How to Select a Steel Cage Rolling Welding Machine for Construction

Role of a Steel Cage Rolling Welding Machine in Modern Projects

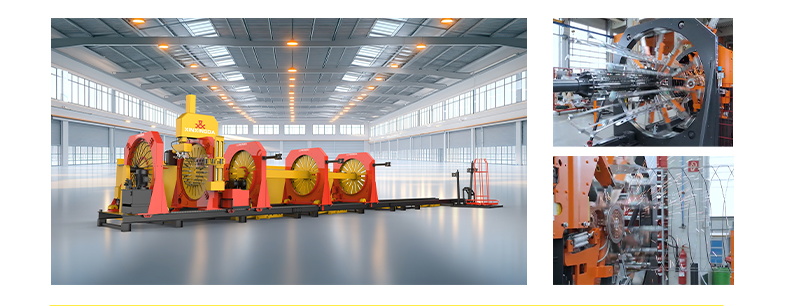

A steel cage rolling welding machine is a crucial piece of equipment for infrastructure and construction projects. It automates the process of producing reinforced steel cages used in foundations, bridges, tunnels, and large-scale concrete structures. By providing precise welding and consistent rolling, the machine not only saves labor but also ensures structural stability. For companies looking to boost productivity and reduce human error, choosing the right steel cage rolling welding machine can make a significant difference.

The importance of this machine lies in its ability to handle large volumes of reinforcement cages with uniform quality. Unlike manual welding, which requires more time and is prone to inconsistencies, a steel cage rolling welding machine guarantees accuracy in spacing, weld points, and alignment. When construction projects depend on tight deadlines and strict quality standards, the right selection of this equipment becomes a long-term investment in efficiency and safety.

Key Features of a Steel Cage Rolling Welding Machine

Structural Strength and Durability

The build quality of a steel cage rolling welding machine determines how well it performs under demanding conditions. Machines designed with high-grade steel frames and durable components last longer and deliver consistent performance. Durability also means fewer breakdowns and reduced downtime, which translates into better overall project efficiency.

Welding Precision and Control

Accuracy is essential in welding reinforcement cages. A steel cage rolling welding machine with advanced control systems ensures every weld point is strong and properly aligned. Precision welding not only improves the safety of the finished structure but also reduces the need for rework, saving both time and materials.

Operational Efficiency of Steel Cage Rolling Welding Machine

Automation and Productivity

Automation plays a vital role in the modern construction sector. A steel cage rolling welding machine with automated feeding and rolling systems can handle large projects faster while requiring fewer workers. Higher productivity means construction companies can complete projects within deadlines while maintaining consistent quality.

Energy Consumption and Cost Savings

Operating costs are an important consideration when selecting a steel cage rolling welding machine. Machines that are designed with energy-saving technology reduce power consumption without compromising performance. Lower energy usage not only saves costs but also supports sustainable construction practices.

Customization Options for Steel Cage Rolling Welding Machine

Adaptability to Project Needs

Every construction project has unique requirements. A steel cage rolling welding machine that offers flexibility in cage sizes, lengths, and diameters provides greater adaptability. The ability to adjust settings quickly helps contractors respond to different project demands efficiently.

Compatibility with Reinforcement Standards

Construction projects must adhere to strict reinforcement standards. A steel cage rolling welding machine that supports compliance with local and international specifications ensures cages meet quality and safety regulations. Compatibility with multiple standards gives companies more versatility across different project types.

Maintenance of Steel Cage Rolling Welding Machine

Routine Inspections and Adjustments

Like any large-scale equipment, a steel cage rolling welding machine requires regular inspection. Checking weld joints, rollers, and electronic components prevents issues from developing into costly breakdowns. Minor adjustments to alignment and tension can significantly extend machine life.

Replacement of Wear Parts

Even with proper care, certain components will eventually wear out. Timely replacement of consumables such as welding tips, rollers, and electrical contacts ensures the machine continues working efficiently. Planning ahead for part replacements avoids unexpected downtime during critical construction phases.

Safety Considerations for Steel Cage Rolling Welding Machine

Operator Training and Guidelines

Operating a steel cage rolling welding machine requires skilled personnel. Proper training ensures operators can handle controls effectively, follow safety protocols, and respond to emergencies quickly. A well-trained workforce minimizes accidents while extending machine longevity.

Workplace Safety and Environment

The operating environment influences how efficiently a steel cage rolling welding machine functions. Proper ventilation, organized workspace, and clear safety barriers reduce risks for operators. Creating an environment that prioritizes safety enhances both productivity and machine protection.

Long-Term Investment in Steel Cage Rolling Welding Machine

Cost-Benefit Analysis

While the initial purchase of a steel cage rolling welding machine may be significant, the long-term savings in labor, time, and material waste make it a worthwhile investment. Companies that prioritize high-quality machines benefit from lower repair costs and better project outcomes over time.

Partnering with Reliable Suppliers

Working with trusted suppliers ensures businesses receive not only the machine but also after-sales support, training, and spare parts availability. Reliable partnerships contribute to smoother operations and help companies stay ahead in competitive construction markets.

FAQ

What are the main advantages of using a steel cage rolling welding machine

The main advantages include increased productivity, consistent weld quality, reduced labor costs, and improved structural reliability in construction projects.

How often should a steel cage rolling welding machine undergo maintenance

Routine maintenance should be conducted daily for cleaning and inspections, with scheduled professional servicing at regular intervals depending on usage intensity.

Can a steel cage rolling welding machine handle different cage sizes

Yes, most machines are designed with adjustable settings to produce different cage diameters and lengths, making them versatile for various project needs.

Why is operator training important when using a steel cage rolling welding machine

Training ensures operators can manage the machine safely and efficiently, reducing risks of accidents while maintaining consistent production quality.

Table of Contents

- How to Select a Steel Cage Rolling Welding Machine for Construction

- Role of a Steel Cage Rolling Welding Machine in Modern Projects

- Key Features of a Steel Cage Rolling Welding Machine

- Operational Efficiency of Steel Cage Rolling Welding Machine

- Customization Options for Steel Cage Rolling Welding Machine

- Maintenance of Steel Cage Rolling Welding Machine

- Safety Considerations for Steel Cage Rolling Welding Machine

- Long-Term Investment in Steel Cage Rolling Welding Machine

-

FAQ

- What are the main advantages of using a steel cage rolling welding machine

- How often should a steel cage rolling welding machine undergo maintenance

- Can a steel cage rolling welding machine handle different cage sizes

- Why is operator training important when using a steel cage rolling welding machine