| Place of Origin: |

Jining City, Shandong Province |

| Brand Name: |

XINXINGDA |

| Model Number: |

32C |

| Minimum Order Quantity: |

1 |

| Packaging Details: |

According to the product, smaller wooden box packaging |

| Delivery Time: |

30-90days,depending on specific customization requirements |

| Payment Terms: |

Shipment after receiving the final payment |

Description:

The "sheet reinforcement" in the name "CNC Steel Sheet Rebar Stirrup Bender" may be a misspelling or a local term for "sheet reinforcement" or "reinforcement." The standard, universal name should be "CNC Steel Sheet Rebar Stirrup Bender."

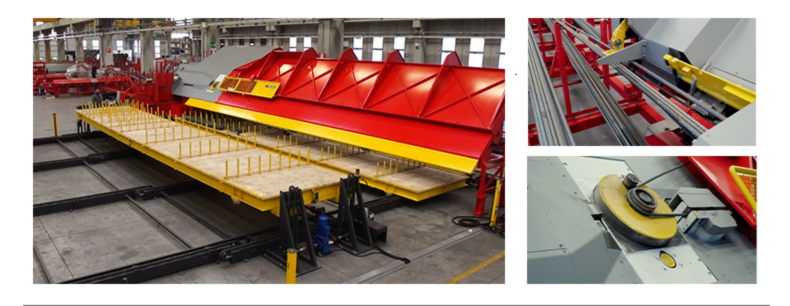

This type of equipment is an indispensable core component of modern rebar processing. It is specifically designed to efficiently and accurately bend rebar to create stirrups in various shapes (such as rectangular, square, polygonal, circular, and special-shaped). It is widely used in beams, columns, and slabs in buildings, bridges, tunnels, and other projects.

construction sites

Steel bar bending processing

Specifications:

| XDWG-32C CNC Bar Bending and coiling Machine |

| Processing diameter of a single reinforcing bar(mm) |

10--32 |

| Diameter of double-root reinforcing bars processing(mm) |

10--20 |

| Maximum bending angle(°) |

±180 |

| Maximum traction speed(m/min) |

100 |

| Maximum bending speed(°/sec) |

1200 |

| Length accuracy(mm/m) |

±1 |

| Angle accuracy(°) |

±1 |

| Rebar efficiency(t/h) |

40/20 |

| Pneumatic component brand |

AirTAC |

| Servo motor brand |

Huichuan |

| Low-voltage electrical appliance brand |

Schneider Electric |

| hydraulic system |

have |

| Hydraulic cooling system |

have |

| equipment power(KW) |

60 |

| Number of equipment operators |

1 |

| floor space(m*m) |

29*12 |

A multi-level hopper with an end-mounted magnetic loading mechanism ensures continuous production without interruption.

An optional overhead mold storage system with a robotic arm allows for automatic mold changes.

A 12-meter material receiving rack enables continuous production of 12-meter internal stirrups and sheet reinforcement.

Multi-level finished product trolleys store finished products of different specifications.

Multiple graphics can be stored for direct access.

Tag:

Independent research and development design, quality assurance

High-end, efficient and high-precision

Meet your customized needs