximum loads.

Digital Control Systems and Automation Features

Modern large-scale bending machines incorporate sophisticated CNC systems that control every aspect of the bending process. These digital interfaces allow operators to program complex bending sequences with multiple radius changes and varying angles. The automation systems manage material handling, positioning, and bending parameters while collecting real-time data for quality control and process optimization.

Material Handling and Processing Capabilities

Maximum Load Capacity and Material Dimensions

Large-scale bending machines are designed to handle materials ranging from thick steel plates to massive structural beams. The most powerful systems can process plates up to several inches thick and lengths exceeding 40 feet. Weight capacity often reaches several tons, allowing these machines to bend the heaviest construction components with precision. The ability to handle such substantial loads makes these machines indispensable for major infrastructure projects, shipbuilding, and heavy industrial construction.

Material Flow and Positioning Systems

Efficient material handling is crucial for processing heavy construction loads. Advanced large-scale bending machines feature integrated roller systems and servo-driven positioning mechanisms that facilitate smooth material movement. These systems reduce operator effort while ensuring accurate alignment before and during the bending process. Automated material handling solutions help prevent workplace injuries and increase operational efficiency when dealing with massive workpieces.

Safety Features and Operational Considerations

Integrated Safety Systems and Emergency Controls

Safety is paramount when operating large-scale bending machines. Modern systems incorporate multiple safety features, including light curtains, emergency stop systems, and operator presence detection. These machines also feature advanced overload protection mechanisms that prevent damage to both the equipment and materials being processed. Regular safety training and certification programs ensure operators understand proper procedures and emergency protocols.

Maintenance Requirements and Performance Optimization

Regular maintenance is essential for maintaining the performance and reliability of large-scale bending machines. This includes scheduled hydraulic system maintenance, calibration of control systems, and inspection of wear components. Predictive maintenance programs utilizing IoT sensors and data analytics help prevent unexpected downtime and optimize machine performance. Proper maintenance ensures consistent bending quality and extends the operational life of these substantial investments.

Applications and Industry Impact

Infrastructure Development Projects

Large-scale bending machines play a crucial role in major infrastructure projects, including bridge construction, tunnel support systems, and large-scale building frameworks. These machines enable the creation of precisely curved structural elements that form the backbone of modern architectural designs. The ability to bend heavy materials on-site reduces transportation costs and allows for greater flexibility in construction scheduling.

Industrial Manufacturing Applications

Beyond construction, large-scale bending machines are essential in manufacturing operations that produce heavy equipment, storage tanks, and industrial vessels. The precision bending capabilities allow manufacturers to create complex shapes while maintaining structural integrity. This versatility makes these machines valuable assets in shipyards, power plant construction, and other heavy industrial applications.

Frequently Asked Questions

What maximum thickness can large-scale bending machines typically handle?

Large-scale bending machines can typically handle plate thicknesses up to 6 inches (150mm) depending on the material type and machine specifications. Some specialized machines can process even thicker materials for specific applications.

How do these machines maintain accuracy with heavy loads?

These machines maintain accuracy through a combination of robust mechanical design, precise hydraulic control systems, and advanced digital monitoring. Real-time feedback systems continuously adjust bending parameters to ensure consistent results regardless of material weight.

What types of materials can be processed using large-scale bending machines?

Large-scale bending machines can process various materials including carbon steel, stainless steel, aluminum alloys, and specialized metals. The machines can be configured to handle different material properties while maintaining precise bending control.