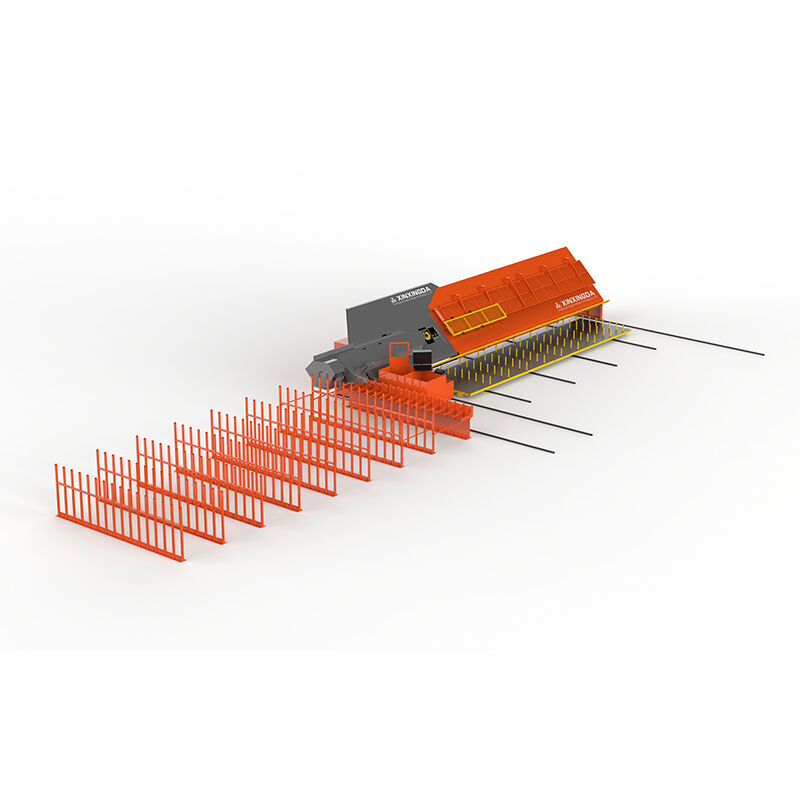

Manufacturing precision in steel processing has become increasingly critical as industries demand higher quality standards and tighter tolerances. CNC steel bar lines represent a significant advancement in automated steel processing technology, offering manufacturers the ability to achieve exceptional shearing accuracy while maintaining consistent production rates. These sophisticated systems integrate computer numerical control with advanced cutting mechanisms to deliver precise results that manual operations simply cannot match. The implementation of CNC steel bar lines in manufacturing facilities has revolutionized how steel bars are processed, cut, and prepared for various industrial applications.

Understanding CNC Steel Bar Line Technology

Core Components and Functionality

CNC steel bar lines incorporate several critical components that work together to achieve superior shearing accuracy. The control system serves as the brain of the operation, utilizing sophisticated algorithms to calculate precise cutting positions and timing. Servo motors provide the mechanical power needed for smooth, controlled movements throughout the cutting process. High-precision encoders continuously monitor position and speed, ensuring that every cut meets specified tolerances. The cutting mechanism itself features hardened steel blades designed to maintain sharpness over extended periods, while hydraulic systems deliver consistent pressure for clean cuts.

The integration of these components creates a seamless workflow that minimizes human error and maximizes precision. Advanced sensors monitor material positioning and automatically adjust cutting parameters based on real-time feedback. This closed-loop control system ensures that CNC steel bar lines maintain accuracy throughout extended production runs, even when processing materials with varying hardness or dimensional characteristics.

Automation and Control Systems

Modern CNC steel bar lines feature sophisticated automation systems that handle material feeding, positioning, and cutting operations with minimal human intervention. Programmable logic controllers coordinate all aspects of the cutting process, from initial material loading to final part ejection. Operators can input cutting specifications through intuitive touchscreen interfaces, allowing for quick setup changes between different production runs. The system stores cutting programs for frequently produced parts, enabling rapid transitions and reducing setup time.

Advanced diagnostic capabilities built into these systems continuously monitor performance parameters and alert operators to potential issues before they affect production quality. Predictive maintenance algorithms analyze cutting force, vibration patterns, and other operational data to schedule maintenance activities at optimal intervals, preventing unexpected downtime and maintaining consistent accuracy levels.

Factors Affecting Shearing Accuracy

Material Properties and Preparation

The accuracy of CNC steel bar lines depends significantly on proper material preparation and understanding of steel properties. Material hardness variations can affect cutting forces and blade wear patterns, potentially leading to dimensional inconsistencies if not properly managed. Surface conditions, including scale, rust, or coating materials, can interfere with cutting blade performance and result in rough or imprecise cuts. Proper material cleaning and preparation protocols ensure optimal cutting conditions and maintain the high precision capabilities of CNC steel bar lines.

Temperature effects also play a crucial role in shearing accuracy. Steel expands and contracts with temperature changes, which can affect final part dimensions if not accounted for in the cutting program. Advanced systems incorporate temperature compensation algorithms that adjust cutting positions based on ambient conditions and material temperature, maintaining accuracy across varying environmental conditions.

Machine Calibration and Maintenance

Regular calibration procedures are essential for maintaining the precision capabilities of CNC steel bar lines. Geometric accuracy checks verify that cutting mechanisms maintain proper alignment and positioning throughout their range of motion. Backlash measurements ensure that mechanical components operate within specified tolerances, preventing cumulative errors that could affect cutting accuracy. Blade condition monitoring programs track wear patterns and replacement schedules to maintain consistent cutting quality.

Preventive maintenance schedules address lubrication requirements, hydraulic system pressure checks, and electrical connection inspections. These routine activities prevent gradual degradation of system accuracy and extend the operational life of critical components. Proper maintenance documentation helps identify trends in component wear and performance, enabling proactive replacement strategies that minimize production disruptions.

Optimization Strategies for Enhanced Precision

Cutting Parameter Selection

Optimizing cutting parameters is crucial for maximizing the accuracy potential of CNC steel bar lines. Cutting speed selection must balance production efficiency with cut quality requirements. Higher speeds can reduce cycle times but may introduce vibrations or heat effects that compromise precision. Feed rates determine how quickly material advances through the cutting zone, affecting both surface finish and dimensional accuracy. Proper selection of these parameters requires understanding the relationship between material properties, tooling characteristics, and desired outcomes.

Blade clearance settings significantly impact cut quality and accuracy. Insufficient clearance can cause material deformation during cutting, while excessive clearance may result in burr formation or dimensional variations. CNC steel bar lines allow precise adjustment of these parameters through programmable controls, enabling optimization for specific material grades and cutting requirements.

Quality Control Integration

Implementing comprehensive quality control measures enhances the accuracy performance of CNC steel bar lines. In-process measurement systems can verify cut lengths and angles during production, providing immediate feedback for process adjustments. Statistical process control methods track dimensional variations over time, identifying trends that may indicate developing issues with cutting accuracy. Automated inspection systems reduce reliance on manual measurements and provide consistent, objective quality assessments.

Documentation and traceability systems record cutting parameters, material specifications, and quality measurements for each production lot. This information enables rapid identification of process changes that affect accuracy and supports continuous improvement initiatives. Integration with enterprise resource planning systems provides real-time visibility into production quality metrics and enables proactive management of accuracy-related issues.

Advanced Features for Superior Performance

Adaptive Control Systems

Modern CNC steel bar lines incorporate adaptive control technologies that automatically adjust cutting parameters based on real-time process feedback. Force sensors monitor cutting loads and adjust feed rates or cutting speeds to maintain optimal conditions throughout the cut. Vibration monitoring systems detect resonant frequencies and implement damping strategies to minimize their impact on cutting accuracy. These adaptive features enable consistent performance across varying material conditions and production requirements.

Machine learning algorithms analyze historical cutting data to identify optimal parameter combinations for specific material types and part geometries. This accumulated knowledge improves system performance over time and reduces the expertise required for optimal setup. Predictive models can anticipate accuracy issues before they occur, enabling proactive adjustments that maintain consistent quality levels.

Integration with Manufacturing Systems

Effective integration of CNC steel bar lines with broader manufacturing systems enhances overall production efficiency and accuracy. Communication protocols enable seamless data exchange between cutting systems and upstream processes, ensuring that material specifications and cutting requirements are properly coordinated. Integration with inventory management systems provides real-time visibility into material availability and production scheduling requirements.

Centralized monitoring systems aggregate performance data from multiple CNC steel bar lines, enabling facility-wide optimization of cutting operations. This comprehensive visibility supports data-driven decision making and identifies opportunities for process improvements that enhance accuracy across the entire production facility.

Troubleshooting Common Accuracy Issues

Dimensional Variation Problems

Addressing dimensional variations in CNC steel bar lines requires systematic investigation of potential causes and implementation of corrective measures. Inconsistent material properties can cause variations in cutting behavior, leading to dimensional inconsistencies between parts. Material suppliers should provide detailed specifications and certificates of analysis to enable proper cutting parameter selection. Regular incoming inspection procedures verify that materials meet specified requirements before processing.

Mechanical wear in cutting mechanisms can gradually affect accuracy over extended periods. Systematic measurement of critical dimensions throughout production runs helps identify developing issues before they exceed acceptable tolerances. Replacement schedules for wear components should be based on actual usage patterns and performance data rather than arbitrary time intervals.

Surface Quality Optimization

Poor surface quality on cut ends can indicate accuracy issues or improper cutting conditions in CNC steel bar lines. Burr formation typically results from dull cutting blades or inappropriate clearance settings. Regular blade inspection programs should monitor edge condition and implement replacement schedules that maintain optimal cutting performance. Proper blade selection for specific material grades ensures compatibility and optimal cutting results.

Cut surface roughness can affect subsequent processing operations and final part quality. Optimization of cutting parameters, including speed and feed rates, can significantly improve surface finish while maintaining dimensional accuracy. Post-cutting operations such as deburring or surface treatment may be necessary for applications requiring exceptional surface quality.

FAQ

What factors most significantly impact the accuracy of CNC steel bar lines

The most critical factors affecting accuracy include proper machine calibration, appropriate cutting parameter selection, material preparation quality, and regular maintenance of cutting tools. Environmental conditions such as temperature and vibration can also influence precision, making proper installation and climate control important considerations for optimal performance.

How often should CNC steel bar lines be calibrated for optimal accuracy

Calibration frequency depends on production volume and accuracy requirements, but most facilities perform basic accuracy checks weekly and comprehensive calibrations monthly. High-volume operations or applications requiring exceptional precision may require more frequent calibration intervals. Monitoring cut quality and dimensional measurements helps determine the optimal calibration schedule for specific applications.

Can CNC steel bar lines maintain accuracy when processing different steel grades

Yes, CNC steel bar lines can maintain accuracy across different steel grades through proper parameter adjustment and material-specific cutting programs. Different grades may require unique cutting speeds, feed rates, and blade clearances to achieve optimal results. Advanced systems can automatically adjust parameters based on material identification or operator input, ensuring consistent accuracy regardless of material variations.

What maintenance practices are essential for preserving cutting accuracy

Essential maintenance practices include regular blade inspection and replacement, hydraulic system pressure checks, lubrication of moving components, and verification of dimensional accuracy through test cuts. Preventive maintenance schedules should address all critical components that affect cutting precision, including encoders, servo motors, and mechanical guides. Proper documentation of maintenance activities helps identify patterns and optimize replacement intervals.

Table of Contents

- Understanding CNC Steel Bar Line Technology

- Factors Affecting Shearing Accuracy

- Optimization Strategies for Enhanced Precision

- Advanced Features for Superior Performance

- Troubleshooting Common Accuracy Issues

-

FAQ

- What factors most significantly impact the accuracy of CNC steel bar lines

- How often should CNC steel bar lines be calibrated for optimal accuracy

- Can CNC steel bar lines maintain accuracy when processing different steel grades

- What maintenance practices are essential for preserving cutting accuracy