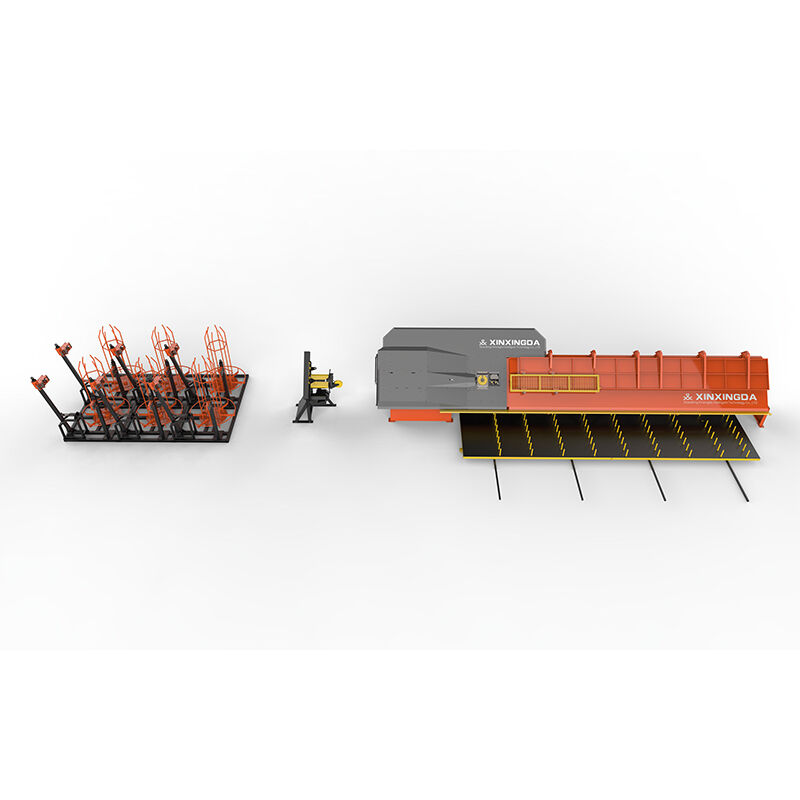

Modern manufacturing demands precision, efficiency, and reliability in every production process. The steel fabrication industry has witnessed remarkable transformation through advanced automation technologies, with CNC steel bar shearing production line systems leading this revolutionary change. These sophisticated manufacturing solutions combine computer numerical control technology with high-performance cutting mechanisms to deliver unparalleled accuracy and productivity in steel bar processing operations.

Industrial manufacturers worldwide increasingly recognize the transformative impact of automated steel processing equipment on their operational capabilities. The integration of computer-controlled systems with traditional metalworking processes has opened new possibilities for achieving consistent quality standards while maintaining competitive production costs. This technological advancement represents a significant leap forward from conventional manual cutting methods that often struggled with precision requirements and production volume limitations.

Enhanced Precision and Accuracy Benefits

Computer-Controlled Cutting Precision

The implementation of computer numerical control technology in steel bar shearing operations delivers exceptional cutting precision that surpasses traditional manual methods by significant margins. Advanced servo motors and precision linear guides work in perfect synchronization to maintain cutting tolerances within microsecond accuracy levels. This remarkable precision ensures that each steel bar segment meets exact dimensional specifications without the variations commonly associated with human-operated equipment.

Sophisticated feedback systems continuously monitor cutting blade position and automatically compensate for any detected deviations during the shearing process. The integration of high-resolution encoders and advanced positioning algorithms enables the system to maintain consistent cutting angles and depths across thousands of operational cycles. This level of accuracy proves particularly valuable in applications requiring tight dimensional tolerances for subsequent assembly or welding operations.

Consistent Quality Standards

Quality consistency represents one of the most significant advantages offered by automated steel bar processing systems. Unlike manual operations that depend heavily on operator skill levels and physical condition variations, computerized systems maintain identical performance standards throughout extended production runs. The elimination of human variability factors ensures that the first piece produced matches the quality characteristics of the thousandth piece with remarkable consistency.

Advanced quality control mechanisms integrated within the system continuously monitor cutting parameters and automatically adjust operational settings to maintain optimal performance levels. Real-time data collection capabilities enable immediate identification of potential quality issues before they impact production output. This proactive approach to quality management significantly reduces material waste and eliminates the costs associated with rework or rejected components.

Production Efficiency Improvements

Increased Processing Speed

Modern CNC steel bar shearing production line systems achieve processing speeds that dramatically exceed conventional cutting methods while maintaining superior quality standards. High-speed hydraulic systems combined with optimized cutting blade designs enable rapid cycle times that can process multiple steel bars simultaneously. The elimination of manual handling and setup procedures between cutting operations contributes significantly to overall throughput improvements.

Automated material feeding systems ensure continuous operation without interruptions for manual loading or positioning activities. The integration of sophisticated scheduling algorithms optimizes cutting sequences to minimize material waste and reduce setup times between different bar sizes or specifications. These efficiency improvements translate directly into increased daily production capacity and improved delivery schedule performance.

Reduced Labor Requirements

The automation capabilities inherent in advanced steel processing systems significantly reduce the number of operators required for production activities. A single skilled technician can effectively supervise multiple automated production lines simultaneously, representing a substantial improvement over traditional manufacturing approaches that required dedicated operators for each cutting station. This reduction in labor requirements delivers immediate cost savings while improving overall operational safety.

Simplified operation interfaces and automated safety systems enable rapid training of new operators without extensive specialized knowledge requirements. The reduction in physical labor demands also decreases employee fatigue and injury risks associated with manual steel handling operations. These improvements in working conditions contribute to better employee retention rates and reduced training costs for replacement personnel.

Cost-Effectiveness and Return on Investment

Material Waste Reduction

Precision cutting capabilities delivered by automated systems result in significant material waste reduction compared to traditional cutting methods. Advanced optimization software calculates optimal cutting patterns that maximize material utilization while minimizing scrap generation. The system automatically adjusts cutting sequences to accommodate various bar lengths and specifications within the same production run, further reducing waste percentages.

Real-time measurement systems verify material dimensions before cutting operations commence, ensuring that only conforming materials proceed through the production process. This early detection capability prevents the processing of defective raw materials that would otherwise result in unusable finished products. The cumulative effect of these waste reduction measures delivers substantial cost savings over extended operational periods.

Long-Term Operational Savings

Investment in automated steel processing equipment generates substantial long-term operational savings through multiple cost reduction mechanisms. Reduced labor requirements, decreased material waste, and improved production efficiency combine to deliver attractive return on investment calculations. The elimination of overtime costs associated with meeting production deadlines provides additional financial benefits that improve overall profitability.

Predictive maintenance capabilities integrated within modern systems reduce unexpected equipment downtime and extend component service life. Advanced diagnostic systems continuously monitor critical components and provide early warning notifications before failures occur. This proactive maintenance approach minimizes costly emergency repairs and reduces the inventory requirements for spare parts storage.

Advanced Safety Features

Automated Safety Systems

Contemporary CNC steel bar shearing production line equipment incorporates comprehensive safety systems that exceed traditional industrial safety standards. Multiple safety sensors and emergency stop mechanisms provide immediate protection for operators and equipment during normal operations and emergency situations. Light curtains and pressure-sensitive safety mats create invisible barriers that prevent accidental contact with moving machinery components.

Integrated safety logic controllers continuously monitor all system parameters and automatically initiate protective sequences when potential hazards are detected. The elimination of manual handling requirements for heavy steel bars reduces the risk of musculoskeletal injuries commonly associated with traditional steel processing operations. These enhanced safety features contribute to improved workplace safety records and reduced workers' compensation costs.

Environmental Protection Benefits

Modern automated systems incorporate environmental protection features that minimize the ecological impact of steel processing operations. Enclosed cutting chambers contain metal particles and cutting fluids, preventing environmental contamination and improving workplace air quality. Advanced filtration systems capture and recycle cutting oils, reducing waste disposal requirements and associated environmental costs.

Noise reduction technologies integrated within system designs significantly decrease operational noise levels compared to conventional cutting equipment. This improvement in acoustic performance enables compliance with stringent environmental regulations while creating more comfortable working conditions for facility personnel. The reduction in environmental impact supports corporate sustainability initiatives and community relations programs.

Integration and Scalability Advantages

Manufacturing System Integration

Advanced steel processing systems offer seamless integration capabilities with existing manufacturing execution systems and enterprise resource planning platforms. Standardized communication protocols enable real-time data exchange between production equipment and management systems, providing comprehensive visibility into operational performance metrics. This integration capability supports advanced production planning and scheduling optimization initiatives.

The ability to interface with upstream and downstream production equipment creates opportunities for fully automated material flow throughout the manufacturing facility. Automated material handling systems can deliver raw materials to the cutting station and transport finished products to subsequent processing operations without manual intervention. This level of integration maximizes overall facility efficiency and reduces labor requirements across multiple production processes.

Future Expansion Capabilities

Modular system designs enable straightforward capacity expansion as production requirements grow over time. Additional cutting stations or enhanced processing capabilities can be integrated into existing installations without major facility modifications or extended downtime periods. This scalability advantage provides manufacturers with the flexibility to adapt their production capabilities to changing market demands and business growth opportunities.

Software upgrade capabilities ensure that systems remain current with evolving technology standards and industry requirements. Regular updates deliver enhanced functionality and improved performance characteristics without requiring hardware replacement investments. This upgrade path protects long-term equipment investments while maintaining competitive operational capabilities.

FAQ

What maintenance requirements are associated with CNC steel bar shearing systems

Modern CNC steel bar shearing production line systems require routine maintenance activities including hydraulic fluid changes, cutting blade inspections, and lubrication of moving components. Most systems incorporate automated maintenance reminder systems that notify operators when specific maintenance tasks are due. The predictive maintenance capabilities built into these systems help prevent unexpected failures and extend component service life significantly.

How do these systems handle different steel bar sizes and materials

Advanced systems feature adjustable tooling and programmable parameters that accommodate wide ranges of steel bar diameters and material specifications. Quick-change tooling systems enable rapid transitions between different bar sizes with minimal setup time requirements. The control software stores cutting parameters for various materials and automatically adjusts operational settings based on the selected material specifications.

What training is required for operators of automated steel processing equipment

Operator training typically requires several days of instruction covering system operation, safety procedures, and basic troubleshooting techniques. Most manufacturers provide comprehensive training programs that include hands-on experience with the equipment and detailed documentation for reference purposes. The intuitive user interfaces incorporated in modern systems reduce the learning curve and enable operators to achieve proficiency quickly.

How do these systems contribute to overall facility productivity improvements

Automated steel processing systems contribute to facility-wide productivity improvements through reduced material handling requirements, improved production scheduling flexibility, and enhanced quality consistency. The integration capabilities enable optimized material flow throughout the facility and provide real-time production data for management decision-making. These improvements typically result in measurable increases in overall equipment effectiveness and facility throughput capacity.

Table of Contents

- Enhanced Precision and Accuracy Benefits

- Production Efficiency Improvements

- Cost-Effectiveness and Return on Investment

- Advanced Safety Features

- Integration and Scalability Advantages

-

FAQ

- What maintenance requirements are associated with CNC steel bar shearing systems

- How do these systems handle different steel bar sizes and materials

- What training is required for operators of automated steel processing equipment

- How do these systems contribute to overall facility productivity improvements