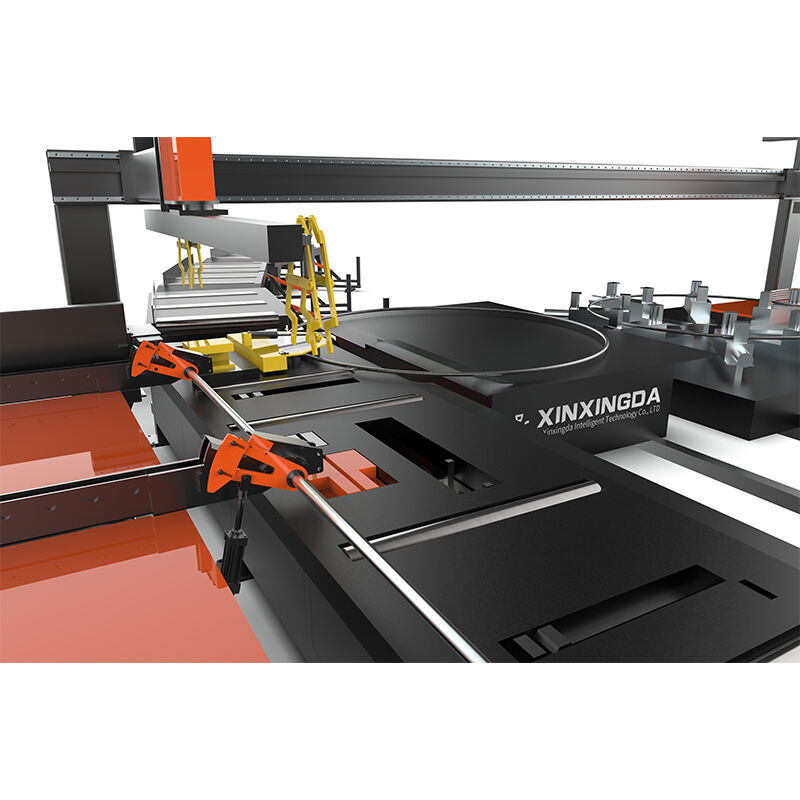

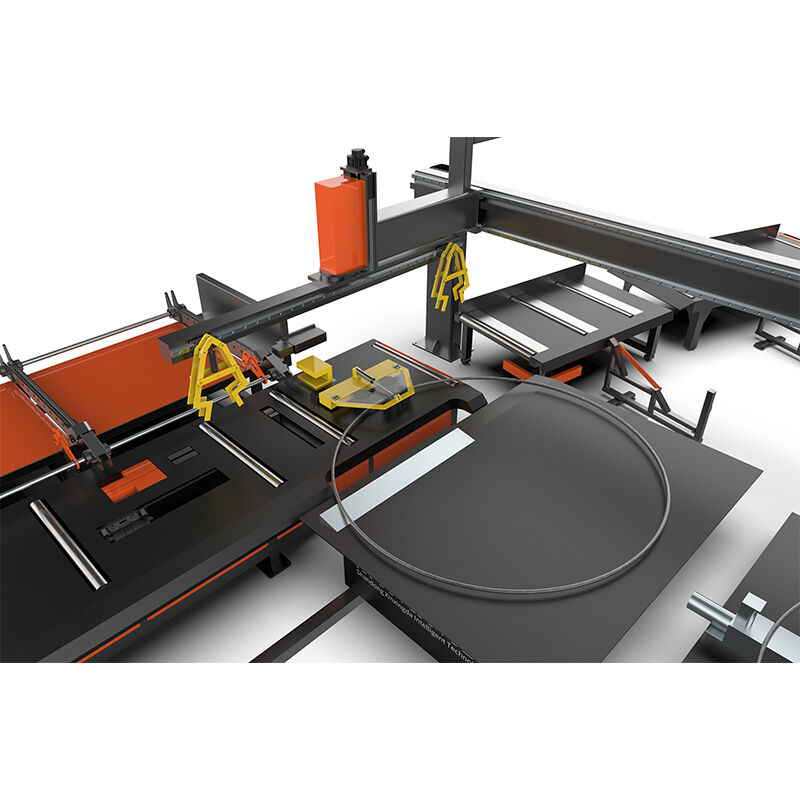

Modern manufacturing industries increasingly demand precision in metal fabrication, particularly when creating curved and circular components. The circle and arc bending machine has emerged as an essential tool for transforming straight metal bars, rods, and tubes into perfectly curved shapes required across numerous industrial applications. This sophisticated machinery combines advanced engineering principles with computer-controlled precision to deliver consistent results that meet strict quality standards.

The versatility of these machines extends far beyond simple bending operations, encompassing complex geometries and multi-dimensional curves that would be impossible to achieve through manual processes. Industries ranging from construction and automotive to aerospace and marine engineering rely heavily on the precision and efficiency that circle and arc bending technology provides. Understanding which applications specifically benefit from this technology helps manufacturers make informed decisions about equipment investments and production capabilities.

Construction and Infrastructure Applications

Reinforcement Steel Processing

The construction industry represents one of the largest consumers of circle and arc bending machine technology, particularly for processing reinforcement steel bars. Modern building designs frequently incorporate curved architectural elements, decorative facades, and structural components that require precisely bent reinforcement materials. These machines can handle various rebar diameters while maintaining the exact radius specifications required by structural engineers.

Stadium construction, bridge building, and high-rise developments often feature complex curved concrete sections that demand custom-bent reinforcement patterns. The circle and arc bending machine ensures that each reinforcement bar meets exact specifications, contributing to structural integrity and safety compliance. Additionally, these machines significantly reduce material waste by eliminating the need for multiple joints and connections in curved sections.

Architectural Metalwork

Contemporary architecture increasingly emphasizes flowing, organic shapes that create visually striking building exteriors and interiors. Circle and arc bending machines enable fabricators to create curved handrails, decorative screens, window frames, and structural supports that complement modern architectural designs. The precision achievable through automated bending ensures consistent curvature across large installations, maintaining aesthetic continuity throughout entire projects.

Custom metalwork for luxury residential and commercial projects often requires unique curved elements that cannot be produced using standard fabrication techniques. These machines provide the flexibility to create one-off pieces while maintaining the same high-quality finish and dimensional accuracy as mass-produced components. The ability to work with various metals including stainless steel, aluminum, and specialty alloys makes these machines invaluable for high-end architectural applications.

Automotive and Transportation Manufacturing

Vehicle Frame Components

The automotive industry relies extensively on circle and arc bending technology for manufacturing vehicle frames, roll cages, and chassis components. Modern vehicle designs prioritize both safety and aerodynamics, requiring complex curved structures that distribute impact forces effectively while minimizing air resistance. Circle and arc bending machines produce these critical components with the precision necessary to meet stringent safety regulations and performance standards.

Electric vehicle manufacturing has introduced new challenges in frame design, as battery placement and weight distribution requirements often necessitate unique curved configurations. These machines adapt to evolving automotive designs by providing the flexibility to create custom geometries while maintaining production efficiency. The repeatability of automated bending processes ensures that each vehicle meets identical specifications, critical for mass production environments.

Exhaust System Manufacturing

Automotive exhaust systems require complex routing through vehicle undercarriages, necessitating precise bends and curves to avoid interference with other components. Circle and arc bending machines produce exhaust tubes and pipes with smooth internal surfaces that optimize gas flow while fitting within tight spatial constraints. The ability to create compound curves in a single operation reduces the need for welded joints, improving system durability and performance.

Performance exhaust systems for racing and high-performance vehicles demand even greater precision in bend angles and radii to maximize exhaust flow efficiency. These specialized applications benefit from the advanced programming capabilities of modern circle and arc bending machines, which can store multiple bend sequences and reproduce them with micron-level accuracy. The consistency achievable through automated processes ensures that each exhaust system delivers identical performance characteristics.

Aerospace and Aviation Industries

Aircraft Frame Manufacturing

Aerospace applications represent perhaps the most demanding use cases for circle and arc bending technology, where precision tolerances measured in thousandths of an inch are standard requirements. Aircraft frame components, including fuselage rings, wing ribs, and structural supports, must maintain exact dimensions under extreme stress and temperature variations. Circle and arc bending machines equipped with advanced control systems can achieve the precision necessary for these critical applications.

The aerospace industry's emphasis on weight reduction drives demand for complex curved components that eliminate unnecessary material while maintaining structural integrity. These machines enable manufacturers to create lightweight, high-strength components that meet strict aviation safety standards. The traceability and documentation capabilities built into modern bending systems also support the extensive quality control requirements typical of aerospace manufacturing.

Satellite and Space Vehicle Components

Space exploration and satellite technology require specialized curved components that can withstand the extreme conditions of space while maintaining precise functionality. Circle and arc bending machines produce antenna supports, solar panel frames, and structural elements for satellites and space vehicles. The ability to work with exotic materials such as titanium alloys and composite-reinforced metals makes these machines essential for space industry applications.

The unique environmental challenges of space applications demand components with perfect geometric accuracy and superior material properties. Circle and arc bending technology enables manufacturers to create these specialized components while maintaining the cleanliness and precision standards required for space-grade hardware. The repeatability of automated processes ensures that replacement parts can be manufactured to identical specifications when needed for mission-critical applications.

Marine and Offshore Applications

Ship Hull Construction

Modern shipbuilding relies heavily on curved structural elements that provide both strength and hydrodynamic efficiency. Circle and arc bending machines are essential for creating the complex curves required in ship hull frames, deck supports, and bulkhead structures. The marine environment's corrosive nature demands precision in every joint and connection, making the accuracy of these machines crucial for long-term vessel integrity.

Large-scale marine vessels require extensive curved framework that would be prohibitively expensive to manufacture using traditional methods. These machines enable shipyards to produce complex hull sections efficiently while maintaining the dimensional accuracy necessary for proper assembly. The ability to handle heavy-section materials typical in marine construction makes circle and arc bending technology indispensable for modern shipbuilding operations.

Offshore Platform Manufacturing

Offshore oil and gas platforms operate in some of the world's harshest environments, requiring structural components that can withstand extreme weather, corrosive saltwater, and massive mechanical loads. Circle and arc bending machines produce the curved bracing, piping supports, and structural elements that form the backbone of these critical installations. The precision achievable through automated bending ensures that each component fits perfectly during offshore assembly operations.

The remote nature of offshore installations makes component reliability absolutely critical, as repairs and replacements are extremely costly and time-consuming. Circle and arc bending technology contributes to this reliability by producing components with consistent material properties and precise dimensions that eliminate potential failure points. The advanced programming capabilities of these machines also enable manufacturers to create spare components that exactly match original specifications when replacement becomes necessary.

Industrial Equipment and Machinery

Heat Exchanger Manufacturing

Industrial heat exchangers require precisely curved tubing to maximize heat transfer efficiency while fitting within compact equipment envelopes. Circle and arc bending machines produce the complex coil configurations necessary for optimal thermal performance in applications ranging from power generation to chemical processing. The smooth internal surfaces achievable through controlled bending processes minimize pressure drops and turbulence that can reduce heat transfer efficiency.

Custom heat exchanger designs for specialized industrial processes often require unique tube configurations that cannot be achieved using standard manufacturing methods. These machines provide the flexibility to create one-off designs while maintaining the precision necessary for effective heat transfer. The ability to work with various tube materials, including stainless steel, copper, and exotic alloys, makes circle and arc bending technology essential for diverse industrial applications.

Pressure Vessel Components

Pressure vessel manufacturing demands components that can withstand extreme internal pressures while maintaining structural integrity over extended service lives. Circle and arc bending machines produce the curved sections, nozzles, and reinforcement rings that are critical components of pressure vessels used in chemical processing, power generation, and other industrial applications. The precision achievable through automated bending helps eliminate stress concentrations that could lead to premature failure.

The regulatory requirements governing pressure vessel construction demand extensive documentation and quality control throughout the manufacturing process. Modern circle and arc bending machines provide the traceability and repeatability necessary to meet these stringent requirements while maintaining production efficiency. The ability to create complex geometries in a single operation reduces the number of welds and joints required, improving overall vessel reliability and service life.

FAQ

What materials can circle and arc bending machines process effectively

Circle and arc bending machines can process a wide range of materials including carbon steel, stainless steel, aluminum, copper, titanium, and various specialty alloys. The specific material capabilities depend on the machine's power rating, tooling configuration, and control system sophistication. Most modern machines can handle material thicknesses from thin-wall tubing to heavy structural sections, with some specialized units capable of bending materials up to several inches in diameter.

How do these machines maintain accuracy across different bend radii

Advanced circle and arc bending machines utilize servo-controlled positioning systems and sophisticated software algorithms to maintain accuracy across varying bend radii. The machines compensate for material springback, work hardening effects, and thermal expansion through real-time monitoring and adjustment systems. High-precision encoders and feedback sensors continuously monitor bend angles and radii, making automatic corrections to ensure final dimensions meet specified tolerances.

What are the typical production rates for circle and arc bending operations

Production rates vary significantly based on material type, bend complexity, and required precision levels. Simple circular bends in standard materials can often be completed in under a minute, while complex multi-radius curves may require several minutes per piece. Automated loading and unloading systems can significantly improve overall production efficiency, with some installations achieving cycle times of less than 30 seconds for repetitive operations.

How do operators program complex bend sequences into these machines

Modern circle and arc bending machines feature user-friendly programming interfaces that allow operators to input bend sequences through touchscreen controls or computer-aided design integration. Many systems support parametric programming, where operators can specify geometric requirements and the machine automatically calculates the necessary bend sequences. Advanced machines may also include simulation capabilities that allow operators to visualize the bending process before actual production begins.