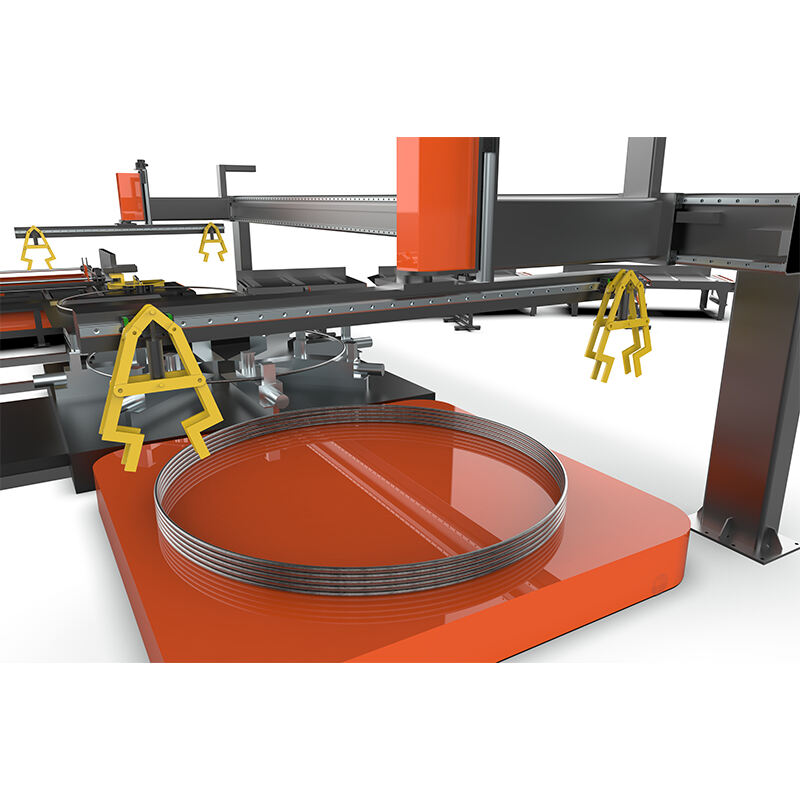

Modern construction projects demand unprecedented precision and efficiency when working with heavy steel reinforcement materials. The evolution of construction technology has brought forth sophisticated equipment capable of handling massive structural components with remarkable accuracy. Engineering teams across the globe are increasingly relying on automated solutions to meet the growing demands of infrastructure development, where traditional manual methods simply cannot deliver the required speed and consistency.

The complexity of contemporary construction projects requires equipment that can process various steel bar diameters while maintaining structural integrity throughout the bending process. Construction professionals understand that the foundation of any successful project lies in the quality and precision of reinforcement work. This critical aspect directly impacts the longevity and safety of structures, making equipment selection a paramount concern for project managers and engineers alike.

Engineering Capabilities of Heavy-Duty Construction Equipment

Advanced Hydraulic Systems for Maximum Force Generation

Industrial hydraulic technology forms the backbone of modern heavy-duty bending equipment, enabling these machines to generate tremendous force while maintaining precise control. The sophisticated hydraulic systems incorporated in large-scale bending machines utilize multiple cylinders working in synchronization to distribute force evenly across the material being processed. This distributed force application prevents stress concentration points that could compromise the structural integrity of reinforcement bars.

The pressure regulation systems within these hydraulic networks allow operators to fine-tune the applied force based on material specifications and project requirements. Advanced pressure sensors continuously monitor system performance, automatically adjusting parameters to maintain consistent bending angles regardless of material variations. This level of automation significantly reduces the potential for human error while ensuring that each bent component meets exact specifications.

Temperature compensation mechanisms within hydraulic systems account for thermal expansion and contraction effects that could otherwise impact bending accuracy. These systems maintain optimal operating temperatures through integrated cooling circuits, ensuring consistent performance throughout extended operation periods. The reliability of these hydraulic systems directly translates to improved project timelines and reduced maintenance costs.

Precision Control Mechanisms and Automated Programming

Computer-controlled positioning systems enable large-scale bending machines to achieve remarkable accuracy in angle formation and dimensional consistency. These control systems utilize advanced servo motors and encoder feedback mechanisms to monitor and adjust positioning in real-time. The integration of programmable logic controllers allows operators to store multiple bending sequences, enabling rapid setup changes between different project requirements.

Digital measurement systems incorporated within these machines provide instant feedback on bending angles, eliminating the need for manual verification and reducing processing time. Laser measurement technology ensures that each bend meets specified tolerances, with automatic rejection systems identifying and segregating non-conforming pieces. This level of quality control maintains consistency across large production runs while minimizing material waste.

The programmable nature of modern control systems allows for complex bending sequences that would be impossible to achieve through manual methods. Multi-axis coordination enables the creation of three-dimensional shapes with compound angles, expanding the design possibilities for architects and structural engineers. These capabilities open new avenues for innovative construction techniques and architectural expressions.

Load Capacity and Material Handling Excellence

Structural Design for Heavy Load Management

The foundational structure of industrial bending equipment must withstand enormous forces generated during the processing of heavy construction materials. Robust steel frame construction, often utilizing high-strength alloys, provides the necessary rigidity to prevent deflection under maximum load conditions. Engineering calculations for these machines account for dynamic loading scenarios, ensuring structural integrity throughout the operational lifecycle.

Reinforcement patterns within machine frames distribute stress loads across multiple load paths, preventing failure points that could compromise operational safety. The strategic placement of structural supports and cross-bracing elements creates a framework capable of handling materials ranging from standard reinforcement bars to heavy structural steel sections. This design philosophy ensures that large-scale bending machines can accommodate the diverse material requirements found in modern construction projects.

Foundation mounting systems for these machines require specialized installation procedures to ensure proper load transfer to supporting structures. The integration of vibration dampening systems reduces transmission of operational forces to surrounding equipment and structures. These considerations are particularly important in facility planning where multiple heavy machines operate in proximity.

Material Feeding and Positioning Systems

Automated material handling systems integrated with large-scale bending machines streamline the processing workflow while reducing manual labor requirements. Conveyor systems capable of supporting substantial material weights ensure smooth material flow from storage areas to processing stations. These systems incorporate safety mechanisms to prevent material damage during transportation and positioning phases.

Precision positioning mechanisms utilize advanced sensor technology to accurately locate materials within the bending zone prior to processing. Adjustable clamping systems accommodate various material cross-sections while ensuring secure retention during bending operations. The versatility of these positioning systems allows for rapid changeover between different material specifications without extensive setup procedures.

Length measurement systems automatically calculate material requirements for each bending operation, optimizing material utilization and reducing waste. Integration with inventory management systems provides real-time tracking of material consumption and project progress. These capabilities enhance project planning accuracy and cost control throughout the construction process.

Performance Optimization in Construction Applications

Speed and Efficiency Enhancements

Modern large-scale bending machines incorporate rapid cycle technologies that significantly reduce processing times compared to traditional methods. Advanced motion control algorithms optimize machine movements to minimize idle time between bending operations. The synchronization of multiple machine axes allows for simultaneous positioning and bending actions, further reducing cycle times.

Quick-change tooling systems enable operators to switch between different bending configurations with minimal downtime. Standardized tool interfaces and automated tool recognition systems eliminate setup errors and reduce changeover time requirements. These features are particularly valuable in construction environments where project schedules demand maximum equipment utilization.

Predictive maintenance systems monitor machine performance parameters to identify potential issues before they impact production schedules. Integrated diagnostic capabilities provide detailed information about component wear and system performance trends. This proactive approach to maintenance scheduling minimizes unexpected downtime and extends equipment service life.

Quality Assurance and Consistency Metrics

Statistical process control systems integrated within large-scale bending machines continuously monitor production quality metrics and maintain detailed records of each processed component. These systems track dimensional accuracy, bending angles, and material properties throughout production runs. Real-time quality data enables immediate corrective actions when variations exceed acceptable tolerances.

Automated inspection systems utilize advanced sensor technology to verify component dimensions and geometric accuracy immediately following the bending process. Vision systems can detect surface defects or material irregularities that might compromise structural performance. These inspection capabilities ensure that only conforming components proceed to installation phases.

Documentation systems generate detailed reports for each production batch, providing traceability information required for quality certification and regulatory compliance. Integration with project management systems enables real-time progress tracking and resource allocation optimization. These data management capabilities support continuous improvement initiatives and performance benchmarking.

Integration with Modern Construction Workflows

Digital Connectivity and Industry 4.0 Implementation

Contemporary large-scale bending machines feature extensive connectivity options that enable seamless integration with digital construction management platforms. Industrial internet protocols allow real-time data exchange between equipment and central control systems. This connectivity enables remote monitoring capabilities and supports predictive analytics applications that optimize production scheduling.

Cloud-based data storage systems maintain comprehensive production histories and performance metrics accessible from any location with internet connectivity. Mobile applications provide operators and managers with instant access to machine status information and production reports. These digital tools enhance communication and coordination between project stakeholders.

Integration with building information modeling systems enables direct transfer of design specifications to machine control systems, eliminating manual data entry errors and reducing setup time. Automated work order generation based on project schedules ensures optimal resource utilization throughout construction phases. These digital workflows represent the future of construction automation and efficiency optimization.

Safety Systems and Operational Protection

Comprehensive safety systems integrated within large-scale bending machines protect operators and equipment through multiple layers of protection mechanisms. Emergency stop systems provide immediate shutdown capabilities from multiple locations around the machine. Light curtain systems detect operator presence within dangerous zones and automatically halt machine operations.

Lockout-tagout procedures are facilitated through electronic control systems that prevent unauthorized machine startup during maintenance activities. Visual and audible warning systems alert personnel to machine status changes and potential hazard conditions. These safety measures comply with international safety standards and regulatory requirements.

Operator training systems provide interactive instruction modules that ensure proper machine operation and safety protocol compliance. Certification tracking systems maintain records of operator qualifications and training completion status. These training capabilities support workforce development initiatives and maintain consistent operational standards.

FAQ

What load capacities can modern large-scale bending machines handle

Modern large-scale bending machines are engineered to handle reinforcement bars ranging from 6mm to 50mm in diameter, with some specialized units capable of processing even larger structural steel sections. The maximum load capacity varies by model, but industrial-grade machines typically generate bending forces between 50 to 200 tons. These machines can process materials with tensile strengths up to 600 MPa while maintaining precise bending angles within ±0.5 degrees tolerance.

How do these machines ensure consistent quality across large production runs

Quality consistency is maintained through integrated control systems that monitor and adjust bending parameters in real-time based on material feedback and predetermined specifications. Advanced sensor technology continuously measures bending angles and dimensions during processing, with automatic corrections applied when variations are detected. Statistical process control systems track quality metrics throughout production runs, ensuring that dimensional tolerances remain within acceptable limits regardless of production volume.

What maintenance requirements are associated with heavy-duty bending equipment

Preventive maintenance schedules for large-scale bending machines typically include daily lubrication checks, weekly hydraulic system inspections, and monthly calibration verification procedures. Critical components such as hydraulic pumps, servo motors, and control systems require periodic replacement based on operating hours and performance monitoring data. Predictive maintenance systems provide advance warning of component wear, allowing maintenance activities to be scheduled during planned downtime periods to minimize production disruption.

How do these machines integrate with existing construction management systems

Integration capabilities include standard industrial communication protocols such as Ethernet/IP, Profinet, and OPC-UA that enable seamless data exchange with existing enterprise resource planning and project management systems. Real-time production data can be automatically transferred to inventory management systems, updating material consumption and project progress status. Mobile connectivity options allow remote monitoring and control capabilities, enabling supervisors to track equipment performance and production metrics from any location with internet access.

Table of Contents

- Engineering Capabilities of Heavy-Duty Construction Equipment

- Load Capacity and Material Handling Excellence

- Performance Optimization in Construction Applications

- Integration with Modern Construction Workflows

-

FAQ

- What load capacities can modern large-scale bending machines handle

- How do these machines ensure consistent quality across large production runs

- What maintenance requirements are associated with heavy-duty bending equipment

- How do these machines integrate with existing construction management systems