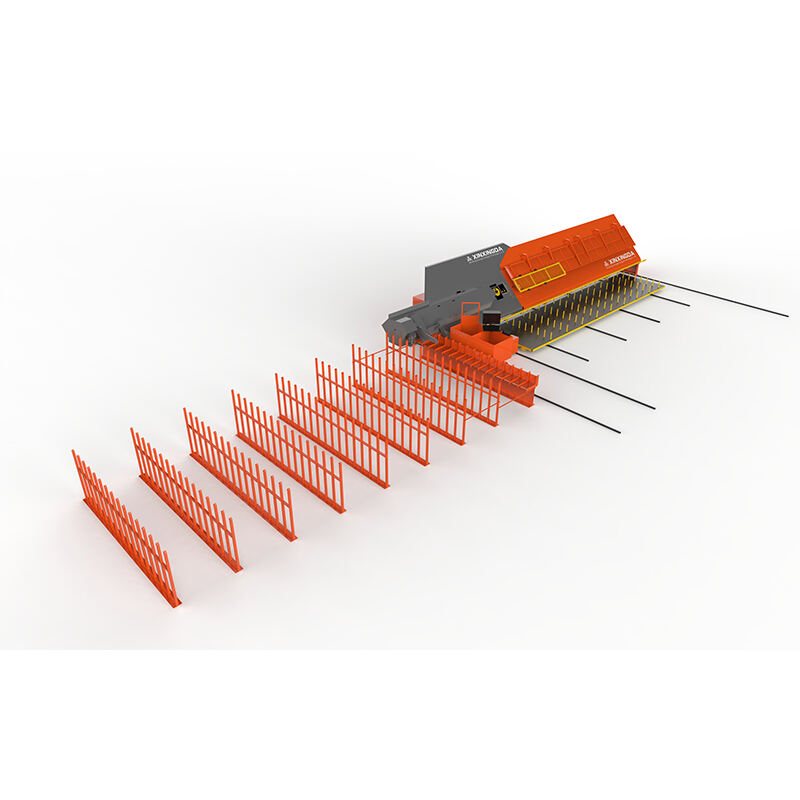

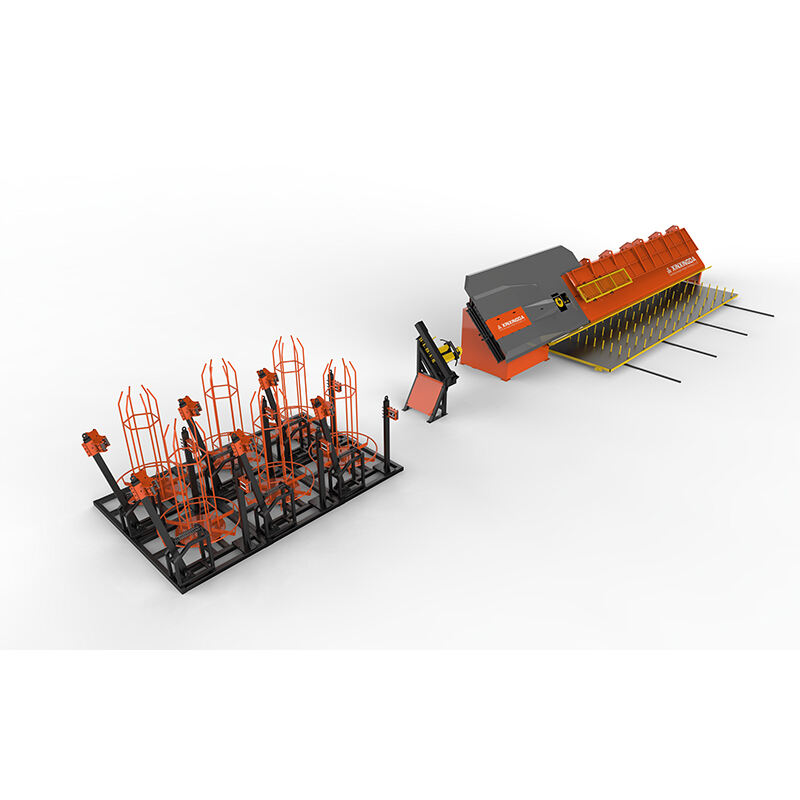

တည်ဆောက်ရေးနှင့် ထုတ်လုပ်မှုလုပ်ငန်းများတွင် သတ္တုပစ္စည်းလုပ်ငန်းဆောင်တာများအတွက် တိကျမှုနှင့် ယုံကြည်စိတ်ချရမှုသည် အလွန်အရေးကြီးပါသည်။ စက်ဝိုင်းနှင့် အကွေးကွင်းကွေးစက် ဗဟိုနှင့် အတွင်းဘက် ကွေးခြင်းစက်များသည် ကွေးညွှတ်ထားသော ဖွဲ့စည်းပုံဒီဇိုင်းများ၊ အလှဆင်ပစ္စည်းများနှင့် အထူးပြု အဆောက်အဦဒီဇိုင်းများကို ဖန်တီးရာတွင် အရေးပါဆုံးကိရိယာများထဲမှ တစ်ခုဖြစ်သည်။ ဤကဲ့သို့သော ရှုပ်ထွေးသည့်စက်များသည် ၎င်းတို့၏ ကွေးခြင်းလုပ်ငန်းများတွင် အထူးသဖြင့် တိကျမှုကို ထိန်းသိမ်းထားရင်း ခက်ခဲသော အခြေအနေများအောက်တွင် တစ်သမတ်တည်း စွမ်းဆောင်နိုင်ရမည်။ စက်၏ ယုံကြည်စိတ်ချရမှုကို မြှင့်တင်ပေးသည့် အဓိက အင်္ဂါရပ်များကို နားလည်ခြင်းဖြင့် ဤအရေးကြီးသော ပစ္စည်းကိရိယာများကို ရင်းနှီးမြှုပ်နှံရာတွင် လုပ်ငန်းများအနေဖြင့် သင့်တော်သော ဆုံးဖြတ်ချက်များ ချမှတ်နိုင်မည်ဖြစ်သည်။

ကွေးခြင်းစက်၏ ယုံကြည်စိတ်ချရမှုသည် ထုတ်လုပ်မှု ထိရောက်မှု၊ ထုတ်ကုန်အရည်အသွေးနှင့် စုစုပေါင်း လည်ပတ်မှုစရိတ်တို့ကို တိုက်ရိုက်သက်ရောက်မှုရှိသည်။ မော်ဒယ်များနှင့် ထုတ်လုပ်သူများကို အကဲဖြတ်ရာတွင် လည်ပတ်သူများသည် အဆင့်မြင့်ပစ္စည်းကိရိယာများကို စံသတ်မှတ်ထားသော အစားထိုးနည်းများမှ ခွဲခြားပေးသည့် နည်းပညာဆိုင်ရာ အသေးစိတ်အချက်အလက်များ၊ တည်ဆောက်မှုအရည်အသွေး အချက်များနှင့် စွမ်းဆောင်ရည် ဂုဏ်သတ္တိများကို ထည့်သွင်းစဉ်းစားရန် လိုအပ်သည်။ ခေတ်မီ ဝိုင်းနှင့် ကမ္ဘာ့ကွေးခြင်းစက်များသည် သက်တမ်းရှည်ခိုင်ခံ့မှု၊ တိကျမှုနှင့် လည်ပတ်မှုကာလကို မြှင့်တင်ပေးသည့် နည်းပညာများနှင့် အင်ဂျင်နီယာဖြေရှင်းချက်များကို ပေါင်းစပ်ထားသည်။

ဖွဲ့စည်းပုံအခြေခံမူနှင့် ကွန်ရိုးဒီဇိုင်း

ခိုင်ခံ့သော ကွန်ရိုးတည်ဆောက်မှု

ယုံကြည်စိတ်ချရသော စက်ဝိုင်းနှင့် ကွေးညွှန်းစက်တစ်ခု၏ အခြေခံအုတ်မြစ်သည် ၎င်း၏ဖွဲ့စည်းပုံအုတ်မြစ်မှ စတင်ပါသည်။ အဆင့်မြင့်စက်များတွင် ကွေးညွှန်းလုပ်ငန်းဆောင်တာများအတွင်း ဖြစ်ပေါ်လာသော အင်အားကြီးမားမှုများကို ခံနိုင်ရည်ရှိသည့် အဆင့်မြင့်သံမဏိကွန်ရိုးများကို အသုံးပြုထားပါသည်။ ဤကွန်ရိုးများတွင် အားဖြည့်ဘားများ၊ နေရာကျဉ်းကျဉ်းတွင် ဖြတ်ပိုင်းများနှင့် တိကျသော စက်ဖြင့် ကွားထားသည့် မျက်နှာပြင်များ ပါဝင်လေ့ရှိပြီး နှစ်ပေါင်းများစွာ ဆက်တိုက်အသုံးပြုမှုအတွင်း အရွယ်အစားတည်ငြိမ်မှုကို ထိန်းသိမ်းပေးပါသည်။ ကွန်ရိုးဒီဇိုင်းသည် ကွေးညွှန်းအားများကို ညီတူညီမျှ ဖြန့်ဖြူးပေးရမည်ဖြစ်ပြီး တိကျမှုကို ထိခိုက်စေနိုင်သည့် ဗဟိုချက်လွဲမှုနှင့် တုန်ခါမှုများကို အနည်းဆုံးဖြစ်အောင် လျှော့ချပေးရမည်ဖြစ်ပါသည်။

ဤဖရိမ်များအတွက် ထုတ်လုပ်မှုလုပ်ငန်းစဉ်များတွင် ကွေးခြင်း သို့မဟုတ် အရွယ်အစားပြောင်းလဲမှုများကို ဖြစ်ပေါ်စေနိုင်သည့် အတွင်းပိုင်းဖိအားများကို ဖယ်ရှားရန် စိတ်ဖိစီးမှု လျော့နည်းစေသည့် ကုသမှုများနှင့် တိကျသော စက်ပြုလုပ်မှုများ ပါဝင်လေ့ရှိသည်။ အကောင်းဆုံးစက်များသည် လုပ်ငန်းဆောင်တာများအတွင်း ဖိအားများကို စုပ်ယူပေးပြီး အလုပ်အလိုက်ပစ္စည်းပေါ်သို့ တုန်ခါမှုများ မဖြစ်စေရန် လုံလောက်သော အများအားဖြင့် သံလိုက်သံမဏိ (cast iron) သို့မဟုတ် အဆက်ချုပ်ထားသော သံမဏိဖြင့် တည်ဆောက်ထားသည်။ ဤမာကျောသော အုတ်မြစ်သည် ပစ္စည်း၏ ထူးခြားမှု သို့မဟုတ် ကွေးညွှန်းမှု လိုအပ်ချက်များနှင့် မဆိုင်ဘဲ ကွေးညွှန်းမှုလုပ်ငန်းများ တည်ငြိမ်ပြီး ကြိုတင်မြင်နိုင်စေရန် သေချာစေသည်။

တိကျသော တပ်ဆင်မှုစနစ်များ

ယုံကြည်စိတ်ချရသော ကွေးခွင်းစက်များတွင် စက်၏ လည်ပတ်မှုဘဝတစ်လျှောက် ရွေ့လျားနေသော အစိတ်အပိုင်းအားလုံးကြား တိကျသော ဆက်နွယ်မှုကို ထိန်းသိမ်းပေးသည့် ရှုပ်ထွေးသော တည်နေရာချမှတ်မှုစနစ်များ ပါဝင်ပါသည်။ ဤစနစ်များတွင် တိကျစွာ ကြိတ်မှုန်းထားသော လမ်းညွှန်ဘားများ၊ တစ်ဖြောင့်တည်းသော ဘီယာများနှင့် ပုံမှန် wear patterns များကို အတ္တနှင့်အလိုက် ပြင်ဆင်ပေးနိုင်သော ချိန်ညှိမှုစနစ်များ ပါဝင်ပါသည်။ ကွေးခွင်း ဘီးများ၊ ဖိအားစနစ်များနှင့် အလုပ်အပိုင်းလမ်းညွှန်များသည် သတ်မှတ်ထားသော တိကျမှုအတွင်း သတ်မှတ်ထားသော နေရာများတွင် ဆက်လက်ရှိနေစေရန် တည်နေရာချမှတ်မှုစနစ်က သေချာစေရမည်ဖြစ်သည်။

တိုးတက်ထားသော စက်များတွင် တိကျမှုပျက်ပြားမှုမဖြစ်မီ စက်၏ တည်နေရာချမှတ်မှု စနစ်များကို ကိုယ်ပိုင်စောင့်ကြည့်ပြီး စက်ပြင်ဆင်မှုလိုအပ်ချက်များကို လုပ်သားများအား အသိပေးနိုင်သော စနစ်များ ပါဝင်ပါသည်။ ဤတာဝန်ယူမှုပုံစံဖြင့် တည်နေရာချမှတ်မှု ထိန်းသိမ်းမှုကို ဆောင်ရွက်ခြင်းဖြင့် ဈေးကြီးသော ထုတ်လုပ်မှုအမှားများကို ကာကွယ်နိုင်ပြီး စက်၏ အသုံးပြုနိုင်သော သက်တမ်းကို ရှည်လျားစေပါသည်။ ဒစ်ဂျစ်တယ် တိုင်းတာမှုစနစ်များကို ပေါင်းစပ်ခြင်းဖြင့် လည်ပတ်နေစဉ်အတွင်း အရေးကြီးသော တည်နေရာချမှတ်မှုများကို အချိန်နှင့်တစ်ပြေးညီ စောင့်ကြည့်နိုင်ပါသည်။

ဟိုက်ဒရောလစ်နှင့် မောင်းနှင်မှုစနစ်များ

အမြင့်စွမ်းဆောင်ရည်ရှိ ဟိုက်ဒရောလစ် အစိတ်အပိုင်းများ

ဟိုက်ဒရောလစ်စနစ်သည် ခေတ်မီ ပုံသွန်းစက်အများစု၏ နှလုံးသားကို ကိုယ်စားပြုပြီး တသမတ်တည်းရလဒ်များ ရရှိရန် လိုအပ်သော တိကျသည့် အားထိန်းချုပ်မှုကို ပေးဆောင်ပါသည်။ ယုံကြည်စိတ်ချရသော စက်များတွင် အဆက်မပြတ် အသုံးပြုနိုင်ရန်နှင့် တိကျသော ဖိအားထိန်းညှိမှုအတွက် ဒီဇိုင်းထုတ်ထားသည့် အရည်အသွေးမြင့် ဟိုက်ဒရောလစ် ပန့်များ၊ ဗာဗျူများနှင့် စလင်ဒါများကို အသုံးပြုပါသည်။ ဤအစိတ်အပိုင်းများသည် ကွေးခွေမှုလုပ်ငန်းများကို ရှည်လျားစွာ ဆောင်ရွက်နေစဉ်အတွင်း ဖိအားအဆင့်များကို တသမတ်တည်း ထိန်းသိမ်းထားရန် နှင့် ချောမွေ့ပြီး ထိန်းချုပ်နိုင်သော အားကို ပေးဆောင်ရမည်ဖြစ်သည်။

အဆင့်မြင့် ဟိုက်ဒရောလစ်စနစ်များတွင် ကွေးခွေမှုအမြန်နှုန်းနှင့် အားသက်ရောက်မှုကို အဆုံးမဲ့ ချိန်ညှိနိုင်သည့် အချိုးကျထိန်းချုပ်မှုဗာဗျူများ ပါဝင်ပါသည်။ ဤထိန်းချုပ်မှုအဆင့်သည် ပစ္စည်းများနှင့် ဂျီဩမေတြီများအလိုက် ကွေးခွေမှု ပါရာမီတာများကို အကောင်းဆုံးဖြစ်အောင် ပြုလုပ်နိုင်စေပြီး နူးညံ့သော အလုပ်များကို ပျက်စီးမှုမှ ကာကွယ်ပေးပါသည်။ ဟိုက်ဒရောလစ်စနစ်တွင် အစိတ်အပိုင်းများကို ညစ်ညမ်းမှုနှင့် အပူလွန်ကဲမှုမှ ကာကွယ်ပေးသည့် စုတ်ယူမှုစနစ်၊ အပူချိန်ထိန်းချုပ်မှုနှင့် ဖိအားစောင့်ကြည့်မှုစနစ်များ ပါဝင်သင့်ပါသည်။

တိုးတက်သော မော်တာနှင့် မောင်းနှင်မှုနည်းပညာ

ခေတ်မီ စက်ဝိုင်းနှင့် အကွေးကွင်းကွေးစက် စနစ်များသည် တိကျသော တည်နေရာချမှတ်မှုနှင့် ချောမွေ့သော လည်ပတ်မှုကို ရရှိရန် ရှုပ်ထွေးသော မော်တာနှင့် မောင်းနှင်မှုနည်းပညာများအပေါ် အားကိုးနေပါသည်။ Servo motors နှင့် variable frequency drives များသည် ရိုးရှင်းသော အမြန်နှုန်းတစ်ခုတည်းရှိသည့် စနစ်များနှင့် နှိုင်းယှဉ်ပါက အထူးကောင်းမွန်သော အမြန်နှုန်းထိန်းချုပ်မှု၊ တည်နေရာချမှတ်မှုတိကျမှုနှင့် စွမ်းအင်ထိရောက်မှုတို့ကို ပေးဆောင်ပါသည်။ ဤတိုးတက်သော drive များသည် ပစ္စည်းဂုဏ်သတ္တိများနှင့် ကွေးခွင်းလိုအပ်ချက်များပေါ် အခြေခံ၍ လည်ပတ်မှု ပါရာမီများကို အလိုအလျောက် ညှိနှိုင်းပေးနိုင်ပါသည်။

ပြန်လည်အကြံပြုမှုစနစ်များ ပေါင်းစပ်ခြင်းဖြင့် drive ကွဲပြားမှုများသည် ၎င်းတို့၏ စွမ်းဆောင်ရည်ကို ပုံမှန်စောင့်ကြည့်ပြီး ပြင်ဆင်နိုင်ပါသည်။ ပစ္စည်းဂုဏ်သတ္တိများ၊ ကိရိယာ စွန့်ပစ်မှုနှင့် ပတ်ဝန်းကျင်အခြေအနေများတွင် ကွဲပြားမှုများကို အစားထိုးဖြည့်စွက်ပေးပါသည်။ ဤကဲ့သို့ အလိုအလျောက် ချိန်ညှိနိုင်မှုသည် ထုတ်လုပ်မှု လုပ်ငန်းစဉ်များတွင် တသမတ်တည်းရလဒ်များကို သေချာစေပြီး လုပ်သားများ၏ ဝင်ရောက်စွက်ဖက်မှုကို အနည်းဆုံးဖြစ်စေပါသည်။ စွမ်းအင်ချွေတာနိုင်သော drive စနစ်များသည် လည်ပတ်စရိတ်နှင့် စက်အတွင်း အပူထုတ်လုပ်မှုကိုလည်း လျော့ကျစေပါသည်။

ထိန်းချုပ်မှုစနစ်များနှင့် အလိုအလျောက်လုပ်ဆောင်ခြင်း လုပ်ဆောင်ချက်များ

Programmable Logic Controllers များကို အသုံးပြုနိုင်သည်

ခေတ်မီစက်ပေါင်းစက်များတွင် စက်၏လည်ပတ်မှုအားလုံးကို ရှုပ်ထွေးသောဆော့ဖ်ဝဲစနစ်များဖြင့် စီမံခန့်ခွဲသည့် တိုးတက်သော ပရိုဂရမ်ရေးဆွဲနိုင်သည့် လော့ဂစ်ကွန်ထရိုလာများကို ပေါင်းစပ်ထားပါသည်။ ဤကွန်ထရိုလာများသည် စင်ဆာများမှ အချက်အလက်များကို လက်ခံကာ ရှုပ်ထွေးသော လှုပ်ရှားမှုအစီအစဉ်များကို ညှိနှိုင်းပေးပြီး ပြဿနာများကို အလွယ်တကူ ရှာဖွေဖြေရှင်းနိုင်စေရန် စစ်ဆေးရေးစွမ်းရည်များကို ပေးဆောင်ပါသည်။ ထိုကွန်ထရိုလ်စနစ်သည် စက်သမားများအတွက် ရှုပ်ထွေးသော ပေါင်းခြင်းအစီအစဉ်များကို ပရိုဂရမ်လုပ်နိုင်လောက်အောင် ရိုးရှင်းပြီး ထုတ်လုပ်မှုလိုအပ်ချက်များကို ကျယ်ပြန့်စွာ ကိုက်ညီအောင် လိုက်လျောညီထွေဖြစ်စေရန် လုံလောက်သော ပြောင်းလဲနိုင်မှုကို ပေးပို့ရမည်ဖြစ်သည်။

ယုံကြည်စိတ်ချရသော ထိန်းချုပ်မှုစနစ်များတွင် အကာအကွယ်ဆိုင်ရာ စက်ကွန်ရက်များ၊ အရန်ဓာတ်အားစနစ်များနှင့် ပရိုဂရမ်အချက်အလက်များကို ကာကွယ်ပေးကာ လည်ပတ်မှုဆက်လက်မှုကို ထောက်ပံ့ပေးသည့် ခိုင်မာသော ဒေတာသိုလှောင်မှုစွမ်းရည်များ ပါဝင်ပါသည်။ ဆော့ဖ်ဝဲအင်တာဖေ့စ်သည် စက်၏ အခြေအနေ၊ လည်ပတ်မှု ပါရာမီများနှင့် ထိန်းသိမ်းမှုလိုအပ်ချက်များအကြောင်း ရှင်းလင်းသော ပုံရိပ်အချက်အလက်များကို ပေးသင့်ပါသည်။ အဆင့်မြင့်စနစ်များသည် ကွေးခွေမှုပရိုဂရမ်များ ထောင်ချီစုဆောင်းနိုင်ပြီး ပစ္စည်း၏ အသေးစိတ်ဖော်ပြချက်များနှင့် ရလဒ်များအပေါ် အခြေခံ၍ သင့်တော်သော ပါရာမီများကို အလိုအလျောက် ရွေးချယ်နိုင်ပါသည်။

စင်ဆာများ ပေါင်းစပ်ခြင်းနှင့် ပြန်လည်အကြောင်းကြားစနစ်များ

ခေတ်မီစက်များတွင် အရေးကြီးသော လည်ပတ်မှုပါရာမီများကို အချိန်နှင့်တစ်ပြေးညီ စောင့်ကြည့်သည့် စင်ဆာကွန်ရက်များကို ပေါင်းစပ်ထားပါသည်။ တည်နေရာစင်ဆာများ၊ အားတိုင်းတာသည့် ကိရိယာများနှင့် အပူချိန်စောင့်ကြည့်ကိရိယာများသည် စက်၏ စွမ်းဆောင်ရည်နှင့် အလုပ်လုပ်နေသော ပစ္စည်း၏ အခြေအနေများအကြောင်း ဆက်တိုက်ပြန်လည်အကြောင်းကြားပေးပါသည်။ ဤစင်ဆာဒေတာများက ထိန်းချုပ်မှုစနစ်အား စက်ကိရိယာများကို ပျက်စီးမှုမှ ကာကွယ်ရင်း ကွေးခွေမှုအရည်အသွေးကို တည်ငြိမ်စွာ ထိန်းသိမ်းနိုင်စေရန် အလိုအလျောက် ချိန်ညှိမှုများ ပြုလုပ်နိုင်စေပါသည်။

မျက်နှာပြင်စနစ်များနှင့် တိုင်းတာရေးကိရိယာများ ပေါင်းစပ်ခြင်းဖြင့် ပုံသွင်းစဉ်အတွင်း ဟန်ချက်ညှိထားသော ထောင့်များနှင့် အရွယ်အစားများကို စက်များဖြင့် အတည်ပြုနိုင်ပြီး စံနှုန်းမှ ဘောင်လွန်နေပါက ချက်ချင်းပြင်ဆင်နိုင်စေပါသည်။ ဤကဲ့သို့သော ပိတ်ထားသည့် ထိန်းချုပ်မှုစနစ်သည် ထုတ်လုပ်မှုအရည်အသွေးကို သိသိသာသာ မြှင့်တင်ပေးပြီး အကုန်အကျနှင့် ပြန်လည်ပြုပြင်ရမည့်လုပ်ငန်းများကို လျော့နည်းစေပါသည်။ တိုးတက်သော ဆင်ဆာစနစ်များသည် အစိတ်အပိုင်းများ၏ ပုပ်ပြားမှုပုံစံများနှင့် လည်ပတ်မှုအခြေအနေများကို စောင့်ကြည့်ခြင်းဖြင့် ပြုပြင်ထိန်းသိမ်းမှုလိုအပ်ချက်များကို ကြိုတင်ခန့်မှန်းနိုင်ပါသည်။

ကိရိယာနှင့် အလုပ်လုပ်ကိရိယာ စနစ်များ

တိကျသော ကိရိယာဒီဇိုင်း

ဝိုင်းနှင့် ကွေးပိုင်း ပုံသွင်းစက်၏ ယုံကြည်စိတ်ချရမှုသည် ၎င်း၏ ကိရိယာစနစ်များ၏ အရည်အသွေးနှင့် ဒီဇိုင်းပေါ်တွင် အလွန်အမင်း မူတည်ပါသည်။ တိကျစွာ ထုတ်လုပ်ထားသော ကွေးပိုင်းတံများ၊ ဘီးများနှင့် ပုံသွင်းကိရိယာများသည် ကွေးပိုင်းလုပ်ခြင်း စက်ဝိုင်းများစွာကို ဖြတ်သန်းပြီးနောက်တွင်ပါ အရွယ်အစားတိကျမှုကို ထိန်းသိမ်းထားရမည်ဖြစ်ပြီး ပုပ်ပြားမှုနှင့် ပုံပျက်ခြင်းမှ ခံနိုင်ရည်ရှိရမည်ဖြစ်သည်။ အဆင့်မြင့်ကိရိယာများသည် ထူးခြားသော သံမဏိနှင့် မျက်နှာပြင်ကုထုံးများကို အသုံးပြုပြီး ထူးခြားသော ခံနိုင်ရည်နှင့် တည်ငြိမ်သော စွမ်းဆောင်ရည်ကို ပေးစွမ်းနိုင်ပါသည်။

မော်ဒျူလာတင်ဆောက်မှုစနစ်များသည် ကွေးခွေမှုလိုအပ်ချက်များအလိုက် ချက်ချင်းပြောင်းလဲနိုင်စေပြီး တိကျသော တည်နေရာနှင့် တိကျမှုကို ထိန်းသိမ်းပေးပါသည်။ ကွေးခွေမှုလုပ်ငန်းစဉ်အတွင်း ပစ္စည်းအမျိုးအစား၊ အရွယ်အစားနှင့် ဂုဏ်သတ္တိများကို ကိုက်ညီစေရန် ကိရိယာများသည် ပံ့ပိုးမှုနှင့် လမ်းညွှန်မှုကို တစ်သမတ်တည်းပေးနိုင်ရပါမည်။ အမြန်ပြောင်းလဲနိုင်သော စနစ်များသည် စတင်ပြင်ဆင်မှုအချိန်ကို လျှော့ချပေးပြီး ထပ်တလဲလဲ ကိရိယာတပ်ဆင်မှုတိကျမှုကို သေချာစေကာ ထုတ်လုပ်မှုစွမ်းအားကို မြှင့်တင်ပေးပါသည်။

တိုးတက်သော ကိုင်ထားမှုနှင့် တည်နေရာသတ်မှတ်မှု

ယုံကြည်စိတ်ချရသော ပစ္စည်းကိုင်စနစ်များသည် ကွေးခွေမှုလုပ်ငန်းများအတွင်း ပစ္စည်းများကို ချောမွေ့စွာ ရွေ့လျားနိုင်စေရန် လုံခြုံသော ကိုင်ထားမှုအားကို ပေးစွမ်းပါသည်။ ပစ္စည်း၏ အရွယ်အစားနှင့် ဂုဏ်သတ္တိများ ကွဲပြားမှုကို ကိုက်ညီစေရန် ဤစနစ်များသည် တိကျမှုရှိသော တည်နေရာသတ်မှတ်မှုကို ထိန်းသိမ်းပေးရပါမည်။ တိုးတက်သော ကိုင်ထားမှုစနစ်များတွင် ဆာဗိုထိန်းချုပ်သော အားဖြည့်ကိရိယာများကို အသုံးပြုပြီး ပစ္စည်း၏ ဂုဏ်သတ္တိများနှင့် ကွေးခွေမှုလိုအပ်ချက်များအရ ကိုင်ထားမှုအားကို ချိန်ညှိပေးပါသည်။

ပေးပို့မှုစနစ်သည် ပစ္စည်းများကို တိကျစွာ ထားရှိခြင်းနှင့် အဆင့်အတန်းသတ်မှတ်ခြင်းကို ထိန်းချုပ်ပေးပြီး လုပ်ငန်းသားများ လွယ်ကူစွာ တင်သွင်းခြင်း၊ ဖယ်ရှားခြင်းလုပ်ငန်းများကို လုပ်ဆောင်နိုင်ရမည်။ အလိုအလျောက် တည်နေရာသတ်မှတ်မှုလုပ်ဆောင်ချက်များသည် လုပ်ငန်းသားများ၏ ပင်ပန်းမှုကို လျော့ကျစေပြီး တသမတ်တည်းရှိမှုကို မြှင့်တင်ပေးကာ အစိတ်အပိုင်းများ ပျက်စီးခြင်း သို့မဟုတ် စက်ပျက်စီးခြင်းကို ဖြစ်စေနိုင်သော တည်နေရာမှားခြင်းအလားအလာကို အနည်းဆုံးဖြစ်အောင် လျှော့ချပေးပါသည်။

အော်တာများနှင့် ကာကွယ်မှု အချက်အလက်များ

အားလုံးအဝန်းကျင်မှုစနစ်များ

ယုံကြည်စိတ်ချရသော ကွေးစက်များတွင် လုပ်ငန်းသားများနှင့် ပစ္စည်းကိရိယာများကို ဖြစ်နိုင်ခြေရှိသော အန္တရာယ်များမှ ကာကွယ်ပေးရန် ဘေးကင်းလုံခြုံရေး ကာကွယ်မှုအဆင့်များကို ပေါင်းစပ်ထားပါသည်။ အရေးပေါ်ရပ်တန့်ရေးစနစ်များ၊ မီးချောင်းများနှင့် ဖိအားခံ ကွန်ကရစ်ပြင်များသည် ဘေးကင်းလုံခြုံမှုမရှိသော အခြေအနေများကို ရှာဖွေတွေ့ရှိပါက ချက်ချင်း ပိတ်သိမ်းနိုင်စွမ်းကို ပေးဆောင်ပါသည်။ ဤဘေးကင်းလုံခြုံရေးစနစ်များကို အရေးပေါ်အခြေအနေများတွင် ညှိနှိုင်းပူးပေါင်း တုံ့ပြန်နိုင်ရန် စက်၏ ထိန်းချုပ်မှုစနစ်နှင့် ပေါင်းစပ်ထားရမည်ဖြစ်သည်။

ကွေးခွင်းအားလုံးကို စောင့်ကြည့်ပေးသည့် ဝန်လွန်ကာကွယ်ရေးစနစ်များသည် ကွေးခွင်းအားများကို စောင့်ကြည့်၍ ကြိုတင်သတ်မှတ်ထားသော အကန့်အသတ်များကို ကျော်လွန်ပါက အလိုအလျောက် လုပ်ဆောင်မှုများကို ရပ်တန့်ပေးပြီး အလုပ်များ၊ ကိရိယာများနှင့် စက်ပစ္စည်းများကို ပျက်စီးမှုမှ ကာကွယ်ပေးပါသည်။ ဤကာကွယ်ရေးစနစ်များသည် ပစ္စည်းအမျိုးအစားနှင့် ကွေးခွင်းလိုအပ်ချက်များနှင့် ကိုက်ညီစေရန် ချိန်ညှိနိုင်ရမည်ဖြစ်ပြီး လုံခြုံရေးအတွက် သင့်တော်သော အကွာအဝေးများကို ထိန်းသိမ်းထားရမည်ဖြစ်သည်။ မျက်စိဖြင့်မြင်နိုင်သောနှင့် နားဖြင့်ကြားနိုင်သော သတိပေးစနစ်များသည် အရေးပေါ်အခြေအနေများ မဖြစ်မီ လုပ်သားများအား အန္တရာယ်ရှိနိုင်သော အခြေအနေများကို သတိပေးပေးပါသည်။

ပစ္စည်းကာကွယ်ရေးစနစ်များ

တိုးတက်သော ကာကွယ်ရေးစနစ်များသည် ပစ္စည်းပျက်စီးခြင်း၊ အပူလွန်ခြင်း သို့မဟုတ် ချို့ယွင်းမှုများကို စောင့်ကြည့်ပေးပြီး ပစ္စည်းပျက်စီးခြင်း သို့မဟုတ် ယုံကြည်စိတ်ချရမှု ကျဆင်းလာနိုင်သော အခြေအနေများကို ကာကွယ်ပေးပါသည်။ အပူချိန်စောင့်ကြည့်ကိရိယာများ၊ တုန်ခါမှုစောင့်ကြည့်ကိရိယာများနှင့် ဖိအားမျှင်များသည် ပြုပြင်ထိန်းသိမ်းမှုလိုအပ်သော ပြဿနာများကို စောစီးစွာ သတိပေးပေးပါသည်။ ဤစနစ်များသည် ပြင်းထန်သော ပျက်စီးမှုများကို ကာကွယ်ပေးပြီး ရပ်နားမှုကြာရှည်ခြင်းနှင့် ပြုပြင်စရိတ်များကို ကာကွယ်ပေးပါသည်။

အလိုအလျောက်သုတ်ဆီစနစ်များသည် အရေးကြီးသော အစိတ်အပိုင်းများသည် လူသားမှ လက်ခံထားခြင်းမရှိဘဲ သင့်တော်သော ထိန်းသိမ်းမှုကို ရရှိစေပါသည်။ ဤစနစ်များကို အကောင်းဆုံး အကွာအဝေးတွင် သုတ်ဆီပမာဏများကို တိကျစွာ ပေးပို့ရန် အစီအစဉ်ဆွဲနိုင်ပြီး အစိတ်အပိုင်းများ၏ သက်တမ်းကို ရှည်လျားစေကာ စွမ်းဆောင်ရည်ကို တည်ငြိမ်စေပါသည်။ ညစ်ညမ်းမှု ဖော်ထုတ်မှုစနစ်များသည် ညစ်ပတ်သော အရည်များ သို့မဟုတ် ဖိသိပ်ထားသော လေကြောင့် ဖြစ်ပေါ်လာသော ပျက်စီးမှုမှ ဟိုက်ဒရောလစ်နှင့် ပန်ကာစနစ် အစိတ်အပိုင်းများကို ကာကွယ်ပေးပါသည်။

ထိန်းသိမ်းမှုနှင့် ဝန်ဆောင်မှုပေးနိုင်မှု လက္ခဏာများ

ထိန်းသိမ်းမှုအတွက် လွယ်ကူစွာ ဝင်ရောက်နိုင်သော ဒီဇိုင်း

ယုံကြည်စိတ်ချရသော စက်များကို ထိန်းသိမ်းမှု လွယ်ကူစွာ ဝင်ရောက်နိုင်ခြင်းကို အဓိကထား၍ ဒီဇိုင်းထုတ်ထားပြီး ဖယ်ရှားနိုင်သော ပြားများ၊ ဗျူဟာမြောက် တည်နေရာများတွင် တပ်ဆင်ထားသော ဝန်ဆောင်မှု အမှတ်များနှင့် ပုံမှန်ထိန်းသိမ်းမှု လုပ်ငန်းများကို လွယ်ကူစေသည့် ရှင်းလင်းသော အစိတ်အပိုင်း အမှတ်အသားများ ပါဝင်ပါသည်။ စက်၏ စီမံပုံသည် နည်းပညာပညာရှင်များအတွက် အစိတ်အပိုင်းအားလုံးကို ဘေးကင်းစွာ ဝင်ရောက်နိုင်ရန် လုံလောက်သော နေရာကို ပေးသင့်ပြီး ပုံမှန် ဝန်ဆောင်မှု လုပ်ငန်းစဉ်များအတွင်း အထူးကိရိယာများ သို့မဟုတ် ပစ္စည်းကိရိယာများ အသုံးပြုမှုကို အနည်းဆုံးဖြစ်အောင် လျှော့ချပေးသင့်ပါသည်။

စက်ပစ္စည်း၏ အခြေအနေနှင့် ထိန်းသိမ်းရန် လိုအပ်ချက်များကို အသေးစိတ်ဖော်ပြပေးသည့် စနစ်များဖြစ်ပြီး နည်းပညာပိုင်းဆိုင်ရာ ဝန်ထမ်းများအနေဖြင့် ပြဿနာများကို မြန်ဆန်စွာနှင့် တိကျစွာ ရှာဖွေဖြေရှင်းနိုင်ရန် ကူညီပေးသည်။ ကိုယ်ပိုင်စစ်ဆေးမှုစွမ်းရည်များက အဖြစ်များသော ပြဿနာများကို အလိုအလျောက် ရှာဖွေဖော်ထုတ်ပေးပြီး ပြဿနာဖြေရှင်းခြင်းလုပ်ငန်းစဉ်များကို လုပ်ဆောင်ရာတွင် စက်လည်ပတ်သူများအား လမ်းညွှန်ပေးကာ စက်ရပ်တန့်မှုကာလနှင့် ဝန်ဆောင်မှုကုန်ကျစရိတ်များကို လျှော့ချပေးသည်။ စနစ်တကျ ပြုလုပ်ထားသော ထိန်းသိမ်းမှုစာရွက်စာတမ်းများနှင့် ဗီဒီယိုလမ်းညွှန်များက နည်းပညာပိုင်းဝန်ထမ်းများ၏ စွမ်းရည်များကို မြှင့်တင်ပေးပြီး လေ့ကျင့်ရေးလိုအပ်ချက်များကို လျှော့ချပေးသည်။

ပါဝင်ပစ္စည်းများ၏ အရည်အသွေးနှင့် သက်တမ်း

နာမည်ကြီး ထုတ်လုပ်သူများထံမှ အရည်အသွေးမြင့် ပါဝင်ပစ္စည်းများကို ရွေးချယ်ခြင်းသည် စက်ပစ္စည်း၏ ယုံကြည်စိတ်ချရမှုနှင့် သက်တမ်းအပေါ် သက်ရောက်မှုရှိသည်။ စက်မှုလုပ်ငန်းအသုံးချမှုများတွင် အောင်မြင်မှုမှတ်တမ်းရှိသော နာမည်ကြီး ပေးသွင်းသူများထံမှ အဆင့်မြင့် ဘီယာ၊ ပိတ်ဆို့မှုပစ္စည်းများ၊ လျှပ်စစ်ပစ္စည်းများနှင့် သုံးစွဲပျက်စီးသည့် အစိတ်အပိုင်းများကို ရယူသင့်သည်။ ပါဝင်ပစ္စည်းများကို စံသတ်မှတ်ခြင်းဖြင့် ထိန်းသိမ်းမှုကို ပိုမိုလွယ်ကူစေပြီး ကုန်ကြမ်းစာရင်းလိုအပ်ချက်များကို လျှော့ချပေးကာ ပါဝင်ပစ္စည်းများ ရရှိမှုကို သေချာစေသည်။

အဆိုပါ ကွာလီဖိုးနီးယား စက်ရုပ်များသည် ခြေထောက် ဝတ်စုံများကို အသုံးပြု၍ လူသားများနှင့် အလားသဏ္ဍာန်တူသော လှုပ်ရှားမှုများကို ပြုလုပ်နိုင်ပြီး ခြေထောက် လှုပ်ရှားမှု ထိန်းချုပ်မှု စနစ်များကို အသုံးပြုကာ လမ်းလျှောက်ခြင်း၊ ခုန်ခြင်းနှင့် ခွက်ခြင်းတို့ကဲ့သို့သော လှုပ်ရှားမှုများကို အကောင်အထည်ဖော်ပေးပါသည်။

မေးလေ့ရှိသောမေးခွန်းများ

အရည်အသွေးမြင့် စက်ဘီးနှင့် ကွေးခွေမှု စက်တစ်လုံး၏ အသက်တာကို မည်မျှမျှ မျှော်လင့်နိုင်ပါသလဲ

သင့်တော်သော ထိန်းသိမ်းမှုနှင့် ဂရုစိုက်မှုဖြင့် အရည်အသွေးမြင့် စက်ဘီးနှင့် ကွေးခွေမှု စက်တစ်လုံးသည် ပုံမှန်အားဖြင့် ၁၅ မှ ၂၅ နှစ်အထိ ယုံကြည်စွာ လည်ပတ်နိုင်ပါသည်။ အမှန်တကယ် အသက်တာမှာ အသုံးပြုမှု အပြင်းအထန်၊ ကုန်ကြမ်းအမျိုးအစားများ၊ ထိန်းသိမ်းမှုအရည်အသွေးနှင့် လည်ပတ်မှု ပတ်ဝန်းကျင်အခြေအနေများကဲ့သို့သော အချက်များပေါ်တွင် မူတည်ပါသည်။ ပုံမှန် ကာကွယ်ရေး ထိန်းသိမ်းမှုများဖြင့် အလတ်စား ထုတ်လုပ်မှု ပတ်ဝန်းကျင်များတွင် အသုံးပြုသော စက်များသည် မျှော်လင့်ထားသော ဝန်ဆောင်မှု သက်တမ်းကို သိသိသာသာ ကျော်လွန်တတ်ပါသည်။

ကွေးခွေမှု စက်များတွင် ဟိုက်ဒရောလစ် စနစ်များကို မည်မျှကြာခြင်း ပြုပြင်ထိန်းသိမ်းသင့်ပါသလဲ

အကွေ့ပေးစက်များတွင် ဟိုက်ဒရောလစ်စနစ်များကို အလုပ်လုပ်ချိန် ၁,၀၀၀ မှ ၂,၀၀၀ နာရီ (သို့) တစ်နှစ်လျှင် တစ်ကြိမ်၊ ဘယ်အချိန်မှာမဆို ပိုမိုစောသည့်အချိန်တွင် စနစ်တကျ ဝန်ဆောင်မှုပေးသင့်ပါသည်။ ၎င်းတွင် ဟိုက်ဒရောလစ်အရည် ဓာတ်ခွဲခြင်း၊ စစ်ထုတ်စီးပွားလဲလှယ်ခြင်း၊ ဖိအားစမ်းသပ်ခြင်းနှင့် ပိတ်ဆို့မှုစစ်ဆေးခြင်းတို့ ပါဝင်ပါသည်။ အရည်အချိန်၊ အပူချိန်နှင့် ဖိအားညွှန်ပြချက်များကို နေ့စဉ်စစ်ဆေးခြင်းဖြင့် ပြင်ဆင်မှုအတွက် အဓိကလိုအပ်ချက်များ မဖြစ်မချင်း ပြဿနာများကို စောစီးစွာ ဖော်ထုတ်နိုင်ပါသည်။

အကွေ့ပေးခြင်း၏ တိကျမှုနှင့် ထပ်တူတိကျမှုကို ဘယ်အချက်တွေက အဓိက သက်ရောက်မှုရှိပါသလဲ

အကွေ့ပေးခြင်း၏ တိကျမှုနှင့် ထပ်တူတိကျမှုကို စက်တံဆိပ်၏ မာကျောမှု၊ ကိရိယာများ၏ တိကျမှု၊ ထိန်းချုပ်မှုစနစ်၏ ရှုပ်ထွေးမှုနှင့် သင့်တော်သော ကယ်လီဘရေးရှင်းပြုလုပ်မှုတို့က အဓိက သက်ရောက်မှုရှိပါသည်။ အပူချိန်ပြောင်းလဲမှု၊ တုန်ခါမှုနှင့် ပစ္စည်း၏ ဂုဏ်သတ္တိများ ပြောင်းလဲမှုကဲ့သို့သော ပတ်ဝန်းကျင်ဆိုင်ရာ အချက်များကလည်း ရလဒ်များကို သက်ရောက်မှုရှိပါသည်။ ပုံမှန်ကယ်လီဘရေးရှင်းပြုလုပ်ခြင်း၊ ကိရိယာများကို သင့်တော်စွာ ထိန်းသိမ်းခြင်းနှင့် တသမတ်တည်းရှိသော လည်ပတ်မှုလုပ်ထုံးလုပ်နည်းများက စက်၏ ဝန်ဆောင်မှုသက်တမ်းတစ်လျှောက် အကောင်းဆုံးတိကျမှုကို ထိန်းသိမ်းရန် ကူညီပေးပါသည်။

ဟောင်းနွမ်းသော အကွေ့ပေးစက်များကို ခေတ်မီထိန်းချုပ်မှုစနစ်များဖြင့် မွမ်းမံနိုင်ပါသလား

ခိုင်မာသောစက်ပိုင်းဆိုင်ရာအခြေခံအုတ်မြစ်များပါရှိသော ရှေးယခင်ကွေးညွှတ်စက်အများအပြားကို ခေတ်မီထိန်းချုပ်မှုစနစ်များ၊ ဆာဗိုဒရိုက်များနှင့် ဘေးကင်းရေးကိရိယာများဖြင့် အောင်မြင်စွာ အဆင့်မြှင့်တင်နိုင်ပါသည်။ ဤပြန်လည်ပြင်ဆင်မှုသည် စက်၏သက်တမ်းကို သက်တမ်းတိုးစေပြီး တိကျမှု၊ ကုန်ထုတ်စွမ်းအားနှင့် ဘေးကင်းမှုကို သိသိသာသာ တိုးတက်စေနိုင်သည်။ ဖြစ်နိုင်ချေသည် စက်၏ဖွဲ့စည်းပုံအခြေအနေ၊ ရှိပြီးသားလျှပ်စစ်စနစ်များနှင့် မူလထုတ်လုပ်သူ သို့မဟုတ် အထူးပြုကုမ္ပဏီများထံမှ တွဲဖက်အဆင့်မြှင့်ထားသော အစိတ်အပိုင်းများရရှိနိုင်မှုအပေါ် မူတည်ပါသည်။

အကြောင်းအရာများ

- ဖွဲ့စည်းပုံအခြေခံမူနှင့် ကွန်ရိုးဒီဇိုင်း

- ဟိုက်ဒရောလစ်နှင့် မောင်းနှင်မှုစနစ်များ

- ထိန်းချုပ်မှုစနစ်များနှင့် အလိုအလျောက်လုပ်ဆောင်ခြင်း လုပ်ဆောင်ချက်များ

- ကိရိယာနှင့် အလုပ်လုပ်ကိရိယာ စနစ်များ

- အော်တာများနှင့် ကာကွယ်မှု အချက်အလက်များ

- ထိန်းသိမ်းမှုနှင့် ဝန်ဆောင်မှုပေးနိုင်မှု လက္ခဏာများ

-

မေးလေ့ရှိသောမေးခွန်းများ

- အရည်အသွေးမြင့် စက်ဘီးနှင့် ကွေးခွေမှု စက်တစ်လုံး၏ အသက်တာကို မည်မျှမျှ မျှော်လင့်နိုင်ပါသလဲ

- ကွေးခွေမှု စက်များတွင် ဟိုက်ဒရောလစ် စနစ်များကို မည်မျှကြာခြင်း ပြုပြင်ထိန်းသိမ်းသင့်ပါသလဲ

- အကွေ့ပေးခြင်း၏ တိကျမှုနှင့် ထပ်တူတိကျမှုကို ဘယ်အချက်တွေက အဓိက သက်ရောက်မှုရှိပါသလဲ

- ဟောင်းနွမ်းသော အကွေ့ပေးစက်များကို ခေတ်မီထိန်းချုပ်မှုစနစ်များဖြင့် မွမ်းမံနိုင်ပါသလား