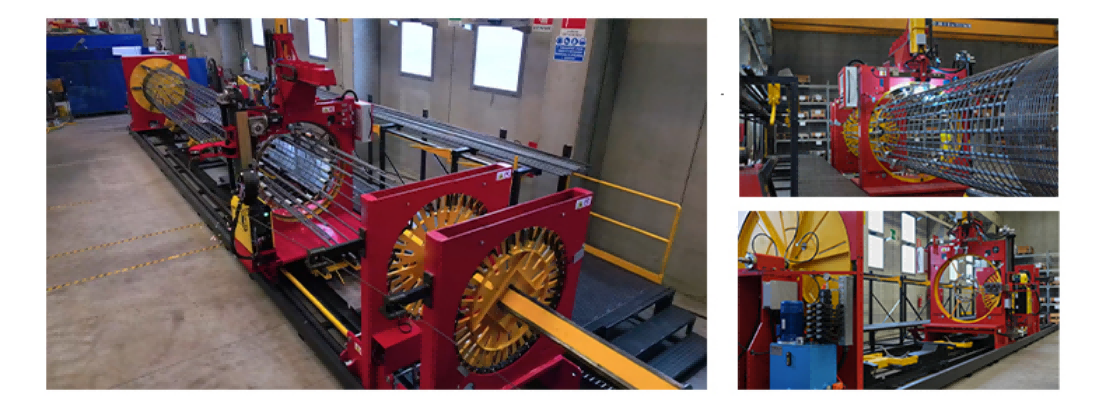

Rebar cage roll welding machine

Pile cage roll welding machine

Pile foundation cage welding machine

Steel cage welding

Can process special-shaped shapes such as circular, triangular, quadrilateral, etc.

Place of Origin: |

Jining City, Shandong Province |

Brand Name: |

XINXINGDA |

Model Number: |

GHJ2500 |

Certification: |

|

Minimum Order Quantity: |

1 |

Price: |

|

Packaging Details: |

According to the product, smaller wooden box packaging |

Delivery Time: |

30-90days,depending on specific customization requirements |

Payment Terms: |

Shipment after receiving the final payment |

Supply Ability: |

Description:

The rebar cage roll welding machine is a specialized, highly automated and efficient piece of equipment primarily used for the large-scale, standardized production of rebar cages for reinforced concrete structures (especially pile foundations, bridge piers, etc.).

The rebar cage roll welding machine is a crucial piece of equipment in the industrialization and standardization of modern construction. Through its high degree of automation, it addresses the challenges of traditional rebar cage production, including low efficiency, high quality variability, high labor costs, and numerous safety hazards. It is particularly well-suited for large-scale infrastructure projects requiring large quantities of high-quality rebar cages, making it an indispensable "rebar cage manufacturing factory" for pile foundation projects.

Applications:

construction sites

steel bar processing plant

Specifications:

| CNC steel cage rolling welding machine | ||||||

| Parameter | XDG-1500 | XDG-1800 | XDG-2000 | XDG-2200 | XDG-2500 | XDG-3000 |

| Steel cage pile diameter (mm) | 500-1500 | 500-1800 | 600-2000 | 600-2200 | 800-2500 | 800-3000 |

| Reinforcement cage length (m) | 12 (customizable) | |||||

| Main reinforcement diameter (mm) | Φ16-50 | |||||

| Reinforcement diameter (mm) | Φ5-16 | |||||

| Welding method for reinforcing bars | Welding robotic arm or manual labor | |||||

| Reinforcement spacing | ≤300 | |||||

| Hydraulic pressure | ≤16 | |||||

| Gas source pressure | ≤0.8 (gas for automatic welding) | |||||

| KW.h | 16 | 18 | 23 | 23 | 25 | 28 |

| Welding power | 30 (dual gun automatic welding) | |||||

| Be equipped with operators | 1-2 people (double-gun automatic welding); 2 to 4 people (manual welding) | |||||

| Production efficiency | 8 sessions /10 hours (actual reference: on-site environment) | |||||

| Floor space (automatic welding without side wings) | 28*6 | 28*6 | 28*6.5 | 28*7 | 28*9 | 28*11 |

| Floor space (with side wing automatic welding) | 28*8.5 | |||||

| XDZD-GHJ2500 Fully automatic Steel cage Workstation | ||

| Steel cage pile diameter | Φ800-2500mm | |

| Rebar cage length | 12m | |

| Main reinforcement diameter | Φ18-40mm | |

| diameter of coiled reinforcement | Φ8-16mm | |

| Stirrup spacing | 20-500mm | |

| Main reinforcement type | Single main reinforcement, double main reinforcement | Customized double main reinforcement |

| Type of reinforcing bar | Single-wrap reinforcement, double-wrap reinforcement | |

| Hydraulic station pressure | 16Mpa | |

| Gas source pressure | 0.8Mpa | |

| Operators | 1 person | |

| Production efficiency | 13 sessions/10 hours | 100KW welding |

| 12 meters/section | ||

| Total power | 30KW | |

| Area | 30m*8.5m | |

Competitive Advantage:

Precise automatic welding of main reinforcement bars and inner ring: 100% automatic detection of welds; automatic memory matching of main reinforcement bar length and position; automatic dual-gun welding of reinforcing bars and main reinforcement bars; automatic switching between different steel cage specifications; automatic detachment and transfer of steel cages, etc. In short, it is intelligent, stable, and efficient.

Tag:

Independent research and development design, quality assurance

High-end, efficient and high-precision

Meet your customized needs

Copyright © 2026 Shandong synstar Intelligent Technology Co., Ltd. All rights reserved. - Privacy Policy