The construction industry continuously seeks innovative solutions to enhance productivity and streamline operations. Among the most transformative technologies emerging in reinforcement fabrication is the steel cage rolling welding machine, a sophisticated piece of equipment that revolutionizes how construction teams approach rebar cage production. This advanced machinery addresses the growing demand for faster, more precise, and cost-effective methods of creating reinforced concrete structures. Modern construction projects require exceptional speed and accuracy, making traditional manual welding methods increasingly inadequate for meeting tight deadlines and quality standards.

Understanding Steel Cage Rolling Welding Technology

Core Components and Mechanical Design

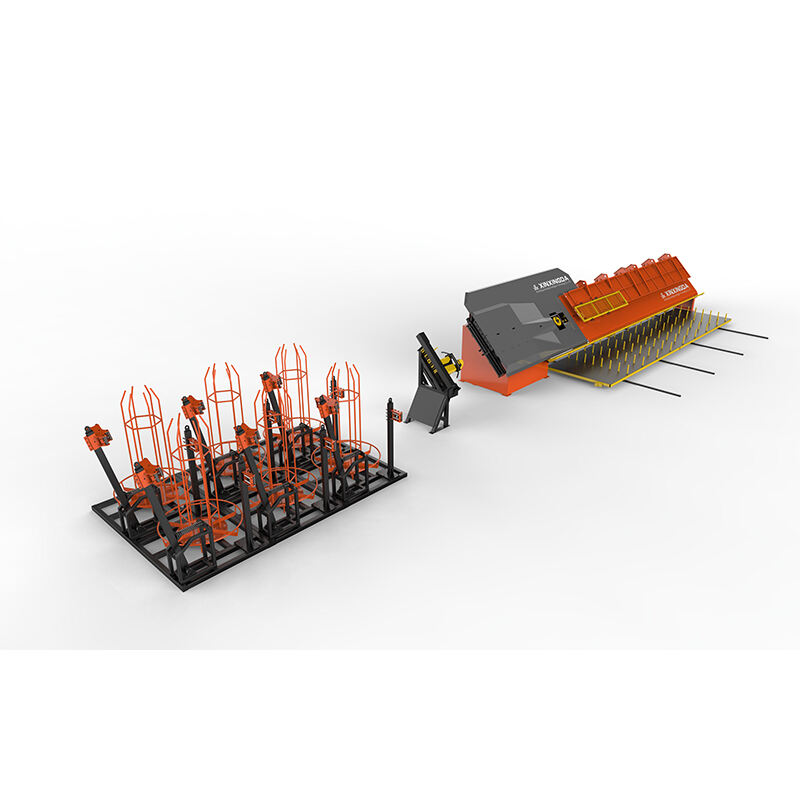

The steel cage rolling welding machine incorporates multiple precision-engineered components that work in seamless coordination to produce high-quality reinforcement cages. The primary rolling mechanism consists of adjustable forming wheels that guide steel bars into precise circular or rectangular configurations while maintaining consistent spacing between longitudinal reinforcement bars. Advanced servo motors control the rotation speed and positioning accuracy, ensuring uniform cage dimensions throughout the production process. The welding system typically employs resistance welding technology, delivering consistent heat application at predetermined intervals to create strong, reliable joints between intersecting bars.

Sophisticated control systems integrate programmable logic controllers with user-friendly interfaces, allowing operators to input specific cage dimensions, bar spacing requirements, and welding parameters. These machines often feature automatic wire feeding mechanisms that continuously supply stirrup material, eliminating manual handling and reducing production interruptions. The robust frame construction provides stability during high-speed operations while accommodating various bar diameters and cage sizes commonly used in construction applications.

Operational Workflow and Process Integration

The operational sequence begins with loading longitudinal reinforcement bars into the machine's holding fixtures, followed by programming the desired cage specifications through the digital control panel. Once initiated, the machine automatically positions the bars according to engineering drawings while the rolling mechanism begins forming the cage structure. The integrated welding system activates at predetermined points, creating secure connections between stirrups and main reinforcement bars without requiring operator intervention for each weld point.

Quality monitoring systems continuously track welding parameters, cage dimensions, and production rates, providing real-time feedback to ensure consistent output quality. Many modern machines incorporate automatic measurement systems that verify cage dimensions against programmed specifications, reducing the likelihood of dimensional errors that could compromise structural integrity. The entire process operates with minimal manual intervention, allowing skilled technicians to focus on quality control and machine optimization rather than repetitive manual tasks.

Productivity Enhancement Through Automation

Speed and Volume Improvements

Traditional manual cage fabrication typically requires multiple workers several hours to complete a single large reinforcement cage, whereas automated steel cage rolling welding machines can produce equivalent structures in a fraction of the time. Production rates can increase by 300-500% compared to conventional methods, enabling construction teams to meet aggressive project schedules while maintaining consistent quality standards. The continuous operation capability allows for extended production runs with minimal downtime, maximizing equipment utilization and overall project efficiency.

The high-speed welding process ensures rapid joint formation while maintaining optimal penetration and strength characteristics. Automated material handling systems reduce the time required for cage positioning and orientation, eliminating much of the manual labor traditionally associated with reinforcement preparation. This increased production capacity enables contractors to take on larger projects or complete existing work ahead of schedule, providing competitive advantages in bidding processes and client satisfaction.

Labor Optimization and Skill Enhancement

The implementation of steel cage rolling welding machines significantly transforms workforce requirements, shifting emphasis from physical labor to technical operation and quality oversight. Fewer personnel are required for cage production, allowing companies to reallocate human resources to other critical project activities while reducing overall labor costs. The remaining operators develop advanced technical skills in machine programming, maintenance, and quality control, creating more valuable and specialized positions within the organization.

Training requirements for machine operation are typically shorter than developing traditional welding expertise, enabling companies to quickly establish competent operational teams. The reduced physical demands associated with automated production decrease worker fatigue and injury risks, contributing to improved workplace safety and reduced workers' compensation costs. This optimization of human resources allows construction companies to maintain consistent production capabilities even when facing skilled labor shortages that commonly affect the industry.

Quality and Precision Advantages

Dimensional Accuracy and Consistency

Automated steel cage rolling welding machines deliver exceptional dimensional precision that surpasses manual fabrication methods by significant margins. Computer-controlled positioning systems ensure that reinforcement bar spacing remains consistent throughout the entire cage structure, eliminating the variations that commonly occur with manual measurement and placement. The precision forming wheels maintain exact cage diameters or dimensions according to programmed specifications, reducing the need for post-production adjustments or corrections.

Quality control systems continuously monitor production parameters and can detect deviations from specified tolerances in real-time, automatically adjusting machine settings to maintain compliance with engineering requirements. This level of precision is particularly crucial for precast concrete applications where dimensional accuracy directly impacts assembly efficiency and structural performance. The consistent quality output reduces material waste and rework costs while ensuring compliance with stringent construction standards and building codes.

Weld Quality and Structural Integrity

The controlled welding environment provided by steel cage rolling welding machine systems ensures optimal joint formation with consistent penetration depth and strength characteristics. Automated welding parameters eliminate human variability factors that can affect weld quality, such as inconsistent electrode positioning, variable welding speed, or fluctuating current settings. The result is superior joint integrity that meets or exceeds structural engineering requirements for reinforced concrete applications.

Advanced welding monitoring systems track electrode condition, current flow, and welding time for each joint, maintaining detailed production records that support quality assurance programs. The absence of manual welding reduces the potential for defects such as incomplete fusion, porosity, or inconsistent penetration that can compromise structural performance. This enhanced weld quality contributes to improved long-term durability of reinforced concrete structures while reducing the need for costly repairs or structural modifications.

Economic Impact and Cost Effectiveness

Direct Cost Savings and ROI Analysis

The initial investment in steel cage rolling welding machine technology typically generates substantial returns through multiple cost reduction mechanisms. Labor cost savings represent the most immediate benefit, as automated production requires significantly fewer personnel while achieving higher output rates. Material waste reduction occurs through precise cutting and positioning systems that minimize scrap generation and optimize raw material utilization throughout the production process.

Energy efficiency improvements result from optimized welding cycles and reduced overall production time compared to traditional methods. The elimination of rework and quality-related delays reduces project costs while improving schedule adherence. Most contractors experience complete ROI within 12-24 months of implementation, depending on production volume and project complexity. The long-term financial benefits extend beyond initial cost recovery, providing ongoing competitive advantages through enhanced bidding capabilities and improved profit margins.

Market Competitiveness and Business Growth

Companies utilizing advanced steel cage rolling welding machines gain significant competitive advantages in project bidding through their ability to offer faster delivery times and more competitive pricing structures. The enhanced production capacity enables contractors to pursue larger projects or handle multiple concurrent jobs that would be impossible with traditional fabrication methods. This expanded capability often leads to increased market share and business growth opportunities within the construction industry.

The superior quality and consistency of machine-produced cages enhance company reputation and client satisfaction, leading to repeat business and referral opportunities. The ability to meet tight project deadlines consistently builds trust with general contractors and project owners, creating long-term business relationships that provide sustainable revenue streams. These competitive advantages become increasingly important as the construction industry continues evolving toward greater efficiency and quality standards.

Implementation Considerations and Best Practices

Site Planning and Installation Requirements

Successful implementation of steel cage rolling welding machine systems requires careful consideration of facility requirements, including adequate floor space for machine installation and cage handling operations. Power supply specifications must meet the demanding requirements of high-current welding systems, typically requiring dedicated electrical service and appropriate grounding systems. Ventilation systems should accommodate welding fume extraction to maintain safe working conditions and comply with occupational health regulations.

Material handling systems should be designed to efficiently supply raw materials to the machine while providing adequate space for finished cage storage and transportation. Crane or lifting equipment may be necessary for handling large cages, requiring appropriate structural support and clearance considerations. The layout should optimize workflow patterns to minimize material movement and maximize production efficiency while maintaining safe working conditions for all personnel.

Training and Maintenance Programs

Comprehensive operator training programs are essential for maximizing the benefits of steel cage rolling welding machine investments. Training should cover machine operation, programming procedures, quality control methods, and basic maintenance tasks to ensure optimal performance and longevity. Regular refresher training helps maintain operator competency while introducing new features or operational improvements as they become available.

Preventive maintenance programs significantly extend equipment life while minimizing unexpected downtime that could disrupt production schedules. These programs should include regular inspection schedules, lubrication procedures, and component replacement intervals based on manufacturer recommendations and actual operating conditions. Establishing relationships with qualified service technicians ensures rapid response for complex repairs while maintaining comprehensive maintenance records supports warranty compliance and equipment optimization efforts.

FAQ

What types of reinforcement cages can be produced with steel cage rolling welding machines

Steel cage rolling welding machines can produce a wide variety of reinforcement configurations including circular cages for columns and piles, rectangular cages for beams and footings, and custom shapes for specialized applications. Most machines accommodate bar diameters ranging from 6mm to 40mm with cage diameters from 200mm to 3000mm or more. The machines can handle various stirrup configurations including circular, square, rectangular, and polygonal shapes depending on structural requirements.

How much space is required for installing a steel cage rolling welding machine

Space requirements vary depending on machine size and cage dimensions but typically require a minimum area of 20-30 meters in length and 10-15 meters in width for larger machines. Additional space is needed for raw material storage, finished cage handling, and maintenance access. Ceiling height should accommodate the largest cage diameter plus adequate clearance for crane operations, usually requiring 6-8 meters minimum height for most applications.

What is the typical production capacity of automated steel cage welding systems

Production capacity depends on cage size, complexity, and welding requirements but most modern machines can produce 50-200 linear meters of cage per day operating at normal speeds. Large diameter cages typically require more time per unit length compared to smaller cages due to increased circumference and welding points. Continuous operation capabilities allow for extended production runs, potentially doubling output during peak demand periods or tight project schedules.

How does automated cage production compare to manual methods in terms of quality

Automated steel cage rolling welding machines consistently deliver superior quality compared to manual methods through precise dimensional control, consistent welding parameters, and elimination of human variability factors. Dimensional tolerances typically improve by 50-80% while weld quality remains consistent throughout production runs. The automated process reduces defects, minimizes rework requirements, and ensures compliance with structural engineering specifications and building code requirements for all produced cages.

Table of Contents

- Understanding Steel Cage Rolling Welding Technology

- Productivity Enhancement Through Automation

- Quality and Precision Advantages

- Economic Impact and Cost Effectiveness

- Implementation Considerations and Best Practices

-

FAQ

- What types of reinforcement cages can be produced with steel cage rolling welding machines

- How much space is required for installing a steel cage rolling welding machine

- What is the typical production capacity of automated steel cage welding systems

- How does automated cage production compare to manual methods in terms of quality