| Place of Origin: |

Jining City, Shandong Province |

| Brand Name: |

XINXINGDA |

| Model Number: |

40S |

| Minimum Order Quantity: |

1 |

| Packaging Details: |

According to the product, smaller wooden box packaging |

| Delivery Time: |

30-90days,depending on specific customization requirements |

| Payment Terms: |

Shipment after receiving the final payment |

Description:

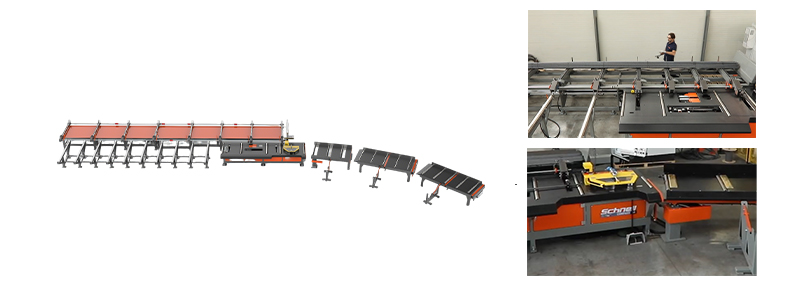

The "All-in-One Bending Machine" is a specialized industrial processing device designed to automatically, efficiently, and precisely bend metal profiles (such as round tubes, square tubes, flat steel, angle steel, and channel steel) or sheet metal into circles, arcs, or other complex planar curves.

As the name suggests, it integrates both "bending" and "bending" functions into a single device, eliminating the need for switching between multiple processes or machines, significantly improving production efficiency and processing accuracy.

steel bar processing plant

Specifications:

| XDWH40S integrated Machine for Bending circies and Arcs |

| Inner ring diameter range(mm) |

400-2500 |

| Bar diameter range(mm) |

12-40 |

| Material loading method |

Automatic |

| Inner ring disengagement method |

Automatic |

| Inner ring transfer and stacking method |

Automatic |

| Total output /20 hours(°) |

600 |

| total power(KW) |

20 |

| Pneumatic component brand |

AirTAC |

| Servo motor brand |

Huichuan |

| Low-voltage electrical appliance brand |

Schneider Electric |

| Number of equipment operators |

1 |

| floor space(m*m) |

22.4*14 |

A flat loading mechanism is used for automatic counting and loading.

The raw bar material is sheared and then finished.

Laser detection of the rebar profile automatically locates the longitudinal ribs, ensuring consistent curved dimensions.

Automatic unloading of finished curved rebar.

Automatic round bend welding.

A truss manipulator automatically grabs the inner coils of the rebar for transport.

Finished rebar inner coils are automatically stacked and palletized.

The level of automation facilitates remote task assignment and oversight.

Tag:

Independent research and development design, quality assurance

High-end, efficient and high-precision

Meet your customized needs