Modern construction projects demand precision, efficiency, and reliability at every stage of development. Today's builders face increasing pressure to deliver high-quality structures within tight deadlines while maintaining cost-effectiveness and safety standards. Construction processing equipment has emerged as a game-changing solution that addresses these challenges by automating complex tasks, reducing manual labor requirements, and ensuring consistent results across various construction applications.

The construction industry has witnessed remarkable technological advancement in recent decades, with specialized machinery becoming increasingly sophisticated and versatile. These innovations have transformed traditional building methods, enabling contractors to tackle more complex projects while maintaining competitive advantages in an evolving marketplace. Understanding the benefits of modern processing equipment helps builders make informed decisions about their investment strategies and operational improvements.

Enhanced Productivity and Time Management

Accelerated Project Completion

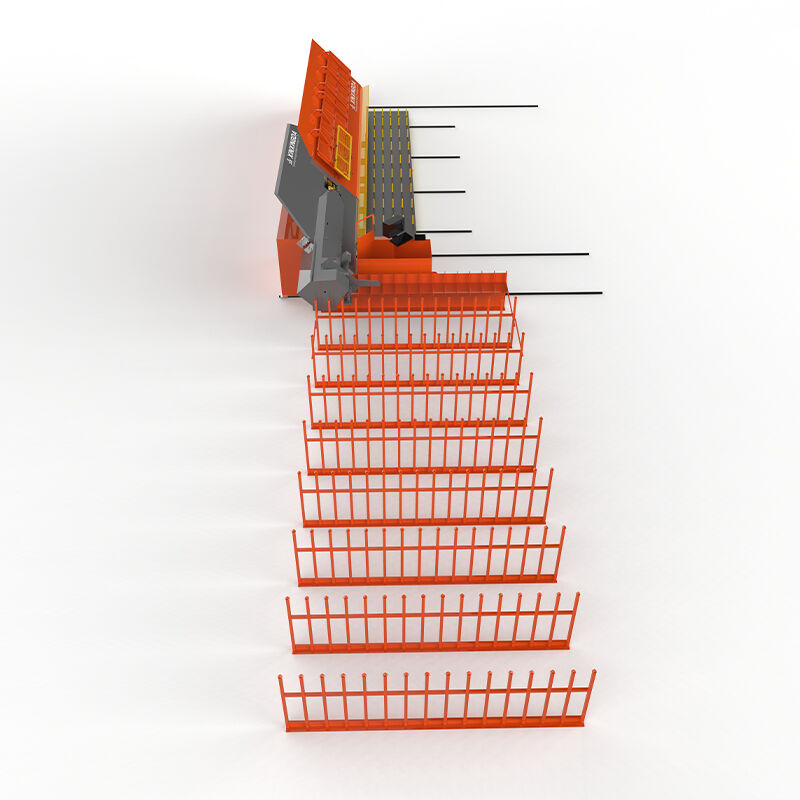

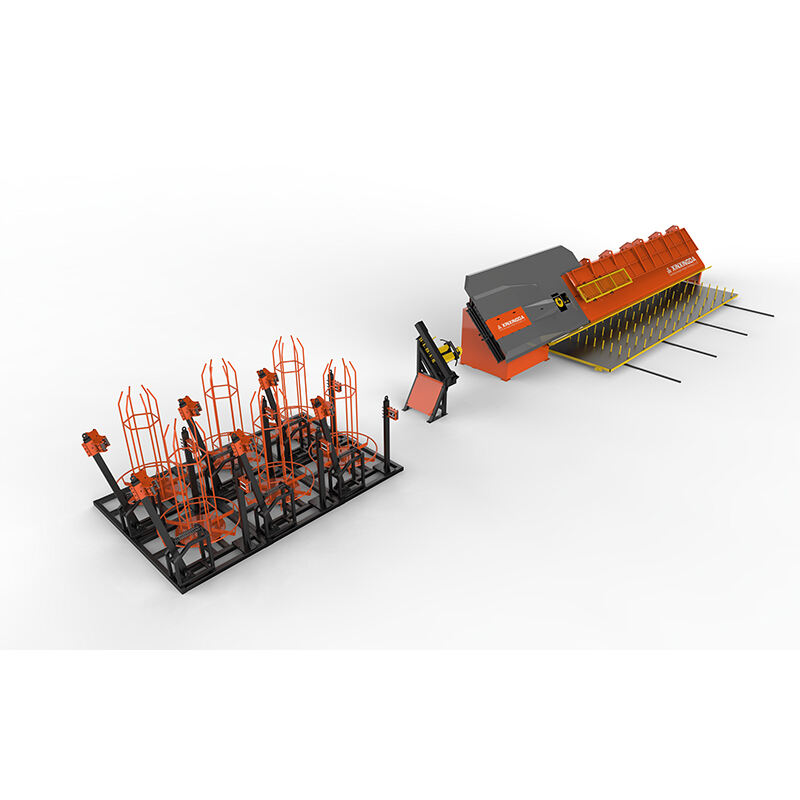

Advanced construction processing equipment significantly reduces the time required for various building operations compared to traditional manual methods. Automated steel bar bending machines, concrete mixers, and cutting tools can complete tasks in minutes that would otherwise take hours of manual labor. This acceleration allows construction teams to meet aggressive project deadlines while maintaining quality standards throughout the building process.

The speed advantage becomes particularly evident in large-scale commercial and residential developments where repetitive tasks are common. Modern equipment can maintain consistent output rates regardless of weather conditions or worker fatigue, ensuring steady progress toward project milestones. This reliability helps contractors avoid costly delays and maintain client satisfaction levels.

Streamlined Workflow Integration

Contemporary construction processing equipment integrates seamlessly with existing workflow management systems, creating synchronized operations across multiple work sites. Digital controls and programmable features allow operators to coordinate equipment functions with project schedules, material deliveries, and quality control checkpoints. This integration minimizes downtime between operations and maximizes resource utilization efficiency.

Smart equipment systems can communicate with project management software to provide real-time progress updates and performance metrics. Construction managers gain valuable insights into operational efficiency, enabling them to make data-driven decisions about resource allocation and process optimization. This connectivity transforms traditional construction sites into intelligent, responsive work environments.

Superior Quality Control and Precision

Consistent Manufacturing Standards

Precision-engineered construction processing equipment delivers repeatable results that meet or exceed industry standards for accuracy and dimensional tolerance. Computer-controlled systems eliminate human error variables while ensuring each component meets exact specifications throughout the manufacturing process. This consistency reduces material waste and minimizes the need for costly rework or repairs.

Quality control systems built into modern equipment provide continuous monitoring of output parameters, automatically adjusting operations to maintain optimal performance levels. These systems detect deviations from established standards and alert operators to potential issues before they impact final product quality. Such proactive quality management protects builders from liability issues and enhances their reputation for excellence.

Advanced Material Optimization

Sophisticated processing equipment maximizes material utilization through intelligent cutting algorithms and waste reduction protocols. Advanced nesting software calculates optimal material layouts to minimize scrap generation while maintaining structural integrity requirements. This optimization reduces material costs and supports sustainable construction practices by minimizing environmental impact.

Modern equipment also accommodates various material types and specifications without requiring extensive reconfiguration or specialized tooling. This versatility allows builders to adapt quickly to changing project requirements or material availability constraints while maintaining consistent quality standards. The flexibility reduces inventory requirements and improves project cost predictability.

Cost Efficiency and Return on Investment

Reduced Labor Dependencies

Automated construction processing equipment significantly reduces the number of skilled workers required for complex manufacturing tasks while improving overall job site safety. This reduction addresses the ongoing skilled labor shortage affecting the construction industry while maintaining or improving productivity levels. Equipment operators can manage multiple processes simultaneously, multiplying individual worker effectiveness.

The decreased reliance on manual labor also reduces exposure to workplace injuries and associated workers' compensation costs. Automated systems handle hazardous operations safely, protecting workers from repetitive strain injuries and exposure to dangerous materials. This safety improvement creates a more attractive work environment and reduces employee turnover rates.

Long-term Operational Savings

While initial equipment investment costs may seem substantial, the long-term operational savings typically justify the expense within the first few years of operation. Reduced material waste, faster completion times, and lower labor costs combine to create significant cost advantages over traditional construction methods. These savings compound over time, improving overall project profitability.

Modern equipment also features improved durability and reliability compared to older generation machinery, reducing maintenance costs and extending operational lifespans. Predictive maintenance systems monitor component wear and performance degradation, enabling proactive maintenance scheduling that prevents costly breakdowns and production interruptions. This reliability ensures consistent equipment availability when needed most.

Safety Enhancement and Risk Mitigation

Automated Safety Systems

Contemporary construction processing equipment incorporates comprehensive safety systems designed to protect operators and nearby workers from potential hazards. Emergency stop mechanisms, safety interlocks, and protective barriers prevent accidents while maintaining operational efficiency. These systems comply with strict industry safety standards and often exceed minimum regulatory requirements.

Advanced sensor technologies monitor work zones continuously, detecting unauthorized personnel entry and automatically stopping operations when safety protocols are violated. Visual and audible warning systems alert workers to potential dangers, while safety training modules built into equipment interfaces ensure proper operating procedures are followed consistently.

Environmental Compliance Benefits

Modern construction processing equipment incorporates environmental protection features that help builders comply with increasingly stringent environmental regulations. Dust collection systems, noise reduction technologies, and emission control mechanisms minimize environmental impact while maintaining operational effectiveness. These features protect both workers and surrounding communities from construction-related pollution.

Equipment manufacturers continue developing more environmentally friendly technologies, including electric-powered alternatives to diesel-driven machinery and systems designed for maximum energy efficiency. These innovations help construction companies meet sustainability goals while reducing operational costs and regulatory compliance burdens.

Technology Integration and Future Readiness

Digital Connectivity Features

State-of-the-art construction processing equipment features advanced connectivity options that enable remote monitoring, diagnostics, and control capabilities. These digital interfaces allow project managers to oversee multiple equipment installations from centralized locations while maintaining real-time visibility into operational performance and maintenance requirements.

Cloud-based data collection systems aggregate performance metrics and operational data for analysis and optimization purposes. This information helps contractors identify efficiency improvement opportunities and make informed decisions about equipment upgrades or process modifications. The data also supports predictive analytics applications that can forecast equipment maintenance needs and optimize resource allocation.

Scalability and Adaptability

Modern equipment designs emphasize modularity and upgradability, allowing construction companies to expand capabilities as business needs evolve. Software updates can add new functionality without requiring hardware replacement, while modular components enable customization for specific project requirements. This flexibility protects equipment investments while ensuring continued competitiveness in changing market conditions.

The adaptability of contemporary construction processing equipment also supports diversification into new market segments or construction techniques. Equipment that can handle multiple material types or processing methods provides builders with flexibility to pursue various project opportunities without requiring additional capital investments in specialized machinery.

FAQ

What factors should builders consider when selecting construction processing equipment

Builders should evaluate project requirements, volume expectations, available space, power infrastructure, and operator skill levels when selecting equipment. Consider total cost of ownership including maintenance, training, and potential productivity gains versus initial purchase price. Compatibility with existing systems and future expansion plans should also influence equipment selection decisions.

How does construction processing equipment impact project scheduling and deadlines

Advanced equipment typically accelerates project completion by automating time-consuming tasks and eliminating manual processing bottlenecks. Consistent output rates and reduced setup times enable more accurate scheduling predictions and improved deadline adherence. However, proper planning and operator training are essential to realize these scheduling benefits effectively.

What maintenance requirements are associated with modern construction processing equipment

Contemporary equipment features predictive maintenance systems that monitor component wear and performance indicators to schedule maintenance proactively. Regular preventive maintenance includes lubrication, calibration, and inspection procedures outlined in manufacturer guidelines. Many systems provide maintenance alerts and diagnostic information to simplify upkeep requirements and prevent unexpected breakdowns.

Can smaller construction companies benefit from investing in processing equipment

Smaller companies can benefit through improved efficiency, quality, and competitive positioning, though investment decisions should consider project volume and equipment utilization rates. Leasing or rental options may provide access to advanced equipment without large capital commitments. Partnerships or equipment sharing arrangements with other contractors can also make advanced technology more accessible for smaller operations.

Table of Contents

- Enhanced Productivity and Time Management

- Superior Quality Control and Precision

- Cost Efficiency and Return on Investment

- Safety Enhancement and Risk Mitigation

- Technology Integration and Future Readiness

-

FAQ

- What factors should builders consider when selecting construction processing equipment

- How does construction processing equipment impact project scheduling and deadlines

- What maintenance requirements are associated with modern construction processing equipment

- Can smaller construction companies benefit from investing in processing equipment