| Place of Origin: |

Jining City, Shandong Province |

| Brand Name: |

XINXINGDA |

| Model Number: |

1500S |

| Minimum Order Quantity: |

1 |

| Packaging Details: |

According to the product, smaller wooden box packaging |

| Delivery Time: |

30-90days,depending on specific customization requirements |

| Payment Terms: |

Shipment after receiving the final payment |

Description:

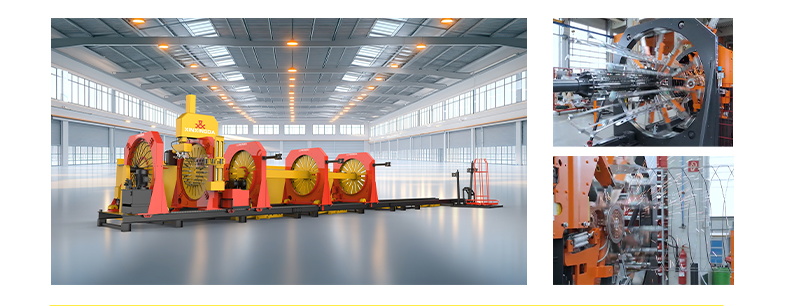

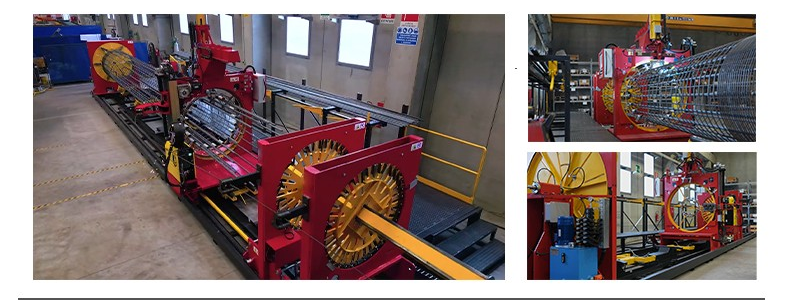

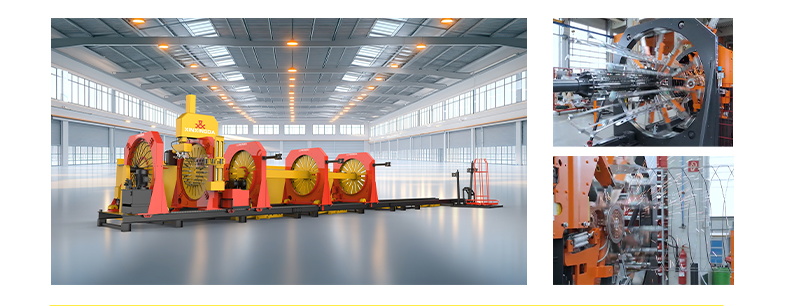

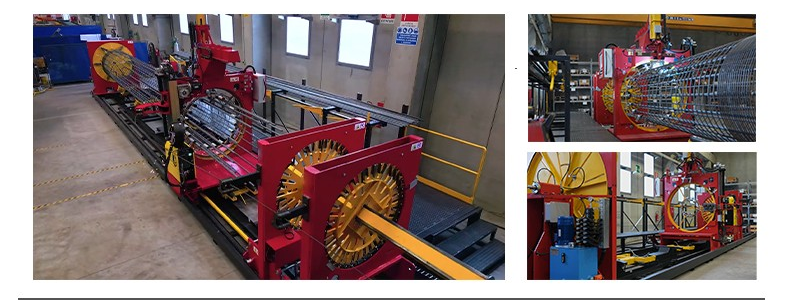

The rebar cage roll welding machine is a specialized, highly automated and efficient piece of equipment primarily used for the large-scale, standardized production of rebar cages for reinforced concrete structures (especially pile foundations, bridge piers, etc.).

The rebar cage roll welding machine is a crucial piece of equipment in the industrialization and standardization of modern construction. Through its high degree of automation, it addresses the challenges of traditional rebar cage production, including low efficiency, high quality variability, high labor costs, and numerous safety hazards. It is particularly well-suited for large-scale infrastructure projects requiring large quantities of high-quality rebar cages, making it an indispensable "rebar cage manufacturing factory" for pile foundation projects.

steel bar processing plant

Specifications:

| XDGHJ-1500S telescopic and variable diameter steel cage roll welding machine |

| Steel cage pile diameter(mm) |

Ф250-1500mm |

|

| Reinforcement cage length (m) |

12m |

Customizable |

| The weight of the steel cage |

5000Kg |

|

| Diameter of the coil rib |

Ф5-14mm |

|

| Spacing of stirrups |

20-500mm |

|

| Diameter of the main reinforcement |

12-40mm |

|

| The locking method of the main tendons |

Automatic |

Hydraulic |

| Automatic diameter change |

have |

Hydraulic |

| Welding method |

Automatic |

Top-mounted welding torch |

| Operator |

One person |

|

| Pressure of the hvdraulic station |

16Mpa |

|

| Total power |

35KW |

|

| Land area |

18m*7m |

|

| CNC steel cage rolling welding machine |

|

XDGH-1500 |

XDGH-1800 |

XDGH-2000 |

XDGH-2200 |

XDGH-2500 |

XDGH-3000 |

| Steel cage pile diameter(mm) |

500-1500 |

500-1800 |

600-2000 |

600-2200 |

800-2500 |

800-3000 |

| Reinforcement cage length (m) |

12 (customizable) |

| Main reinforcement diameter(mm) |

Ф16-50 |

| Reinforcement diameter (mm) |

Ф5-16 |

| Welding method for reinforcing bars |

Welding robotic arm or manual labor |

| Reinforcement spacing |

≤300 |

| Hydraulic pressure |

≤16 |

| Gas source pressure |

≤0.8 (gas for automatic welding) |

| KW.h |

16 |

18 |

23 |

23 |

25 |

28 |

| Welding power |

30 (dual gun automatic welding) |

| Be equipped with operators |

1-2 people (double-gun automatic welding); 2 to 4 people (manual welding) |

| Production efficiency |

8 sessions /10 hours (actual reference: on-site environment) |

| Floor space (automatic welding without side wings) |

28*6 |

28*6 |

28*6.5 |

28*7 |

28*9 |

28*11 |

| Floor space (with side wing automatic welding) |

28*8.5 |

28*8.5 |

28*9 |

28*9.5 |

28*11.5 |

28*13.5 |

High processing speed: material preparation, seam welding, reinforcement bar installation, detector tube installation, guide block installation, and more, all with extremely high efficiency.

Stable and reliable processing quality: Thanks to the use of CNC mechanized operations, the spacing between the main and winding bars is uniform, the diameter of the rebar cage is consistent, and product quality fully meets regulatory requirements. In practice, when manually producing rebar cages, the project supervisor would conduct almost daily on-site inspections. However, with the introduction of machine processing, supervisor inspections are virtually eliminated for mechanized rebar cages.

Tie bars do not require overlap, saving 1.5% of material compared to manual processing and reducing construction costs.

Because the main bars are evenly distributed around the circumference, overlapping multiple rebar cages is easy, saving lifting time.

Mechanized processing of steel rebar cages ensures comprehensive quality control.

Finished rebar inner coils are automatically stacked and palletized.

The level of automation facilitates remote task assignment and oversight.

Tag:

Independent research and development design, quality assurance

High-end, efficient and high-precision

Meet your customized needs