The company has strong technical strength. All members of the R&D team have a bachelor's degree or above, with over 50% holding a postgraduate degree. There are 4 engineers with over 10 years of experience in the development of steel bar processing equipment

Company Area

The Proportion of Postgraduate Students in The Company

Workers With Over 10 Years of Industry Experience

The Products Are Sold to the Country

1 2 3 4 5 6

1 2 3 4 5 6

Super Strong Specification Compatibility

The single machine supports the processing of all specifications of steel bars with diameters ranging from Φ6 to 50mm, and the one-time forming qualification rate of complex irregular parts reaches 99.8%

In-depth Practice of Industry 4.0

The equipment is equipped with an AI process optimization system that analyzes the properties of steel in real time and automatically adjusts parameters. Compared with traditional equipment, it saves 15% of materials and improves energy efficiency by 25%

Ecological-level Customized Services

We offer a full-chain solution covering equipment selection, intelligent factory planning, and ERP/MES system integration, empowering customers to build smart steel bar processing factories

Digital Twin Pre-verification

By applying virtual debugging technology, over 2,000 hours of digital simulation production were completed before delivery to ensure that the customized equipment was effective upon commissioning

Lifetime Technical Escort

Establish a doctoral-level remote diagnosis center, equipped with an expert team to respond 24 hours a day, and provide intelligent operation and maintenance support throughout the entire life cycle of the equipment

Top-notch R&D team

The core technical team is led by postdoctoral researchers, with 50% of its members having over ten years of experience. They have obtained multiple national patents, laying a solid technical barrier

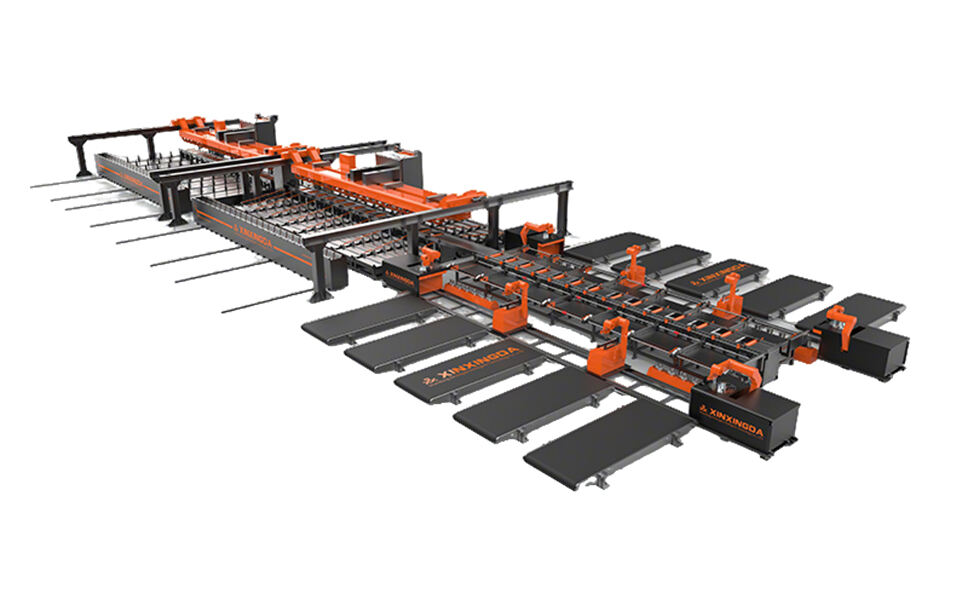

In the bar and steel bar bending equipment, the multi-joint robotic arm is creatively introduced, matched with flexible gripping tooling, which can easily and efficiently realize the simultaneous positioning and processing of multiple steel bars, and realize the multi-functional unmanned loading and unloading

Read More

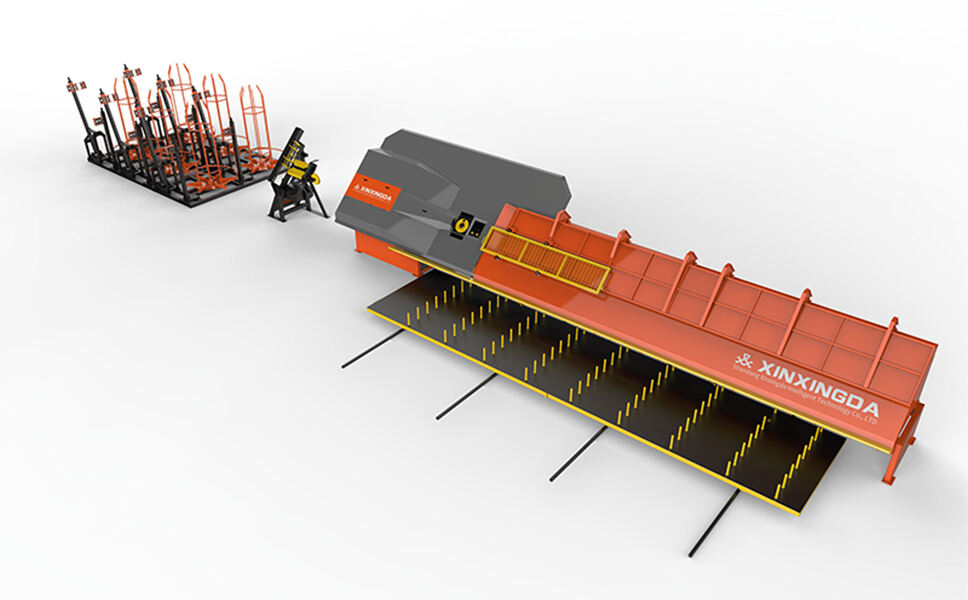

This is an automated equipment that combines straightening, bending and shearing. The machine automatically completes the entire processing process from steel bar raw materials to formed stirrups, eliminating the need for manual measurement and manual bending. It is widely loved by international friends.

Read More

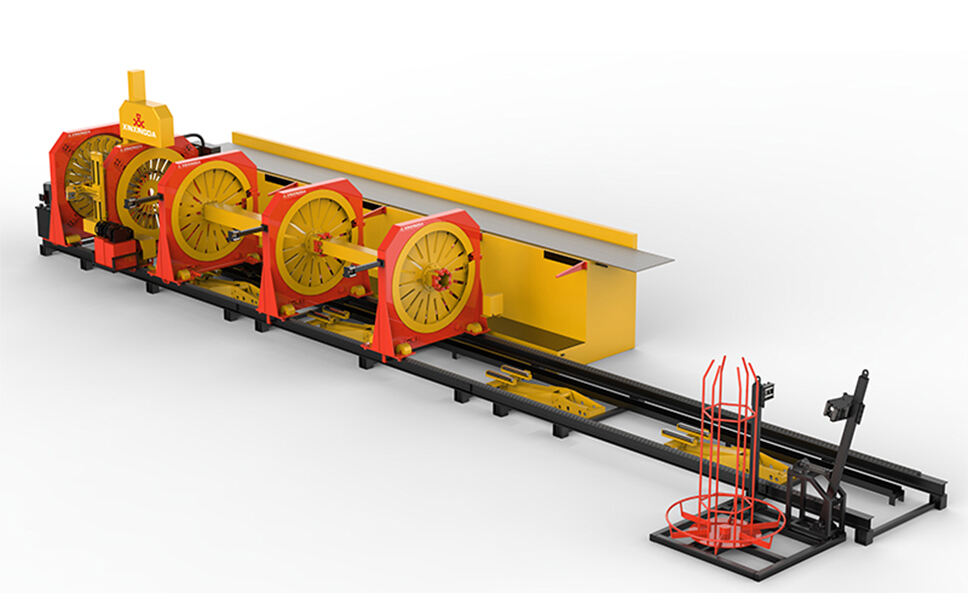

Our CNC rebar cage welding machine utilizes an advanced CNC control system, integrating automatic feeding, straightening, bending, winding, and welding functions. Simply inputting preset parameters allows the machine to continuously and stably produce high-quality rebar cages for bridge pile foundations and building columns. Our CNC rebar cage welding machine is more than just a machine; it's a tireless, high-precision, and cost-effective production team member.

Read More

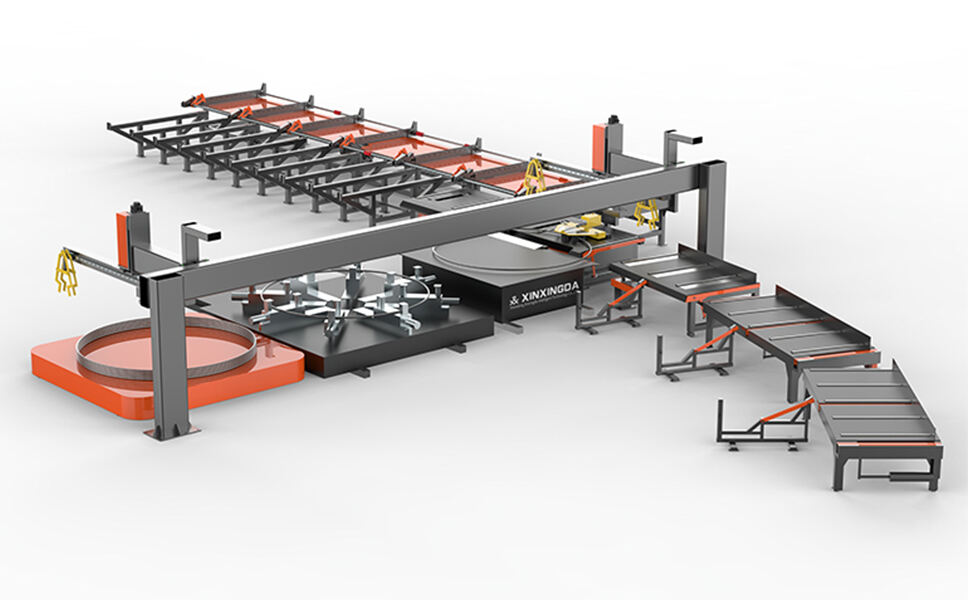

This high-precision CNC forming machine integrates multiple functions, including precision bending, free bending, straightening, feeding, and cutting. Using advanced CNC control systems and servo drive technology, it can continuously process straight materials into various complex flat or three-dimensional arc shapes with just one clamping.

Read More

Copyright © 2026 Shandong synstar Intelligent Technology Co., Ltd. All rights reserved. - Privacy Policy