The global energy sector continues to evolve rapidly, demanding increasingly sophisticated and reliable oil drilling equipment to meet growing extraction challenges. Modern petroleum exploration requires cutting-edge technology that can operate efficiently in diverse geological conditions while maintaining the highest safety standards. Advanced oil drilling equipment has revolutionized how energy companies approach exploration projects, enabling access to previously unreachable reserves and optimizing operational efficiency across drilling operations worldwide.

Contemporary drilling operations rely heavily on integrated systems that combine mechanical precision with digital monitoring capabilities. The evolution of oil drilling equipment has transformed from basic rotary systems to sophisticated automated platforms capable of real-time data analysis and predictive maintenance protocols. These technological advances enable operators to make informed decisions quickly, reducing downtime and maximizing resource extraction efficiency.

Industry professionals recognize that selecting appropriate oil drilling equipment directly impacts project success rates and long-term profitability. Modern exploration companies must consider various factors including geological conditions, environmental regulations, operational budgets, and technological compatibility when investing in drilling infrastructure. The strategic deployment of advanced equipment solutions has become essential for maintaining competitive advantages in today's demanding energy marketplace.

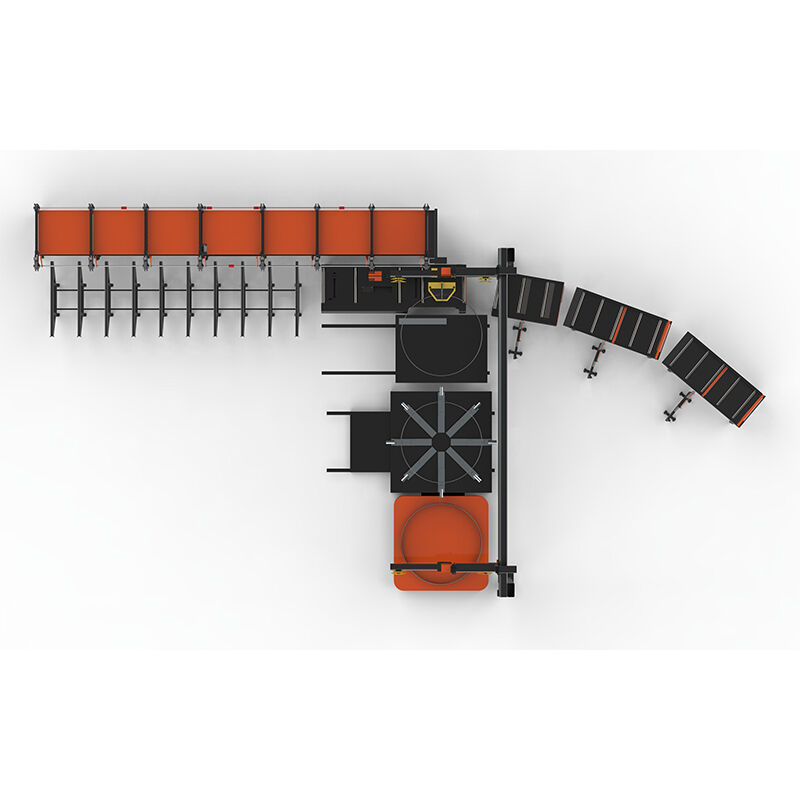

Core Components of Modern Drilling Systems

Rotary Table and Drive Systems

The rotary table serves as the foundational component of most oil drilling equipment configurations, providing the primary rotation mechanism for drilling operations. Advanced rotary systems incorporate variable speed controls and torque management features that allow operators to adjust drilling parameters based on specific geological formations. Modern drive systems utilize high-efficiency motors and precision gearing to deliver consistent power transmission while minimizing energy consumption and mechanical wear.

Contemporary rotary table designs integrate sophisticated bearing systems and lubrication mechanisms that extend operational lifespans significantly compared to traditional alternatives. These improvements enable continuous operation under demanding conditions while reducing maintenance requirements and associated operational costs. The integration of digital monitoring systems allows real-time assessment of rotary performance, enabling predictive maintenance scheduling and optimizing equipment utilization rates.

Mud Circulation and Filtration Systems

Effective mud circulation represents a critical aspect of successful drilling operations, requiring specialized oil drilling equipment designed for fluid management and contamination control. Modern circulation systems incorporate multi-stage filtration processes that remove drill cuttings and maintain optimal mud properties throughout drilling cycles. Advanced pumping systems deliver precise flow rates and pressure controls necessary for efficient hole cleaning and formation stability.

Sophisticated mud systems feature automated mixing capabilities and chemical injection systems that maintain consistent fluid properties as drilling progresses through different geological layers. These systems integrate seamlessly with other oil drilling equipment components, providing comprehensive fluid management solutions that enhance drilling efficiency and reduce environmental impact. Real-time monitoring of mud properties enables operators to make immediate adjustments, preventing costly drilling complications and ensuring optimal wellbore conditions.

Advanced Automation and Control Technologies

Digital Monitoring and Data Analytics

Modern oil drilling equipment incorporates comprehensive digital monitoring systems that collect and analyze thousands of operational parameters continuously during drilling operations. These sophisticated platforms utilize advanced sensors and data acquisition systems to monitor equipment performance, geological conditions, and operational efficiency metrics in real-time. The integration of machine learning algorithms enables predictive analytics that identify potential equipment failures before they occur, significantly reducing unplanned downtime.

Data analytics platforms associated with contemporary drilling equipment provide operators with actionable insights that optimize drilling parameters and improve overall operational efficiency. These systems can automatically adjust drilling parameters based on real-time geological feedback, ensuring optimal penetration rates while maintaining wellbore stability. The ability to access and analyze drilling data remotely enables expert consultation and support regardless of drilling location, enhancing operational decision-making capabilities.

Automated Safety and Emergency Response Systems

Safety remains paramount in drilling operations, driving the development of sophisticated automated safety systems integrated into modern oil drilling equipment. Advanced blowout prevention systems incorporate multiple redundant safety mechanisms and automated shutdown protocols that respond instantly to dangerous pressure conditions. These systems continuously monitor wellbore pressure and fluid returns, automatically implementing emergency procedures when predetermined safety thresholds are exceeded.

Contemporary safety systems extend beyond traditional blowout prevention to include comprehensive personnel protection and equipment safeguarding mechanisms. Automated fire suppression systems, gas detection networks, and emergency shutdown protocols work together to create comprehensive safety environments around drilling operations. The integration of these safety systems with primary oil drilling equipment ensures seamless operation while maintaining the highest safety standards throughout all phases of drilling operations.

Specialized Equipment for Challenging Environments

Deep Water and Offshore Applications

Offshore drilling operations present unique challenges that require specialized oil drilling equipment designed to withstand marine environments and extreme operating conditions. Advanced offshore platforms incorporate dynamic positioning systems and motion compensation technologies that maintain drilling accuracy despite wave action and vessel movement. These sophisticated systems enable precise drilling operations in water depths exceeding several thousand feet while maintaining operational efficiency and safety standards.

Deepwater drilling equipment features enhanced corrosion resistance and specialized sealing systems designed to operate reliably in harsh marine environments. Advanced materials and coating technologies protect critical components from saltwater exposure and extreme pressure conditions encountered during deepwater operations. The integration of subsea control systems enables remote operation of critical equipment components, reducing personnel exposure to hazardous conditions while maintaining operational control.

High-Temperature and High-Pressure Applications

Extreme downhole conditions require specialized oil drilling equipment capable of operating reliably under high-temperature and high-pressure environments commonly encountered in deep formations. Advanced metallurgy and engineering techniques enable equipment components to maintain structural integrity and operational performance under extreme thermal and pressure stresses. Specialized cooling systems and thermal management technologies protect sensitive electronic components and ensure reliable operation in challenging thermal environments.

High-pressure drilling operations utilize specialized pressure control equipment and reinforced system components designed to handle extreme pressure differentials safely. Advanced pressure monitoring systems provide continuous assessment of downhole conditions, enabling operators to maintain optimal drilling parameters while preventing dangerous pressure excursions. The development of specialized drilling fluids and chemical systems supports high-pressure operations by maintaining wellbore stability and equipment protection under extreme conditions.

Maintenance and Operational Optimization

Predictive Maintenance Strategies

Effective maintenance programs represent essential components of successful oil drilling equipment operations, directly impacting operational efficiency and equipment longevity. Modern predictive maintenance approaches utilize advanced diagnostic tools and condition monitoring systems to assess equipment health continuously and identify potential failure modes before they impact operations. Vibration analysis, thermal imaging, and oil analysis programs provide comprehensive insights into equipment condition and performance trends.

Advanced maintenance management systems integrate with drilling equipment control platforms to provide comprehensive maintenance scheduling and resource planning capabilities. These systems track component usage, operational hours, and performance metrics to optimize maintenance intervals and reduce unnecessary service activities. The implementation of condition-based maintenance protocols enables operators to maximize equipment availability while minimizing maintenance costs and operational disruptions.

Performance Optimization and Efficiency Enhancement

Continuous performance optimization represents a critical aspect of modern oil drilling equipment operations, requiring systematic analysis of operational data and equipment performance metrics. Advanced optimization algorithms analyze drilling parameters, equipment performance, and geological conditions to identify opportunities for efficiency improvements and cost reductions. These systems can automatically adjust drilling parameters to optimize penetration rates while maintaining wellbore quality and equipment protection.

Comprehensive performance monitoring systems track key operational metrics including drilling rates, equipment utilization, energy consumption, and maintenance requirements. This data enables operators to identify trends and optimize drilling programs for maximum efficiency and cost-effectiveness. The integration of performance optimization tools with oil drilling equipment control systems enables real-time adjustments that maximize operational efficiency while maintaining safety and quality standards.

Environmental Considerations and Sustainability

Emission Control and Environmental Protection

Environmental stewardship has become increasingly important in drilling operations, driving the development of advanced oil drilling equipment that minimizes environmental impact while maintaining operational efficiency. Modern drilling systems incorporate sophisticated emission control technologies and waste management systems that reduce environmental footprints significantly compared to traditional approaches. Advanced filtration and treatment systems ensure that drilling operations comply with increasingly stringent environmental regulations.

Sustainable drilling practices require oil drilling equipment that optimizes resource utilization and minimizes waste generation throughout drilling operations. Advanced recycling systems and closed-loop fluid management technologies reduce waste disposal requirements while maintaining operational efficiency. The implementation of renewable energy sources and energy-efficient equipment designs further reduces the environmental impact of drilling operations while supporting industry sustainability goals.

Noise Reduction and Community Impact Mitigation

Community relations and noise control have become important considerations in drilling operations, particularly in populated areas where traditional oil drilling equipment noise levels may impact local communities. Advanced sound dampening technologies and equipment design modifications significantly reduce operational noise levels while maintaining drilling performance and efficiency. Specialized enclosure systems and acoustic barriers provide additional noise control measures for sensitive locations.

Modern drilling equipment designs incorporate advanced materials and engineering techniques that minimize noise generation at the source while optimizing operational performance. Variable speed controls and advanced motor technologies enable operators to adjust equipment operation to minimize noise impact during sensitive periods. The development of quieter drilling technologies supports industry efforts to maintain positive community relationships while conducting necessary energy exploration activities.

FAQ

What factors should be considered when selecting oil drilling equipment for specific projects

Selecting appropriate oil drilling equipment requires careful consideration of geological conditions, drilling depth requirements, environmental regulations, and operational budgets. Project-specific factors including formation hardness, pressure conditions, and drilling objectives directly influence equipment selection decisions. Additionally, operator experience, maintenance capabilities, and local support infrastructure should be evaluated to ensure successful project execution and long-term operational efficiency.

How do modern safety systems enhance drilling operation security

Contemporary oil drilling equipment incorporates multiple layers of automated safety systems that continuously monitor operational parameters and implement emergency procedures when necessary. Advanced blowout prevention systems, gas detection networks, and automated shutdown protocols work together to create comprehensive safety environments. These systems utilize real-time monitoring and predictive analytics to identify potential hazards before they develop into dangerous situations, significantly enhancing personnel safety and environmental protection.

What role does digitalization play in modern drilling operations

Digital technologies have transformed oil drilling equipment operations by enabling real-time monitoring, predictive maintenance, and automated optimization of drilling parameters. Advanced data analytics platforms process thousands of operational parameters continuously, providing operators with actionable insights that improve efficiency and reduce costs. Remote monitoring capabilities allow expert consultation and support regardless of drilling location, enhancing decision-making and operational performance throughout drilling projects.

How do environmental considerations impact drilling equipment selection

Environmental regulations and sustainability goals increasingly influence oil drilling equipment selection and operational practices. Modern equipment designs incorporate emission control technologies, waste reduction systems, and energy-efficient components that minimize environmental impact while maintaining operational performance. Compliance with environmental regulations requires careful selection of equipment technologies and operational procedures that support both drilling objectives and environmental stewardship responsibilities.