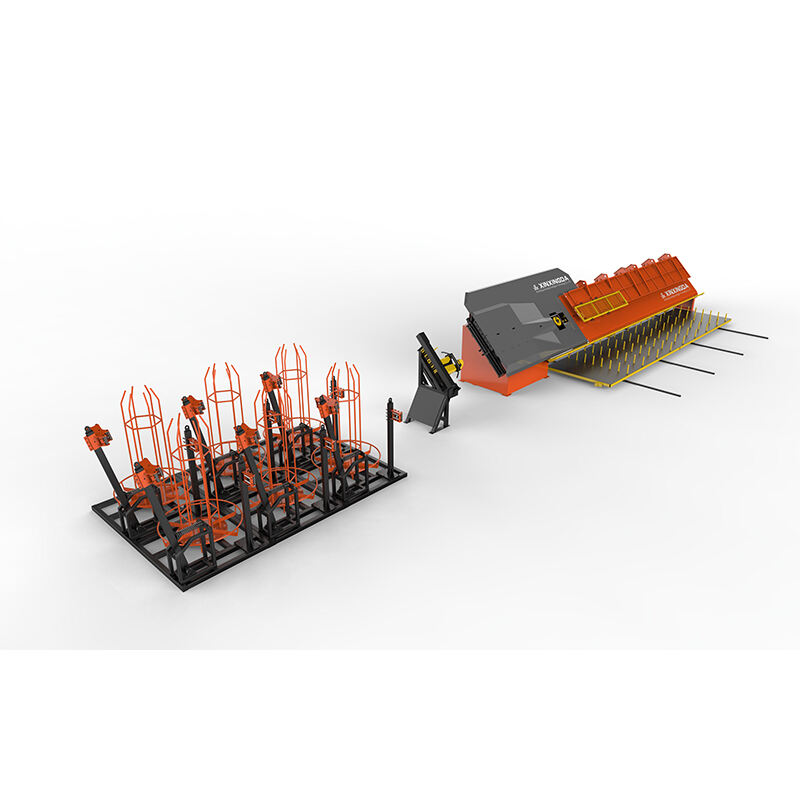

Transforming Construction Industry Through Advanced Metal Forming Technology

The construction landscape is rapidly evolving, and at the heart of this transformation lies the large-scale bending machine. These sophisticated pieces of equipment have revolutionized how builders approach metal forming projects, offering unprecedented efficiency and precision. As construction demands grow more complex, the role of advanced bending machinery becomes increasingly critical in meeting modern building requirements.

Today's construction projects require versatility, accuracy, and speed - attributes that large-scale bending machines deliver consistently. From crafting intricate architectural elements to forming robust structural components, these machines have become indispensable tools in the builder's arsenal. The impact of this technology extends far beyond simple metal forming, influencing project timelines, cost efficiency, and overall construction quality.

Enhanced Productivity and Efficiency Benefits

Accelerated Production Capabilities

The large-scale bending machine dramatically reduces the time required for metal forming operations. What once took days of manual labor can now be accomplished in hours, significantly accelerating project timelines. These machines can process multiple pieces simultaneously, maintaining consistent quality across all components.

Advanced automation features enable continuous operation with minimal operator intervention, allowing construction teams to focus on other critical tasks. The increased throughput translates directly into faster project completion times and improved resource utilization.

Precision and Quality Control

Modern large-scale bending machines incorporate sophisticated control systems that ensure unprecedented accuracy in metal forming. Computer-controlled operations eliminate human error, producing identical components with exact specifications every time. This level of precision is particularly valuable for projects requiring strict adherence to architectural designs and structural requirements.

Quality control becomes more manageable with automated systems that monitor and adjust bending parameters in real-time. The result is consistently high-quality output that meets or exceeds industry standards, reducing material waste and rework requirements.

Cost-Effective Solutions for Construction Projects

Reduced Labor Requirements

By automating complex bending operations, the large-scale bending machine significantly reduces labor costs. A single operator can manage the entire bending process, replacing what would traditionally require multiple skilled workers. This reduction in labor requirements not only decreases direct costs but also minimizes the risks associated with manual handling and worker fatigue.

The consistency and reliability of automated systems also reduce the need for specialized training and supervision, further contributing to cost savings. Construction companies can allocate their workforce more efficiently, focusing human resources on tasks that require creative problem-solving and strategic planning.

Material Optimization and Waste Reduction

Advanced bending machines incorporate sophisticated nesting and optimization algorithms that maximize material usage. These systems calculate the most efficient way to process metal sheets, minimizing waste and reducing material costs. The precision of automated bending also means fewer mistakes and rejected pieces, contributing to overall cost efficiency.

The ability to process various material types and thicknesses with the same machine adds another layer of cost-effectiveness. Construction companies can handle diverse project requirements without investing in multiple specialized tools or outsourcing certain operations.

Versatility in Application and Design

Diverse Material Processing Capabilities

The large-scale bending machine demonstrates remarkable versatility in handling different materials and thicknesses. From thin sheet metal to heavy-gauge steel, these machines can process a wide range of materials while maintaining precise control over the bending process. This flexibility allows construction companies to tackle diverse projects without changing equipment or tooling.

Advanced machines often feature quick-change tooling systems that facilitate rapid transitions between different material types and bending profiles. This adaptability helps construction teams respond quickly to changing project requirements and take on more varied work.

Complex Design Implementation

Modern large-scale bending machines excel at creating complex geometries and shapes that would be difficult or impossible to achieve through manual methods. The sophisticated control systems can execute intricate bending sequences, producing components with multiple angles and curves while maintaining tight tolerances.

This capability opens new possibilities for architectural design, allowing builders to realize innovative concepts that push the boundaries of traditional construction. The precision and repeatability of automated bending ensure that even the most complex designs can be reproduced consistently across large production runs.

Frequently Asked Questions

How does a large-scale bending machine improve construction safety?

Large-scale bending machines enhance workplace safety by eliminating many manual handling risks associated with traditional metal forming. Automated operations reduce worker exposure to heavy materials and dangerous machinery, while advanced safety features and emergency stops protect operators during operation.

What maintenance is required for optimal machine performance?

Regular maintenance includes daily inspections of hydraulic systems, lubrication of moving parts, calibration checks, and cleaning of sensors and control components. Following manufacturer-recommended maintenance schedules ensures reliable operation and extends machine life while maintaining precision and efficiency.

Can large-scale bending machines handle custom projects?

Modern large-scale bending machines are highly adaptable to custom projects through programmable controls and adjustable parameters. They can store multiple project profiles, making it easy to switch between different specifications and accommodate unique design requirements while maintaining consistency and quality.