Importance of Maintaining a Large-Scale Bending Machine

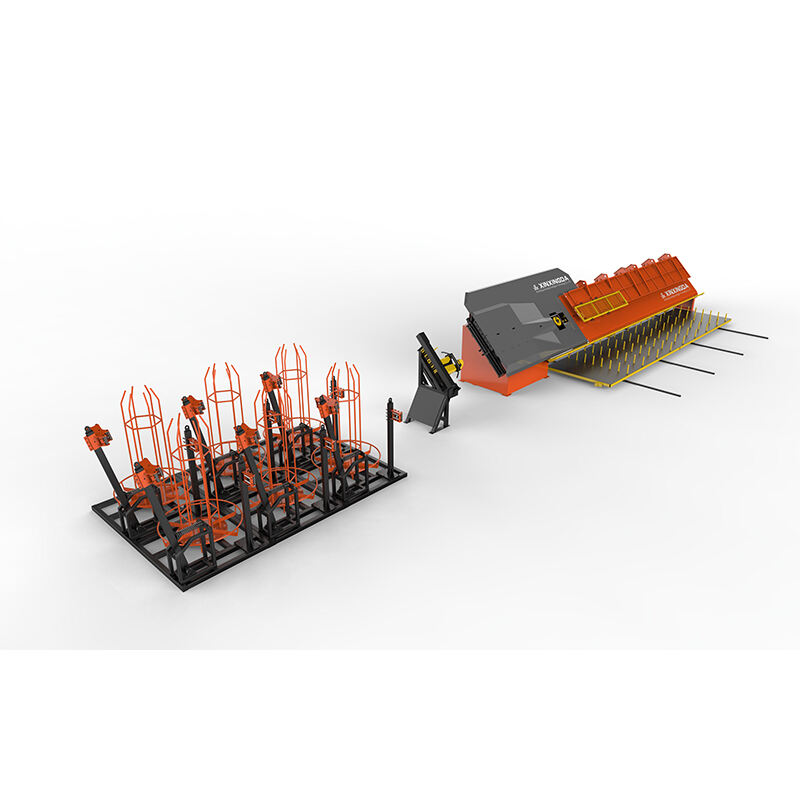

A large-scale bending machine is a critical piece of equipment in modern manufacturing. It plays an essential role in shaping metal sheets, pipes, and other materials with precision and efficiency. Whether used in construction, automotive, shipbuilding, or industrial production, the machine’s performance directly impacts productivity and overall costs. Extending the lifespan of a large-scale bending machine is not only about reducing breakdowns but also about improving long-term efficiency and achieving higher return on investment.

Regular care, proper operation, and preventive maintenance are vital steps to ensure the machine continues delivering reliable results. When businesses depend heavily on bending machines for high-volume tasks, ignoring maintenance could lead to downtime, expensive repairs, and even safety hazards. By investing in well-structured maintenance and training practices, companies can maximize machine performance while saving costs in the long run.

Daily Maintenance of Large-Scale Bending Machine

Cleaning Practices for Longevity

Keeping a large-scale bending machine clean may seem simple, but it has a significant impact on performance. Dust, debris, and leftover metal particles can build up over time, causing friction and wear on moving parts. Regular cleaning of the bending dies, rollers, and hydraulic systems ensures smooth operation. Operators should follow a daily routine that includes wiping down surfaces, checking for oil leaks, and removing material build-up before it interferes with accuracy.

Lubrication and Inspection

Lubrication is one of the most effective methods to extend the lifespan of a large-scale bending machine. Proper lubrication reduces friction, prevents corrosion, and enhances movement between mechanical parts. Regular inspection schedules should include checking the lubrication system, ensuring oil levels are maintained, and replacing old or contaminated lubricants. A consistent lubrication plan helps avoid unnecessary strain on the machine, prolonging its operational life.

Operational Guidelines for Large-Scale Bending Machine

Correct Usage of Controls

Operators play a crucial role in maintaining the efficiency of a large-scale bending machine. Misuse or rough handling of the controls can result in mechanical strain and premature damage. Training operators on how to use the control panel effectively ensures smoother operations and less risk of mechanical stress. Properly following bending procedures, such as setting the correct pressure and alignment, also safeguards both the machine and the final product.

Avoiding Overloading

Every large-scale bending machine has a designed capacity, and exceeding that limit can drastically shorten its lifespan. Overloading puts stress on the hydraulic system, rollers, and structural components, leading to cracks or breakdowns. Operators must understand machine specifications and avoid pushing the equipment beyond its capabilities. By respecting load limits and distributing tasks effectively, businesses can prevent unnecessary wear and prolong equipment usability.

Scheduled Maintenance of Large-Scale Bending Machine

Routine Checkups and Adjustments

Implementing scheduled maintenance is essential to keep a large-scale bending machine functioning at its best. Routine checkups include monitoring wear on parts, inspecting hydraulic hoses, and tightening loose connections. Adjustments to alignment and calibration ensure consistent bending results while reducing stress on components. Scheduled inspections can catch minor issues early before they develop into costly repairs.

Replacement of Worn Components

No matter how well a large-scale bending machine is maintained, certain parts will eventually wear out. Timely replacement of these components is necessary to prevent unexpected failures. Common replacements include seals, bearings, and hydraulic elements. Businesses that plan component replacement in advance minimize downtime and avoid emergency repair costs, ensuring smoother operations and extending the life of the machine.

Safety Practices in Operating Large-Scale Bending Machine

Operator Training and Safety Protocols

Safety and efficiency go hand in hand when operating a large-scale bending machine. Proper training ensures operators know how to handle the equipment correctly while following workplace safety protocols. This reduces the risk of accidents and protects the machine from operator error. Training should cover emergency stops, correct positioning of materials, and monitoring machine behavior for unusual vibrations or noises.

Workplace Environment and Protection

The environment in which a large-scale bending machine operates influences its performance. Maintaining proper temperature, ventilation, and workspace cleanliness helps the machine work under optimal conditions. Protective measures such as installing guards, using safety locks, and applying anti-vibration pads not only enhance operator safety but also reduce stress on the equipment itself.

Enhancing Efficiency of Large-Scale Bending Machine

Software and Control Upgrades

Modern large-scale bending machines often include computerized control systems. Updating software and control units can enhance precision, improve energy efficiency, and reduce operational strain. These upgrades allow businesses to handle more complex bending tasks while minimizing errors. By keeping technology up to date, companies can extend machine life and stay competitive in their industry.

Energy-Saving Techniques

Efficient energy use contributes to the overall sustainability of a large-scale bending machine. Operators can adopt energy-saving techniques, such as shutting down the machine during idle times and optimizing bending sequences to reduce unnecessary operations. Energy efficiency not only saves costs but also reduces machine strain, helping extend its operational lifespan.

Long-Term Investment in Large-Scale Bending Machine

Choosing Quality Parts and Accessories

Investing in high-quality parts and accessories for a large-scale bending machine is crucial for maintaining reliability. Low-quality components may seem cost-effective initially but can lead to breakdowns and performance issues. By using certified parts, businesses can protect the machine from premature wear and ensure consistent productivity.

Partnering with Reliable Service Providers

Working with trusted service providers ensures timely support and access to professional expertise. A reliable partner can offer tailored maintenance plans, quick response times, and expert guidance on extending machine lifespan. Companies that collaborate with experienced providers gain a competitive advantage by minimizing downtime and optimizing equipment performance.

FAQ

What is the best way to maintain a large-scale bending machine daily

Daily maintenance includes cleaning machine surfaces, checking for leaks, and ensuring all moving parts are properly lubricated. Consistent cleaning prevents debris buildup that can cause long-term damage.

How often should parts of a large-scale bending machine be replaced

Parts should be inspected regularly and replaced as soon as wear is identified. Common replacements include seals, bearings, and hydraulic elements, usually based on usage frequency.

Why is operator training important for a large-scale bending machine

Proper training ensures operators use the machine correctly, preventing misuse and reducing the risk of accidents. Skilled operators extend machine lifespan by handling it within safe operating limits.

Can upgrading software improve the performance of a large-scale bending machine

Yes, software and control upgrades improve precision, efficiency, and energy use. Upgrading technology allows the machine to handle complex bending tasks more effectively while extending its lifespan.

Table of Contents

- Importance of Maintaining a Large-Scale Bending Machine

- Daily Maintenance of Large-Scale Bending Machine

- Operational Guidelines for Large-Scale Bending Machine

- Scheduled Maintenance of Large-Scale Bending Machine

- Safety Practices in Operating Large-Scale Bending Machine

- Enhancing Efficiency of Large-Scale Bending Machine

- Long-Term Investment in Large-Scale Bending Machine

- FAQ