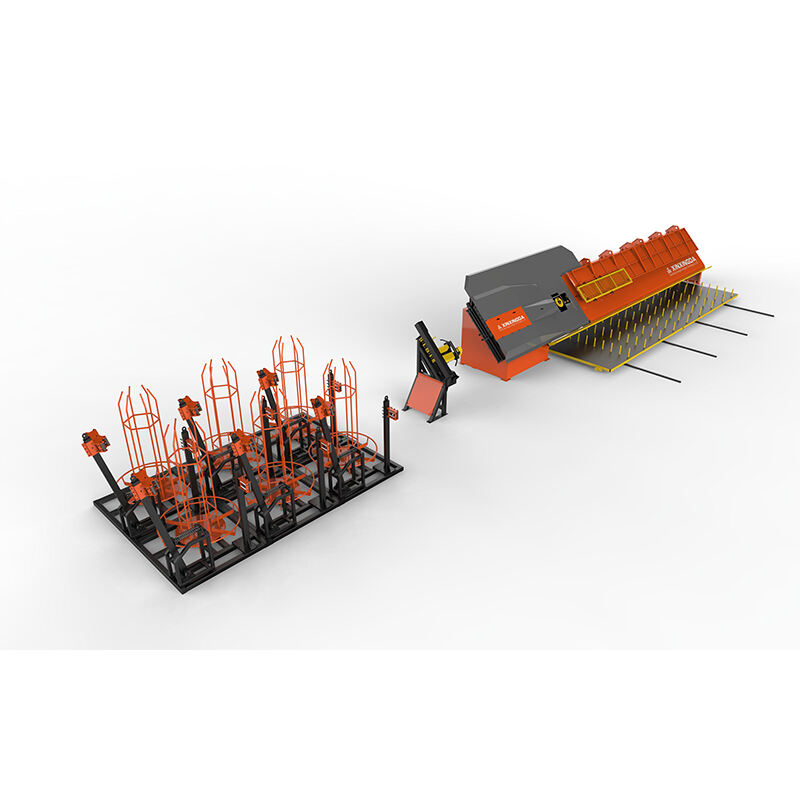

ਆਧੁਨਿਕ ਨਿਰਮਾਣ ਅਤੇ ਉਤਪਾਦਨ ਖੇਤਰ ਵਿੱਚ, ਭਾਰੀ ਡਿਊਟੀ ਮੈਟਲ ਫੈਬਰੀਕੇਸ਼ਨ ਪ੍ਰੋਜੈਕਟਾਂ 'ਤੇ ਕੰਮ ਕਰਦੇ ਸਮੇਂ ਸਹੀਤਾ ਅਤੇ ਕੁਸ਼ਲਤਾ ਸਭ ਤੋਂ ਮਹੱਤਵਪੂਰਨ ਹੈ। ਰੀ-ਬਾਰ, ਸਟ੍ਰਕਚਰਲ ਸਟੀਲ ਅਤੇ ਹੋਰ ਨਿਰਮਾਣ ਸਮੱਗਰੀ ਦੀਆਂ ਵੱਡੀਆਂ ਮਾਤਰਾਵਾਂ ਨਾਲ ਕੰਮ ਕਰਨ ਵਾਲੀਆਂ ਸੁਵਿਧਾਵਾਂ ਲਈ ਇੱਕ ਵੱਡੇ ਪੈਮਾਨੇ 'ਤੇ ਬੈਂਡਿੰਗ ਮਸ਼ੀਨ ਇੱਕ ਮਹੱਤਵਪੂਰਨ ਨਿਵੇਸ਼ ਹੈ। ਭਰੋਸੇਯੋਗ ਉਪਕਰਣਾਂ ਨੂੰ ਘੱਟ ਗੁਣਵੱਤਾ ਵਾਲੇ ਵਿਕਲਪਾਂ ਤੋਂ ਵੱਖ ਕਰਨ ਵਾਲੀਆਂ ਮੁੱਢਲੀਆਂ ਵਿਸ਼ੇਸ਼ਤਾਵਾਂ ਨੂੰ ਸਮਝਣਾ ਕੰਮਕਾਜੀ ਉਤਪਾਦਕਤਾ, ਪ੍ਰੋਜੈਕਟ ਦੇ ਸਮਾਂ-ਸੀਮਾ ਅਤੇ ਕੁੱਲ ਮੁਨਾਫ਼ੇ 'ਤੇ ਮਹੱਤਵਪੂਰਨ ਪ੍ਰਭਾਵ ਪਾ ਸਕਦਾ ਹੈ। ਨਿਰਮਾਣ ਉਦਯੋਗ ਨੂੰ ਮੰਗ ਕਰਦਾ ਹੈ ਕਿ ਮਸ਼ੀਨਰੀ ਮੰਗ ਵਾਲੀਆਂ ਸਥਿਤੀਆਂ ਹੇਠ ਲਗਾਤਾਰ ਪ੍ਰਦਰਸ਼ਨ ਪ੍ਰਦਾਨ ਕਰੇ ਜਦੋਂ ਕਿ ਹਜ਼ਾਰਾਂ ਬੈਂਡਿੰਗ ਚੱਕਰਾਂ ਵਿੱਚ ਸਹੀ ਵਿਸ਼ੇਸ਼ਤਾਵਾਂ ਨੂੰ ਬਰਕਰਾਰ ਰੱਖੇ।

ਸਟ੍ਰਕਚਰਲ ਇੰਜੀਨੀਅਰਿੰਗ ਅਤੇ ਫਰੇਮ ਡਿਜ਼ਾਈਨ

ਭਾਰੀ-ਡਿਊਟੀ ਫਰੇਮ ਨਿਰਮਾਣ

ਕਿਸੇ ਵੀ ਭਰੋਸੇਯੋਗ ਦਾ ਆਧਾਰ ਵੱਡੀ ਮੋੜਨ ਵਾਲੀ ਮਸ਼ੀਨ ਇਸਦੀ ਸੰਰਚਨਾਤਮਕ ਪੂਰਨਤਾ ਨਾਲ ਸ਼ੁਰੂ ਹੁੰਦਾ ਹੈ। ਪ੍ਰੀਮੀਅਮ ਮਸ਼ੀਨਾਂ ਵਿੱਚ ਉੱਚ-ਗ੍ਰੇਡ ਸਮੱਗਰੀ ਤੋਂ ਬਣੇ ਮਜ਼ਬੂਤ ਸਟੀਲ ਫਰੇਮ ਹੁੰਦੇ ਹਨ ਜੋ ਚਰਮ ਸੰਚਾਲਨ ਭਾਰ ਹੇਠ ਵਿਰੂਪਣ ਦਾ ਵਿਰੋਧ ਕਰਦੇ ਹਨ। ਝੁਕਣ ਦੇ ਕਾਰਜਾਂ ਦੌਰਾਨ ਪੈਦਾ ਹੋਏ ਮਹੱਤਵਪੂਰਨ ਬਲਾਂ ਨੂੰ ਸਹਿਣ ਕਰਨ ਲਈ ਫਰੇਮ ਡਿਜ਼ਾਈਨ ਨੂੰ ਮਸ਼ੀਨ ਦੇ ਸੇਵਾ ਜੀਵਨ ਕਾਲ ਦੌਰਾਨ ਆਯਾਮੀ ਸ਼ੁੱਧਤਾ ਬਰਕਰਾਰ ਰੱਖਣਾ ਚਾਹੀਦਾ ਹੈ। ਗੁਣਵੱਤਾ ਵਾਲੇ ਨਿਰਮਾਤਾ ਵੱਧ ਤੋਂ ਵੱਧ ਮਜ਼ਬੂਤੀ-ਓ-ਭਾਰ ਅਨੁਪਾਤ ਲਈ ਫਰੇਮ ਜਿਆਮਿਤੀ ਨੂੰ ਅਨੁਕੂਲਿਤ ਕਰਨ ਲਈ ਕੰਪਿਊਟਰ-ਐਡਿਡ ਡਿਜ਼ਾਈਨ ਅਤੇ ਫਾਈਨਿਟ ਐਲੀਮੈਂਟ ਵਿਸ਼ਲੇਸ਼ਣ ਦੀ ਵਰਤੋਂ ਕਰਦੇ ਹਨ।

ਉੱਨਤ ਫਰੇਮ ਕਾਨਫਿਗਰੇਸ਼ਨਾਂ ਵਿੱਚ ਰਣਨੀਤਕ ਤੌਰ 'ਤੇ ਸਥਿਤ ਮਜ਼ਬੂਤੀ ਦੇ ਪਸਲੀਆਂ ਅਤੇ ਤਣਾਅ ਵੰਡ ਚੈਨਲ ਸ਼ਾਮਲ ਹੁੰਦੇ ਹਨ ਜੋ ਉੱਚ-ਤਣਾਅ ਵਾਲੇ ਖੇਤਰਾਂ ਵਿੱਚ ਥਕਾਵਟ ਦੀ ਅਸਫਲਤਾ ਨੂੰ ਰੋਕਦੇ ਹਨ। ਫਰੇਮ ਕੰਪੋਨੈਂਟਸ ਦੀ ਵੈਲਡਿੰਗ ਦੀ ਗੁਣਵੱਤਾ ਲੰਬੇ ਸਮੇਂ ਦੀ ਭਰੋਸੇਯੋਗਤਾ ਨੂੰ ਸਿੱਧੇ ਤੌਰ 'ਤੇ ਪ੍ਰਭਾਵਿਤ ਕਰਦੀ ਹੈ, ਜਿਸ ਵਿੱਚ ਸਹੀ ਵੈਲਡਿੰਗ ਤਕਨੀਕਾਂ ਸਾਰੇ ਕੁਨੈਕਸ਼ਨ ਬਿੰਦੂਆਂ 'ਤੇ ਜੋੜ ਦੀ ਮਜ਼ਬੂਤੀ ਨੂੰ ਯਕੀਨੀ ਬਣਾਉਂਦੀਆਂ ਹਨ। ਉੱਤਮ ਫਰੇਮ ਡਿਜ਼ਾਈਨਾਂ ਵਿੱਚ ਮੋਡੀਊਲਰ ਨਿਰਮਾਣ ਵੀ ਸ਼ਾਮਲ ਹੁੰਦਾ ਹੈ ਜੋ ਢਾਂਚਾਗਤ ਬਣਤਰ ਨੂੰ ਨੁਕਸਾਨ ਪਹੁੰਚਾਏ ਬਿਨਾਂ ਮੁਰੰਮਤ ਐਕਸੈਸ ਅਤੇ ਸੰਭਾਵੀ ਭਵਿੱਖ ਦੇ ਅਪਗ੍ਰੇਡ ਲਈ ਸਹਾਇਤਾ ਕਰਦਾ ਹੈ।

ਕੰਪਨ ਦਮਨ ਅਤੇ ਸਥਿਰਤਾ

ਉੱਚ ਮਾਤਰਾ ਵਿੱਚ ਉਤਪਾਦਨ ਚੱਲਣ ਦੌਰਾਨ ਕਾਰਜਸ਼ੀਲ ਸਥਿਰਤਾ ਮਸ਼ੀਨ ਦੇ ਬੁਨਿਆਦੀ ਡਿਜ਼ਾਈਨ ਵਿੱਚ ਏਕੀਕ੍ਰਿਤ ਜਟਿਲ ਕੰਬਣੀ ਨਿਯੰਤਰਣ ਪ੍ਰਣਾਲੀਆਂ ਦੀ ਲੋੜ ਹੁੰਦੀ ਹੈ। ਗੁਣਵੱਤਾ ਯੁਕਤ ਵੱਡੇ ਪੈਮਾਨੇ 'ਤੇ ਮੋੜਨ ਵਾਲੀਆਂ ਮਸ਼ੀਨਾਂ ਵਿੱਚ ਆਈਸੋਲੇਸ਼ਨ ਮਾਊਂਟ ਅਤੇ ਡੈਪਨਿੰਗ ਤੰਤਰ ਸ਼ਾਮਲ ਹੁੰਦੇ ਹਨ ਜੋ ਆਸ ਪਾਸ ਦੇ ਸਾਮਾਨ ਅਤੇ ਸੁਵਿਧਾਵਾਂ ਦੀਆਂ ਬਣਤਰਾਂ ਨੂੰ ਕੰਬਣੀ ਦੇ ਸੰਚਾਰ ਨੂੰ ਘਟਾਉਂਦੇ ਹਨ। ਇਹ ਕੰਬਣੀ ਨਿਯੰਤਰਣ ਸਿੱਧੇ ਤੌਰ 'ਤੇ ਮੋੜਨ ਦੀ ਸ਼ੁੱਧਤਾ ਨੂੰ ਪ੍ਰਭਾਵਿਤ ਕਰਦਾ ਹੈ ਅਤੇ ਚੱਲ ਰਹੇ ਹਿੱਸਿਆਂ 'ਤੇ ਘਰਸਾਅ ਨੂੰ ਘਟਾ ਕੇ ਘਟਕਾਂ ਦੀ ਸੇਵਾ ਜੀਵਨ ਨੂੰ ਵਧਾਉਂਦਾ ਹੈ।

ਮਸ਼ੀਨ ਦਾ ਕੇਂਦਰ ਗੁਰੂਤਾ ਅਤੇ ਭਾਰ ਵੰਡ ਕਾਰਜ ਦੌਰਾਨ ਸਥਿਰਤਾ ਬਣਾਈ ਰੱਖਣ ਵਿੱਚ ਮਹੱਤਵਪੂਰਨ ਭੂਮਿਕਾ ਨਿਭਾਉਂਦੇ ਹਨ। ਚੰਗੀ ਤਰ੍ਹਾਂ ਇੰਜੀਨੀਅਰਡ ਡਿਜ਼ਾਈਨ ਭਾਰੀ ਘਟਕਾਂ ਨੂੰ ਫਰੇਮ ਢਾਂਚੇ ਦੇ ਹੇਠਲੇ ਹਿੱਸੇ ਵਿੱਚ ਸਥਾਪਿਤ ਕਰਦੀ ਹੈ, ਜਦੋਂ ਕਿ ਮਸ਼ੀਨ ਦੇ ਫੁਟਪ੍ਰਿੰਟ ਉੱਤੇ ਸੰਤੁਲਿਤ ਲੋਡ ਵੰਡ ਨੂੰ ਯਕੀਨੀ ਬਣਾਉਂਦੀ ਹੈ। ਇਹ ਸਾਵਧਾਨੀ ਨਾਲ ਕੀਤਾ ਗੁਰੂਤਾ ਪ੍ਰਬੰਧਨ ਕਾਰਜ ਦੌਰਾਨ ਮਸ਼ੀਨ ਦੀ ਹੋਂਦ ਨੂੰ ਰੋਕਦਾ ਹੈ ਅਤੇ ਵਿਆਪਕ ਬੁਨਿਆਦੀ ਤਿਆਰੀ ਦੀ ਲੋੜ ਨੂੰ ਘਟਾਉਂਦਾ ਹੈ।

ਪਾਵਰ ਸਿਸਟਮ ਅਤੇ ਡਰਾਈਵ ਮਕੈਨਿਜ਼ਮ

ਹਾਈਡ੍ਰੌਲਿਕ ਸਿਸਟਮ ਪ੍ਰਦਰਸ਼ਨ

ਹਾਈਡ੍ਰੌਲਿਕ ਸਿਸਟਮ ਜ਼ਿਆਦਾਤਰ ਉਦਯੋਗਿਕ ਪੱਧਰ 'ਤੇ ਵਰਤੇ ਜਾਣ ਵਾਲੇ ਬੈਂਡਿੰਗ ਮਸ਼ੀਨਾਂ ਦਾ ਦਿਲ ਹੁੰਦਾ ਹੈ, ਜੋ ਲਗਾਤਾਰ ਸਮੱਗਰੀ ਦੇ ਵਿਰੂਪਣ ਲਈ ਲੋੜੀਂਦੀ ਸ਼ਕਤੀ ਅਤੇ ਸ਼ੁੱਧਤਾ ਪ੍ਰਦਾਨ ਕਰਦਾ ਹੈ। ਪ੍ਰੀਮੀਅਮ ਹਾਈਡ੍ਰੌਲਿਕ ਸਿਸਟਮਾਂ ਵਿੱਚ ਵੱਡੇ ਪੰਪ ਅਤੇ ਰਿਜ਼ਰਵੇਅਰ ਹੁੰਦੇ ਹਨ ਜੋ ਲੰਬੇ ਸਮੇਂ ਤੱਕ ਚੱਲ ਰਹੇ ਆਪਰੇਟਿੰਗ ਚੱਕਰਾਂ ਦੌਰਾਨ ਲਗਾਤਾਰ ਦਬਾਅ ਬਣਾਈ ਰੱਖਦੇ ਹਨ। ਹਾਈਡ੍ਰੌਲਿਕ ਤਰਲ ਦੇ ਠੰਢਾ ਕਰਨ ਅਤੇ ਫਿਲਟਰੇਸ਼ਨ ਸਿਸਟਮ ਸੰਕ੍ਰਮਣ ਅਤੇ ਤਾਪਮਾਨ-ਸੰਬੰਧੀ ਪ੍ਰਦਰਸ਼ਨ ਵਿੱਚ ਕਮੀ ਨੂੰ ਰੋਕਦੇ ਹਨ ਜੋ ਬੈਂਡਿੰਗ ਸ਼ੁੱਧਤਾ ਨੂੰ ਖਰਾਬ ਕਰ ਸਕਦੇ ਹਨ।

ਅੱਗੇ ਵੱਧੇ ਦਬਾਅ ਨਿਯੰਤਰਣ ਵਾਲਵ ਅਤੇ ਪ੍ਰਵਾਹ ਨਿਯਮਨ ਸਿਸਟਮ ਬੈਂਡਿੰਗ ਕਾਰਜਾਂ ਦੌਰਾਨ ਸਹੀ ਤਾਕਤ ਲਾਗੂ ਕਰਨ ਦੀ ਆਗਿਆ ਦਿੰਦੇ ਹਨ। ਇਹ ਸਿਸਟਮ ਫੀਡਬੈਕ ਤੰਤਰਾਂ ਨੂੰ ਸ਼ਾਮਲ ਕਰਦੇ ਹਨ ਜੋ ਸਮੱਗਰੀ ਦੇ ਵਿਰੋਧ ਦੇ ਆਧਾਰ 'ਤੇ ਹਾਈਡ੍ਰੌਲਿਕ ਦਬਾਅ ਨੂੰ ਆਟੋਮੈਟਿਕ ਤੌਰ 'ਤੇ ਐਡਜਸਟ ਕਰਦੇ ਹਨ, ਜਿਸ ਨਾਲ ਸਮੱਗਰੀ ਵਿੱਚ ਤਬਦੀਲੀ ਦੇ ਬਾਵਜੂਦ ਲਗਾਤਾਰ ਬੈਂਡ ਐਂਗਲ ਯਕੀਨੀ ਬਣਾਏ ਜਾਂਦੇ ਹਨ। ਗੁਣਵੱਤਾ ਵਾਲੇ ਹਾਈਡ੍ਰੌਲਿਕ ਭਾਗਾਂ ਵਿੱਚ ਭਵਿੱਖਬਾਣੀ ਰੱਖ-ਰਖਾਅ ਦੀ ਸਮਰੱਥਾ ਵੀ ਹੁੰਦੀ ਹੈ ਜੋ ਸਿਸਟਮ ਦੇ ਪ੍ਰਦਰਸ਼ਨ ਨੂੰ ਮਾਨੀਟਰ ਕਰਦੀ ਹੈ ਅਤੇ ਅਸਫਲਤਾ ਆਉਣ ਤੋਂ ਪਹਿਲਾਂ ਆਪਰੇਟਰਾਂ ਨੂੰ ਸੰਭਾਵੀ ਮੁੱਦਿਆਂ ਬਾਰੇ ਚੇਤਾਵਨੀ ਦਿੰਦੀ ਹੈ।

ਮੋਟਰ ਅਤੇ ਟ੍ਰਾਂਸਮਿਸ਼ਨ ਇੰਟੀਗਰੇਸ਼ਨ

ਡਰਾਈਵ ਮੋਟਰ ਅਤੇ ਟਰਾਂਸਮਿਸ਼ਨ ਸਿਸਟਮ ਨੂੰ ਵੱਖ-ਵੱਖ ਵਕਰ ਓਪਰੇਸ਼ਨਜ਼ ਦੌਰਾਨ ਆਮਦ ਲੋਡ ਸਥਿਤੀਆਂ ਨੂੰ ਪੂਰਾ ਕਰਦੇ ਹੋਏ ਭਰੋਸੇਯੋਗ ਟੋਰਕ ਟਰਾਂਸਫਰ ਪ੍ਰਦਾਨ ਕਰਨਾ ਚਾਹੀਦਾ ਹੈ। ਪ੍ਰੀਮੀਅਮ ਮਸ਼ੀਨਾਂ ਸਰਵੋ ਮੋਟਰਾਂ ਦੀ ਵਰਤੋਂ ਕਰਦੀਆਂ ਹਨ ਜਿਨ੍ਹਾਂ ਵਿੱਚ ਇੰਟੀਗ੍ਰੇਟਿਡ ਐਨਕੋਡਰ ਹੁੰਦੇ ਹਨ ਜੋ ਸਹੀ ਸਥਿਤੀਗਤ ਫੀਡਬੈਕ ਪ੍ਰਦਾਨ ਕਰਦੇ ਹਨ ਅਤੇ ਸਹੀ ਵਕਰ ਕੋਣ ਨੂੰ ਨਿਯੰਤਰਿਤ ਕਰਨਾ ਸੰਭਵ ਬਣਾਉਂਦੇ ਹਨ। ਟਰਾਂਸਮਿਸ਼ਨ ਸਿਸਟਮ ਡਿਜ਼ਾਈਨ ਸਪੀਡ ਅਤੇ ਟੋਰਕ ਲੋੜਾਂ ਨੂੰ ਸੰਤੁਲਿਤ ਕਰਦਾ ਹੈ ਜਦੋਂ ਕਿ ਬੈਕਲਾਸ਼ ਨੂੰ ਘਟਾਉਂਦਾ ਹੈ ਜੋ ਵਕਰਨ ਦੀ ਸਹੀਤਾ ਨੂੰ ਪ੍ਰਭਾਵਿਤ ਕਰ ਸਕਦਾ ਹੈ।

ਊਰਜਾ ਕੁਸ਼ਲਤਾ ਦੇ ਵਿਚਾਰ ਵੱਡੇ ਪੱਧਰ 'ਤੇ ਓਪਰੇਸ਼ਨਜ਼ ਲਈ ਮੋਟਰ ਚੋਣ ਨੂੰ ਵਧਦੀ ਤਰਜੀਹ ਦਿੰਦੇ ਹਨ। ਆਧੁਨਿਕ ਮਸ਼ੀਨਾਂ ਵੇਰੀਏਬਲ ਫਰੀਕੁਐਂਸੀ ਡਰਾਈਵਜ਼ ਨੂੰ ਸ਼ਾਮਲ ਕਰਦੀਆਂ ਹਨ ਜੋ ਓਪਰੇਸ਼ਨਲ ਲੋੜਾਂ ਦੇ ਅਧਾਰ 'ਤੇ ਪਾਵਰ ਖਪਤ ਨੂੰ ਅਨੁਕੂਲ ਬਣਾਉਂਦੀਆਂ ਹਨ। ਇਹ ਸਿਸਟਮ ਊਰਜਾ ਲਾਗਤ ਨੂੰ ਘਟਾਉਂਦੇ ਹਨ ਜਦੋਂ ਕਿ ਘੱਟ ਥਰਮਲ ਤਣਾਅ ਅਤੇ ਸੁਧਰੀ ਓਪਰੇਸ਼ਨਲ ਕੁਸ਼ਲਤਾ ਰਾਹੀਂ ਮੋਟਰ ਦੀ ਸੇਵਾ ਜੀਵਨ ਨੂੰ ਵਧਾਉਂਦੇ ਹਨ।

ਕੰਟਰੋਲ ਸਿਸਟਮ ਅਤੇ ਆਟੋਮੇਸ਼ਨ ਫੀਚਰ

ਪ੍ਰੋਗਰਾਮੇਬਲ ਲੌਜਿਕ ਕੰਟਰੋਲਰ ਇੰਟੀਗ੍ਰੇਸ਼ਨ

ਕਾਲਪਨਿਕ ਵੱਡੀ ਮੋੜਨ ਵਾਲੀ ਮਸ਼ੀਨ ਸਿਸਟਮ ਜਟਿਲ ਮੋੜਨ ਦੀਆਂ ਲੜੀਆਂ ਅਤੇ ਸੁਰੱਖਿਆ ਪ੍ਰੋਟੋਕੋਲਾਂ ਨੂੰ ਪ੍ਰਬੰਧਿਤ ਕਰਨ ਵਾਲੇ ਜਟਿਲ ਪ੍ਰੋਗਰਾਮਯੋਗ ਲੌਜਿਕ ਕੰਟਰੋਲਰਾਂ 'ਤੇ ਨਿਰਭਰ ਕਰਦੇ ਹਨ। ਇਹ ਕੰਟਰੋਲ ਸਿਸਟਮ ਮੋੜਨ ਦੇ ਕਈ ਪ੍ਰੋਗਰਾਮਾਂ ਨੂੰ ਸਟੋਰ ਕਰਦੇ ਹਨ ਅਤੇ ਵੱਖ-ਵੱਖ ਉਤਪਾਦਨ ਲੋੜਾਂ ਵਿਚਕਾਰ ਤੇਜ਼ੀ ਨਾਲ ਬਦਲਾਅ ਕਰਨ ਦੀ ਆਗਿਆ ਦਿੰਦੇ ਹਨ। ਯੂਜ਼ਰ ਇੰਟਰਫੇਸ ਡਿਜ਼ਾਈਨ ਸੰਚਾਲਨ ਕੁਸ਼ਲਤਾ 'ਤੇ ਮਹੱਤਵਪੂਰਨ ਪ੍ਰਭਾਵ ਪਾਉਂਦਾ ਹੈ, ਜਿਸ ਵਿੱਚ ਸੁਰੱਖਿਅਤ ਟੱਚਸਕਰੀਨ ਡਿਸਪਲੇਅ ਮਸ਼ੀਨ ਦੀ ਸਥਿਤੀ ਅਤੇ ਉਤਪਾਦਨ ਪੈਰਾਮੀਟਰਾਂ ਬਾਰੇ ਸਪੱਸ਼ਟ ਪ੍ਰਤੀਕ੍ਰਿਆ ਪ੍ਰਦਾਨ ਕਰਦੇ ਹਨ।

ਉੱਨਤ ਕੰਟਰੋਲ ਸਿਸਟਮਾਂ ਵਿੱਚ ਰਿਅਲ-ਟਾਈਮ ਮਾਨੀਟਰਿੰਗ ਦੀ ਸਮਰੱਥਾ ਹੁੰਦੀ ਹੈ ਜੋ ਉਤਪਾਦਨ ਮੈਟ੍ਰਿਕਸ, ਸਮੱਗਰੀ ਦੀ ਵਰਤੋਂ ਅਤੇ ਉਪਕਰਣ ਪ੍ਰਦਰਸ਼ਨ ਸੂਚਕਾਂਕਾਂ ਨੂੰ ਟਰੈਕ ਕਰਦੀ ਹੈ। ਇਸ ਡਾਟਾ ਇਕੱਠਾ ਕਰਨ ਨਾਲ ਉਤਪਾਦਨ ਵਰਕਫਲੋਜ਼ ਦੀ ਭਵਿੱਖਬਾਣੀ ਅਤੇ ਅਨੁਕੂਲਨ ਦੀ ਯੋਜਨਾ ਬਣਾਉਣਾ ਸੰਭਵ ਹੁੰਦਾ ਹੈ। ਸੁਵਿਧਾ ਪ੍ਰਬੰਧਨ ਸਿਸਟਮਾਂ ਨਾਲ ਏਕੀਕਰਨ ਮਲਟੀਪਲ ਮਸ਼ੀਨਾਂ ਦੀ ਕੇਂਦਰੀਕ੍ਰਿਤ ਮਾਨੀਟਰਿੰਗ ਅਤੇ ਸੰਯੁਕਤ ਉਤਪਾਦਨ ਯੋਜਨਾਬੰਦੀ ਨੂੰ ਸੰਭਵ ਬਣਾਉਂਦਾ ਹੈ।

ਸੁਰੱਖਿਆ ਅਤੇ ਐਮਰਜੈਂਸੀ ਪ੍ਰਤੀਕ੍ਰਿਆ ਸਿਸਟਮ

ਵੱਡੇ ਪੈਮਾਨੇ 'ਤੇ ਮੋੜਨ ਵਾਲੇ ਸਾਜ਼ੋ-ਸਮਾਨ ਲਈ ਵਿਆਪਕ ਸੁਰੱਖਿਆ ਪ੍ਰਣਾਲੀਆਂ ਭਰੋਸੇਯੋਗ ਵਿਸ਼ੇਸ਼ਤਾਵਾਂ ਦਰਸਾਉਂਦੀਆਂ ਹਨ। ਆਧੁਨਿਕ ਮਸ਼ੀਨਾਂ ਵਿੱਚ ਰੌਸ਼ਨੀ ਦੇ ਪਰਦੇ, ਦਬਾਅ-ਸੰਵੇਦਨਸ਼ੀਲ ਗਲੀਚੇ, ਅਤੇ ਹੱਥੀਂ ਰੋਕਣ ਦੀਆਂ ਪ੍ਰਣਾਲੀਆਂ ਸਮੇਤ ਕਈ ਸੁਰੱਖਿਆ ਰੁਕਾਵਟਾਂ ਸ਼ਾਮਲ ਹੁੰਦੀਆਂ ਹਨ ਜੋ ਸੁਰੱਖਿਆ ਦੇ ਉਲਟਖੋਜ ਦੀ ਸੂਰਤ ਵਿੱਚ ਤੁਰੰਤ ਕਾਰਜ ਨੂੰ ਰੋਕ ਦਿੰਦੀਆਂ ਹਨ। ਸੁਰੱਖਿਆ ਪ੍ਰਣਾਲੀ ਦੀ ਡਿਜ਼ਾਈਨ ਨੂੰ ਆਪਰੇਟਰ ਦੀ ਸੁਰੱਖਿਆ ਅਤੇ ਉਤਪਾਦਨ ਦੀ ਕੁਸ਼ਲਤਾ ਦੇ ਵਿਚਕਾਰ ਸੰਤੁਲਨ ਬਣਾਏ ਰੱਖਣਾ ਚਾਹੀਦਾ ਹੈ, ਸੁਰੱਖਿਆ ਰੋਕਾਂ ਤੋਂ ਤੇਜ਼ੀ ਨਾਲ ਮੁੜ ਪ੍ਰਾਪਤ ਹੋਣਾ ਯਕੀਨੀ ਬਣਾਉਂਦੇ ਹੋਏ ਬਿਨਾਂ ਕਰਮਚਾਰੀ ਦੀ ਸੁਰੱਖਿਆ ਨੂੰ ਤਬਾਹ ਕੀਤੇ।

ਆਪਾਤਕਾਲੀਨ ਪ੍ਰਤੀਕਿਰਿਆ ਪ੍ਰੋਟੋਕੋਲ ਵਿੱਚ ਆਟੋਮੈਟਿਕ ਸਿਸਟਮ ਬੰਦ ਕਰਨ ਦੀਆਂ ਪ੍ਰਕਿਰਿਆਵਾਂ ਸ਼ਾਮਲ ਹੁੰਦੀਆਂ ਹਨ ਜੋ ਮਸ਼ੀਨ ਦੇ ਘਟਕਾਂ ਨੂੰ ਸੁਰੱਖਿਅਤ ਢੰਗ ਨਾਲ ਸਥਿਤੀ ਦੇਣ ਅਤੇ ਬਿਜਲੀ ਦੀ ਖਰਾਬੀ ਜਾਂ ਆਪਾਤਕਾਲੀਨ ਸਥਿਤੀਆਂ ਦੌਰਾਨ ਹਾਈਡ੍ਰੌਲਿਕ ਸਿਸਟਮਾਂ ਨੂੰ ਸੁਰੱਖਿਅਤ ਕਰਨ ਵਿੱਚ ਮਦਦ ਕਰਦੀਆਂ ਹਨ। ਆਪਾਤਕਾਲੀਨ ਰੋਕਾਂ ਅਤੇ ਸਥਿਤੀ ਨੂੰ ਬਰਕਰਾਰ ਰੱਖਣ ਦੀ ਯੋਗਤਾ ਨੂੰ ਬਿਜਲੀ ਦੀਆਂ ਰੁਕਾਵਟਾਂ ਦੌਰਾਨ ਕਾਰਜਸ਼ੀਲ ਰੱਖਣ ਲਈ ਮਹੱਤਵਪੂਰਨ ਸੁਰੱਖਿਆ ਕਾਰਜਾਂ ਲਈ ਬੈਕਅੱਪ ਪਾਵਰ ਸਿਸਟਮ ਦੀ ਲੋੜ ਹੋ ਸਕਦੀ ਹੈ।

ਸਮੱਗਰੀ ਨੂੰ ਸੰਭਾਲਣਾ ਅਤੇ ਸਥਿਤੀ ਨਿਰਧਾਰਤ ਕਰਨ ਵਾਲੀਆਂ ਪ੍ਰਣਾਲੀਆਂ

ਆਟੋਮੈਟਿਡ ਸਮੱਗਰੀ ਫੀਡ ਮਕੈਨਿਜ਼ਮ

ਕੁਸ਼ਲ ਸਮੱਗਰੀ ਹੈਂਡਲਿੰਗ ਪ੍ਰਣਾਲੀਆਂ ਸਹੀ ਮੋੜ ਕਾਰਜਾਂ ਲਈ ਨਿਰੰਤਰ ਸਮੱਗਰੀ ਦੀ ਸਥਿਤੀ ਨੂੰ ਯਕੀਨੀ ਬਣਾਉਂਦੇ ਹੋਏ ਮੈਨੂਅਲ ਹਸਤਕਸ਼ੇਪ ਨੂੰ ਘਟਾਉਂਦੀਆਂ ਹਨ। ਪ੍ਰੀਮੀਅਮ ਮਸ਼ੀਨਾਂ ਵਿੱਚ ਆਟੋਮੇਟਡ ਸਮੱਗਰੀ ਫੀਡ ਪ੍ਰਣਾਲੀਆਂ ਹੁੰਦੀਆਂ ਹਨ ਜੋ ਵੱਖ-ਵੱਖ ਸਮੱਗਰੀ ਦੇ ਆਕਾਰਾਂ ਅਤੇ ਕਨਫਿਗਰੇਸ਼ਨਾਂ ਨੂੰ ਬਿਨਾਂ ਵਧੀਆ ਸੈੱਟਅੱਪ ਤਬਦੀਲੀਆਂ ਦੀ ਲੋੜ ਦੇ ਸਮਰੂਪਤਾ ਪ੍ਰਦਾਨ ਕਰਦੀਆਂ ਹਨ। ਇਹ ਪ੍ਰਣਾਲੀਆਂ ਸੈਂਸਰਾਂ ਅਤੇ ਸਥਿਤੀ ਨਿਯੰਤਰਣਾਂ ਨੂੰ ਸ਼ਾਮਲ ਕਰਦੀਆਂ ਹਨ ਜੋ ਮੋੜ ਚੱਕਰਾਂ ਨੂੰ ਸ਼ੁਰੂ ਕਰਨ ਤੋਂ ਪਹਿਲਾਂ ਠੀਕ ਸਮੱਗਰੀ ਦੀ ਸਥਿਤੀ ਦੀ ਪੁਸ਼ਟੀ ਕਰਦੀਆਂ ਹਨ।

ਸਮੱਗਰੀ ਫੀਡ ਪ੍ਰਣਾਲੀ ਦੀ ਡਿਜ਼ਾਈਨ ਨੂੰ ਆਮ ਤੌਰ 'ਤੇ ਵੱਡੇ ਪੱਧਰ 'ਤੇ ਕਾਰਜਾਂ ਵਿੱਚ ਪ੍ਰੋਸੈਸ ਕੀਤੀ ਜਾਣ ਵਾਲੀ ਸਮੱਗਰੀ ਦੀ ਸੀਮਾ ਨੂੰ ਸਮਾਇਣਾ ਚਾਹੀਦਾ ਹੈ। ਐਡਜਸਟੇਬਲ ਗਾਈਡਾਂ ਅਤੇ ਸਹਾਇਤਾਵਾਂ ਸਮੱਗਰੀ ਦੀ ਠੀਕ ਸੰਰੇਖਣ ਨੂੰ ਯਕੀਨੀ ਬਣਾਉਂਦੀਆਂ ਹਨ ਜਦੋਂ ਕਿ ਮੁਕੰਮਲ ਸਤਹਾਂ ਨੂੰ ਨੁਕਸਾਨ ਤੋਂ ਰੋਕਿਆ ਜਾਂਦਾ ਹੈ। ਉੱਨਤ ਪ੍ਰਣਾਲੀਆਂ ਵਿੱਚ ਸਮੱਗਰੀ ਦਾ ਮਾਪ ਅਤੇ ਕੱਟਣ ਦੀ ਸਮਰੱਥਾ ਸ਼ਾਮਲ ਹੈ ਜੋ ਮੋੜ ਕਾਰਜਾਂ ਨਾਲ ਬਿਨਾਂ ਕਿਸੇ ਰੁਕਾਵਟ ਦੇ ਇਕੀਕ੍ਰਿਤ ਹੁੰਦੀ ਹੈ ਤਾਂ ਜੋ ਹੈਂਡਲਿੰਗ ਦੀਆਂ ਲੋੜਾਂ ਨੂੰ ਘਟਾਇਆ ਜਾ ਸਕੇ।

ਉਤਪਾਦ ਦਾ ਨਿਕਾਸ ਅਤੇ ਇਕੱਠਾ

ਸਵੈਚਾਲਿਤ ਉਤਪਾਦ ਨਿਕਾਸ ਪ੍ਰਣਾਲੀਆਂ ਉਤਪਾਦਨ ਪ੍ਰਵਾਹ ਨੂੰ ਬਰਕਰਾਰ ਰੱਖਦੀਆਂ ਹਨ ਜਦੋਂ ਕਿ ਅਗਲੇ ਪ੍ਰਸੰਸਕਰਣ ਜਾਂ ਪੈਕੇਜਿੰਗ ਲਈ ਮੁਕੰਮਲ ਘਟਕਾਂ ਨੂੰ ਵਿਵਸਥਿਤ ਕਰਦੀਆਂ ਹਨ। ਆਮ ਕਾਰਜਾਂ ਦੌਰਾਨ ਪੈਦਾ ਹੋਏ ਵੱਖ-ਵੱਖ ਵਕਰ ਸੰਰਚਨਾਵਾਂ ਨਾਲ ਨਜਿੱਠਣ ਲਈ ਇਹ ਪ੍ਰਣਾਲੀਆਂ ਮੁਕੰਮਲ ਉਤਪਾਦਾਂ ਨੂੰ ਨੁਕਸਾਨ ਪਹੁੰਚਾਏ ਬਿਨਾਂ ਕੰਮ ਕਰਨ ਦੇ ਯੋਗ ਹੋਣੀਆਂ ਚਾਹੀਦੀਆਂ ਹਨ। ਕਨਵੇਅਰ ਪ੍ਰਣਾਲੀਆਂ ਅਤੇ ਰੋਬੋਟਿਕ ਹੈਂਡਲਿੰਗ ਉਪਕਰਣ ਉਤਪਾਦ ਨੂੰ ਹਟਾਉਣ ਲਈ ਬਿਨਾਂ ਮਨੁੱਖੀ ਹਸਤਕਸ਼ੇਪ ਦੇ ਲਗਾਤਾਰ ਕਾਰਜ ਨੂੰ ਸੰਭਵ ਬਣਾਉਂਦੇ ਹਨ।

ਨਿਕਾਸ ਬਿੰਦੂ 'ਤੇ ਗੁਣਵੱਤਾ ਨਿਯੰਤਰਣ ਏਕੀਕਰਨ ਮੁਕੰਮਲ ਉਤਪਾਦਾਂ ਦੀ ਸਵੈਚਾਲਿਤ ਜਾਂਚ ਅਤੇ ਛਾਣਬੀਣ ਨੂੰ ਸੰਭਵ ਬਣਾਉਂਦਾ ਹੈ। ਵਿਜ਼ਨ ਪ੍ਰਣਾਲੀਆਂ ਅਤੇ ਮਾਪ ਮਾਪਣ ਦੇ ਉਪਕਰਣ ਝੁਕਾਅ ਕੋਣਾਂ ਅਤੇ ਸਮੁੱਚੀ ਉਤਪਾਦ ਗੁਣਵੱਤਾ ਦੀ ਪੁਸ਼ਟੀ ਕਰ ਸਕਦੇ ਹਨ ਜਦੋਂ ਉਤਪਾਦ ਮੁਕੰਮਲ ਮਾਲ ਇਨਵੈਂਟਰੀ ਵਿੱਚ ਦਾਖਲ ਹੁੰਦੇ ਹਨ। ਇਹ ਸਵੈਚਾਲਿਤ ਗੁਣਵੱਤਾ ਨਿਯੰਤਰਣ ਮਨੁੱਖੀ ਜਾਂਚ ਦੀਆਂ ਲੋੜਾਂ ਨੂੰ ਘਟਾਉਂਦਾ ਹੈ ਜਦੋਂ ਕਿ ਇਕਸਾਰ ਉਤਪਾਦ ਮਿਆਰਾਂ ਨੂੰ ਯਕੀਨੀ ਬਣਾਉਂਦਾ ਹੈ।

ਮੁਰੰਮਤ ਲਈ ਪਹੁੰਚ ਅਤੇ ਸੇਵਾ ਸਹਾਇਤਾ

ਘਟਕ ਪਹੁੰਚ ਅਤੇ ਸੇਵਾ ਯੋਗਤਾ

ਲੰਬੇ ਸਮੇਂ ਦੀ ਭਰੋਸੇਯੋਗਤਾ ਮੁੱਖ ਤੌਰ 'ਤੇ ਰੱਖ-ਰਖਾਅ ਦੀ ਪਹੁੰਚਯੋਗਤਾ ਅਤੇ ਘਟਕਾਂ ਦੀ ਸੇਵਾਯੋਗਤਾ ਡਿਜ਼ਾਈਨ 'ਤੇ ਨਿਰਭਰ ਕਰਦੀ ਹੈ। ਗੁਣਵੱਤਾ ਯੁਕਤ ਵੱਡੇ ਪੈਮਾਨੇ 'ਤੇ ਮੋੜਨ ਵਾਲੀਆਂ ਮਸ਼ੀਨਾਂ ਵਿੱਚ ਰਸਤੇ 'ਤੇ ਸਥਿਤ ਐਕਸੈਸ ਪੈਨਲ ਅਤੇ ਸੇਵਾ ਬਿੰਦੂ ਹੁੰਦੇ ਹਨ ਜੋ ਵਧੇਰੇ ਅਸੈਂਬਲੀ ਦੇ ਬਿਨਾਂ ਨਿਯਮਤ ਰੱਖ-ਰਖਾਅ ਨੂੰ ਸੰਭਵ ਬਣਾਉਂਦੇ ਹਨ। ਹਾਈਡ੍ਰੌਲਿਕ ਲਾਈਨਾਂ, ਬਿਜਲੀ ਦੇ ਕੰਡਿਊਟ ਅਤੇ ਮਕੈਨੀਕਲ ਘਟਕਾਂ ਦੀ ਵਿਵਸਥਾ ਜਾਂਚ ਅਤੇ ਬਦਲਾਅ ਦੀਆਂ ਗਤੀਵਿਧੀਆਂ ਨੂੰ ਸੁਗਮ ਬਣਾਉਂਦੀ ਹੈ।

ਮੋਡੀਊਲਰ ਘਟਕ ਡਿਜ਼ਾਈਨ ਆਸ ਪਾਸ ਦੀਆਂ ਪ੍ਰਣਾਲੀਆਂ ਨੂੰ ਪ੍ਰਭਾਵਿਤ ਕੀਤੇ ਬਿਨਾਂ ਪਹਿਨਣ ਵਾਲੀਆਂ ਵਸਤੂਆਂ ਅਤੇ ਮੁੱਖ ਘਟਕਾਂ ਦੀ ਕੁਸ਼ਲ ਤਬਦੀਲੀ ਨੂੰ ਸੰਭਵ ਬਣਾਉਂਦਾ ਹੈ। ਮਿਆਰੀ ਫਾਸਟਨਰ ਅਤੇ ਕੁਨੈਕਸ਼ਨ ਢੰਗ ਰੱਖ-ਰਖਾਅ ਗਤੀਵਿਧੀਆਂ ਲਈ ਲੋੜੀਂਦੇ ਔਜ਼ਾਰਾਂ ਦੀ ਕਿਸਮ ਨੂੰ ਘਟਾਉਂਦੇ ਹਨ। ਸਪੱਸ਼ਟ ਘਟਕ ਲੇਬਲਿੰਗ ਅਤੇ ਦਸਤਾਵੇਜ਼ੇਸ਼ਨ ਕੁਸ਼ਲ ਸਮੱਸਿਆ ਨਿਵਾਰਣ ਅਤੇ ਮੁਰੰਮਤ ਪ੍ਰਕਿਰਿਆਵਾਂ ਨੂੰ ਸਮਰਥਨ ਦਿੰਦੇ ਹਨ।

ਡਾਇਗਨੌਸਟਿਕ ਅਤੇ ਮਾਨੀਟਰਿੰਗ ਸਮਰੱਥਾਵਾਂ

ਤਰੱਕੀ ਯਾਫ਼ਤਾ ਨੈਦਾਨਿਕ ਪ੍ਰਣਾਲੀਆਂ ਮਸ਼ੀਨ ਦੇ ਮਹੱਤਵਪੂਰਨ ਪੈਰਾਮੀਟਰਾਂ ਅਤੇ ਘਟਕਾਂ ਦੀ ਸਥਿਤੀ 'ਤੇ ਅਸਲ ਸਮੇਂ ਵਿੱਚ ਨਿਗਰਾਨੀ ਪ੍ਰਦਾਨ ਕਰਦੀਆਂ ਹਨ। ਇਹ ਪ੍ਰਣਾਲੀਆਂ ਹਾਈਡ੍ਰੌਲਿਕ ਦਬਾਅ, ਮੋਟਰ ਦਾ ਤਾਪਮਾਨ, ਕੰਪਨ ਦੇ ਪੱਧਰ ਅਤੇ ਹੋਰ ਪ੍ਰਦਰਸ਼ਨ ਸੰਕੇਤਕ ਜੋ ਸੰਭਾਵੀ ਰੱਖ-ਰਖਾਅ ਦੀਆਂ ਲੋੜਾਂ ਨੂੰ ਦਰਸਾਉਂਦੇ ਹਨ, ਨੂੰ ਟਰੈਕ ਕਰਦੀਆਂ ਹਨ। ਭਵਿੱਖਬਾਣੀ ਰੱਖ-ਰਖਾਅ ਐਲਗੋਰਿਦਮ ਕਾਰਜਸ਼ੀਲ ਡਾਟਾ ਦਾ ਵਿਸ਼ਲੇਸ਼ਣ ਕਰਦੇ ਹਨ ਤਾਂ ਜੋ ਸੇਵਾ ਦੇ ਅੰਤਰਾਲਾਂ ਅਤੇ ਘਟਕਾਂ ਦੀ ਬਦਲੋ ਦੀ ਸੂਚੀ ਲਈ ਇਸ਼ਾਰਾ ਕੀਤਾ ਜਾ ਸਕੇ।

ਰਿਮੋਟ ਮਾਨੀਟਰਿੰਗ ਸਮਰੱਥਾਵਾਂ ਸੇਵਾ ਤਕਨੀਸ਼ੀਅਨਾਂ ਨੂੰ ਮੁੱਦਿਆਂ ਦਾ ਨੈਦਾਨ ਲਗਾਉਣ ਅਤੇ ਸਾਈਟ 'ਤੇ ਜਾਣ ਤੋਂ ਬਿਨਾਂ ਸਹਾਇਤਾ ਪ੍ਰਦਾਨ ਕਰਨ ਦੀ ਆਗਿਆ ਦਿੰਦੀਆਂ ਹਨ। ਇਹ ਕਨੈਕਟੀਵਿਟੀ ਡਾਊਨਟਾਈਮ ਨੂੰ ਘਟਾਉਂਦੀ ਹੈ ਅਤੇ ਅਸਲ ਮਸ਼ੀਨ ਦੀਆਂ ਸਥਿਤੀਆਂ ਦੇ ਆਧਾਰ 'ਤੇ ਪਹਿਲ ਤੋਂ ਰੱਖ-ਰਖਾਅ ਦੀ ਸਕਿਡਿਊਲਿੰਗ ਨੂੰ ਸੰਭਵ ਬਣਾਉਂਦੀ ਹੈ, ਨਿਰਧਾਰਤ ਸਮੇਂ ਦੇ ਅੰਤਰਾਲਾਂ ਦੀ ਬਜਾਏ। ਨਿਰਮਾਤਾ ਸਮਰਥਨ ਪ੍ਰਣਾਲੀਆਂ ਨਾਲ ਇਕੀਕਰਨ ਤਕਨੀਕੀ ਮਾਹਿਰਤਾ ਅਤੇ ਬਦਲਾਅ ਵਾਲੇ ਹਿੱਸਿਆਂ ਦੀ ਆਰਡਰਿੰਗ ਤੱਕ ਪਹੁੰਚ ਪ੍ਰਦਾਨ ਕਰਦਾ ਹੈ।

ਅਕਸਰ ਪੁੱਛੇ ਜਾਣ ਵਾਲੇ ਸਵਾਲ

ਵੱਡੇ ਪੈਮਾਨੇ 'ਤੇ ਮੋੜਨ ਵਾਲੀ ਮਸ਼ੀਨ ਚੁਣਦੇ ਸਮੇਂ ਕਿਹੜੇ ਸਮਰੱਥਾ ਵਿਚਾਰ ਮਹੱਤਵਪੂਰਨ ਹੁੰਦੇ ਹਨ

ਕੈਪੇਸਿਟੀ ਚੋਣ ਵਿੱਚ ਵੱਧ ਤੋਂ ਵੱਧ ਸਮੱਗਰੀ ਦੇ ਮਾਪ, ਮੋੜਨ ਦੀ ਲੋੜ ਵਾਲੀ ਫੋਰਸ, ਅਤੇ ਉਤਪਾਦਨ ਮਾਤਰਾ ਦੀਆਂ ਉਮੀਦਾਂ ਦਾ ਸਾਵਧਾਨੀ ਨਾਲ ਵਿਸ਼ਲੇਸ਼ਣ ਕਰਨਾ ਜ਼ਰੂਰੀ ਹੈ। ਮਸ਼ੀਨ ਦੀਆਂ ਵਿਸ਼ੇਸ਼ਤਾਵਾਂ ਦਾ ਮੁਲਾਂਕਣ ਕਰਦੇ ਸਮੇਂ ਮੌਜੂਦਾ ਲੋੜਾਂ ਅਤੇ ਭਵਿੱਖੀ ਵਾਧੇ ਦੀਆਂ ਉਮੀਦਾਂ ਦੋਵਾਂ ਬਾਰੇ ਵਿਚਾਰ ਕਰੋ। ਮਸ਼ੀਨ ਦੀ ਡਿਊਟੀ ਚੱਕਰ ਰੇਟਿੰਗ ਚੋਟੀ ਦੀ ਉਤਪਾਦਨ ਮੰਗ ਨੂੰ ਪੂਰਾ ਕਰਨ ਦੇ ਯੋਗ ਹੋਣੀ ਚਾਹੀਦੀ ਹੈ ਅਤੇ ਲੰਬੇ ਸਮੇਂ ਤੱਕ ਚੱਲ ਰਹੇ ਕੰਮਕਾਜ ਦੌਰਾਨ ਲਗਾਤਾਰ ਪ੍ਰਦਰਸ਼ਨ ਬਰਕਰਾਰ ਰੱਖਣਾ ਚਾਹੀਦਾ ਹੈ।

ਵੱਡੇ ਪੈਮਾਨੇ 'ਤੇ ਮੋੜਨ ਵਾਲੀ ਮਸ਼ੀਨ ਦੇ ਪ੍ਰਦਰਸ਼ਨ 'ਤੇ ਮਾਹੌਲਿਕ ਹਾਲਤਾਂ ਦਾ ਕੀ ਪ੍ਰਭਾਵ ਪੈਂਦਾ ਹੈ

ਤਾਪਮਾਨ ਵਿੱਚ ਤਬਦੀਲੀ, ਨਮੀ ਦੇ ਪੱਧਰ ਅਤੇ ਧੂੜ ਦੇ ਸੰਪਰਕ ਸਮੇਤ ਮਾਹੌਲਿਕ ਕਾਰਕ ਮਸ਼ੀਨ ਦੀ ਭਰੋਸੇਯੋਗਤਾ ਅਤੇ ਸਹੀਤਾ 'ਤੇ ਮਹੱਤਵਪੂਰਨ ਪ੍ਰਭਾਵ ਪਾਉਂਦੇ ਹਨ। ਪ੍ਰੀਮੀਅਮ ਮਸ਼ੀਨਾਂ ਵਿੱਚ ਮਾਹੌਲਿਕ ਸੁਰੱਖਿਆ ਪ੍ਰਣਾਲੀਆਂ ਅਤੇ ਤਾਪਮਾਨ ਭਰਪਾਈ ਦੀਆਂ ਵਿਸ਼ੇਸ਼ਤਾਵਾਂ ਸ਼ਾਮਲ ਹੁੰਦੀਆਂ ਹਨ ਜੋ ਵੱਖ-ਵੱਖ ਕੰਮਕਾਜ ਹਾਲਤਾਂ ਵਿੱਚ ਪ੍ਰਦਰਸ਼ਨ ਦੀ ਲਗਾਤਾਰਤਾ ਬਰਕਰਾਰ ਰੱਖਦੀਆਂ ਹਨ। ਸਹੀ ਸੁਵਿਧਾ ਮਾਹੌਲਿਕ ਨਿਯੰਤਰਣ ਉਪਕਰਣਾਂ ਦੀ ਸੇਵਾ ਜੀਵਨ ਨੂੰ ਵਧਾਉਂਦੇ ਹਨ ਅਤੇ ਰੱਖ-ਰਖਾਅ ਦੀਆਂ ਲੋੜਾਂ ਨੂੰ ਘਟਾਉਂਦੇ ਹਨ।

ਵੱਡੇ ਪੈਮਾਨੇ 'ਤੇ ਮੋੜਨ ਵਾਲੀ ਮਸ਼ੀਨ ਦੇ ਆਪਰੇਟਰਾਂ ਲਈ ਕਿਹੜੀਆਂ ਟਰੇਨਿੰਗ ਲੋੜਾਂ ਨੂੰ ਧਿਆਨ ਵਿੱਚ ਰੱਖਣਾ ਚਾਹੀਦਾ ਹੈ

ਮਸ਼ੀਨ ਚਲਾਉਣ, ਸੁਰੱਖਿਆ ਪ੍ਰੋਟੋਕੋਲ, ਨਿਯਮਤ ਰੱਖ-ਰਖਾਅ ਪ੍ਰਕਿਰਿਆਵਾਂ ਅਤੇ ਬੁਨਿਆਦੀ ਸਮੱਸਿਆ ਹੱਲ ਕਰਨ ਦੀਆਂ ਤਕਨੀਕਾਂ ਨੂੰ ਸ਼ਾਮਲ ਕਰਨਾ ਚਾਹੀਦਾ ਹੈ। ਆਧੁਨਿਕ ਨਿਯੰਤਰਣ ਪ੍ਰਣਾਲੀਆਂ ਦੀ ਜਟਿਲਤਾ ਸੰਚਾਲਨ ਦੀ ਕੁਸ਼ਲਤਾ ਨੂੰ ਵੱਧ ਤੋਂ ਵੱਧ ਕਰਨ ਅਤੇ ਸੁਰੱਖਿਆ ਮਿਆਰਾਂ ਨੂੰ ਬਰਕਰਾਰ ਰੱਖਣ ਲਈ ਲਗਾਤਾਰ ਸਿੱਖਿਆ ਦੀ ਲੋੜ ਹੁੰਦੀ ਹੈ। ਨਿਯਮਤ ਸਿਖਲਾਈ ਅਪਡੇਟ ਯਕੀਨੀ ਬਣਾਉਂਦੇ ਹਨ ਕਿ ਆਪਰੇਟਰ ਉਪਕਰਣ ਦੀਆਂ ਯੋਗਤਾਵਾਂ ਅਤੇ ਵਧੀਆ ਪ੍ਰਥਾਵਾਂ ਨਾਲ ਅਪ ਟੂ ਡੇਟ ਰਹਿੰਦੇ ਹਨ।

ਵੱਡੇ ਪੈਮਾਨੇ 'ਤੇ ਮੋੜਨ ਵਾਲੇ ਉਪਕਰਣਾਂ ਨਾਲ ਉਤਪਾਦਨ ਦੀ ਕੁਸ਼ਲਤਾ ਨੂੰ ਕਿਵੇਂ ਅਨੁਕੂਲ ਬਣਾਇਆ ਜਾ ਸਕਦਾ ਹੈ

ਉਤਪਾਦਨ ਦੀ ਅਨੁਕੂਲਤਾ ਸਮੱਗਰੀ ਦੇ ਪ੍ਰਵਾਹ, ਪ੍ਰੋਗਰਾਮ ਸੈੱਟਅਪ ਦੀ ਕੁਸ਼ਲਤਾ ਅਤੇ ਰੱਖ-ਰਖਾਅ ਦੀ ਸ਼ਡਿਊਲਿੰਗ 'ਤੇ ਧਿਆਨ ਦੇਣ ਨਾਲ ਹੁੰਦੀ ਹੈ। ਆਟੋਮੇਟਿਡ ਸਮੱਗਰੀ ਹੈਂਡਲਿੰਗ ਪ੍ਰਣਾਲੀਆਂ ਚੱਕਰ ਦੇ ਸਮੇਂ ਨੂੰ ਘਟਾਉਂਦੀਆਂ ਹਨ ਜਦੋਂ ਕਿ ਲਗਾਤਾਰ ਗੁਣਵੱਤਾ ਬਰਕਰਾਰ ਰੱਖਦੀਆਂ ਹਨ। ਉਤਪਾਦਨ ਡੇਟਾ ਦਾ ਨਿਯਮਤ ਵਿਸ਼ਲੇਸ਼ਣ ਪ੍ਰਕਿਰਿਆ ਵਿੱਚ ਸੁਧਾਰ ਅਤੇ ਉਪਕਰਣਾਂ ਵਿੱਚ ਅਪਗ੍ਰੇਡ ਕਰਨ ਦੇ ਮੌਕਿਆਂ ਨੂੰ ਪਛਾਣਦਾ ਹੈ ਜੋ ਸਮੁੱਚੀ ਸੰਚਾਲਨ ਕੁਸ਼ਲਤਾ ਨੂੰ ਵਧਾਉਂਦੇ ਹਨ।

ਸਮੱਗਰੀ

- ਸਟ੍ਰਕਚਰਲ ਇੰਜੀਨੀਅਰਿੰਗ ਅਤੇ ਫਰੇਮ ਡਿਜ਼ਾਈਨ

- ਪਾਵਰ ਸਿਸਟਮ ਅਤੇ ਡਰਾਈਵ ਮਕੈਨਿਜ਼ਮ

- ਕੰਟਰੋਲ ਸਿਸਟਮ ਅਤੇ ਆਟੋਮੇਸ਼ਨ ਫੀਚਰ

- ਸਮੱਗਰੀ ਨੂੰ ਸੰਭਾਲਣਾ ਅਤੇ ਸਥਿਤੀ ਨਿਰਧਾਰਤ ਕਰਨ ਵਾਲੀਆਂ ਪ੍ਰਣਾਲੀਆਂ

- ਮੁਰੰਮਤ ਲਈ ਪਹੁੰਚ ਅਤੇ ਸੇਵਾ ਸਹਾਇਤਾ

-

ਅਕਸਰ ਪੁੱਛੇ ਜਾਣ ਵਾਲੇ ਸਵਾਲ

- ਵੱਡੇ ਪੈਮਾਨੇ 'ਤੇ ਮੋੜਨ ਵਾਲੀ ਮਸ਼ੀਨ ਚੁਣਦੇ ਸਮੇਂ ਕਿਹੜੇ ਸਮਰੱਥਾ ਵਿਚਾਰ ਮਹੱਤਵਪੂਰਨ ਹੁੰਦੇ ਹਨ

- ਵੱਡੇ ਪੈਮਾਨੇ 'ਤੇ ਮੋੜਨ ਵਾਲੀ ਮਸ਼ੀਨ ਦੇ ਪ੍ਰਦਰਸ਼ਨ 'ਤੇ ਮਾਹੌਲਿਕ ਹਾਲਤਾਂ ਦਾ ਕੀ ਪ੍ਰਭਾਵ ਪੈਂਦਾ ਹੈ

- ਵੱਡੇ ਪੈਮਾਨੇ 'ਤੇ ਮੋੜਨ ਵਾਲੀ ਮਸ਼ੀਨ ਦੇ ਆਪਰੇਟਰਾਂ ਲਈ ਕਿਹੜੀਆਂ ਟਰੇਨਿੰਗ ਲੋੜਾਂ ਨੂੰ ਧਿਆਨ ਵਿੱਚ ਰੱਖਣਾ ਚਾਹੀਦਾ ਹੈ

- ਵੱਡੇ ਪੈਮਾਨੇ 'ਤੇ ਮੋੜਨ ਵਾਲੇ ਉਪਕਰਣਾਂ ਨਾਲ ਉਤਪਾਦਨ ਦੀ ਕੁਸ਼ਲਤਾ ਨੂੰ ਕਿਵੇਂ ਅਨੁਕੂਲ ਬਣਾਇਆ ਜਾ ਸਕਦਾ ਹੈ